![Hands on with the ANET ET4 [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08efa12a4e.jpg) Hands on with the ANET ET4 [Source: Fabbaloo]

Hands on with the ANET ET4 [Source: Fabbaloo]

We were fortunate to obtain a brand-new ANET ET4 3D printer and spent some time giving it a good test.

This is part 3 of a 3 part series:

Custom 3D Prints on the ET4

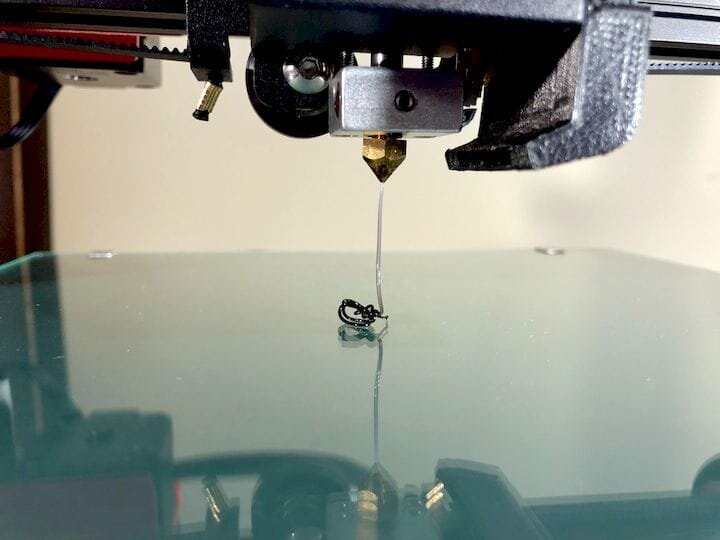

![My first extrusion on the ANET ET4 [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08efa59849.jpg) My first extrusion on the ANET ET4 [Source: Fabbaloo]

My first extrusion on the ANET ET4 [Source: Fabbaloo]

ANET includes several sample print files that are pretty much guaranteed to print correctly.

Of course, a 3D printer is most useful when you can print your own 3D models, as the provided samples are not particularly interesting after you print them once.

For that you’ll need to set up some software on your PC.

ANET recommends using Cura or Simplify3D as slicing software for the ET4 3D printer. They provide a version of Cura on their microUSB, so I tried to get it off the stick. ANET provides an adapter USB contraption to mount the microSD card on, thus turning it into a regular USB-A device.

Unfortunately, there was something amiss with this adapter, and I could not fully insert it into any USB receptacle I have. Yes, I even turned it around all “three” ways, to no avail. Eventually I simply pulled out my own microSD adapter and it worked fine.

I then discovered that the provided version of Cura was not only old, but it was for Windows only — and I’m using a Mac. I decided to simply get the current version of Cura, which is now called Ultimaker Cura, by the way, directly from the source.

ANET did provide a Cura .INI file, which you can import into the current Ultimaker Cura software very easily. This provides basic print profiles for use.

A problem arose, however, as the Ultimaker Cura was unaware of the ANET ET4 machine — it was not among the 3D printers you can select in that version of the software.

But that’s not a problem, as you can simply specify the ET4 configuration in the appropriate preferences panel in Cura. But wait — I could not find this configuration information anywhere in the ANET ET4 package. I had to ask ANET for this data, which they provided immediately. I’m thinking ANET might want to consider including this information in their package.

If you happen to have Simplify3D, an excellent third party paid slicing software option, the process is much the same: configure the machine, and set up print profiles. However, I found it easier to use Cura.

Once a 3D model is sliced in Cura, you simply place it on the adapter-connected microSD card and then insert it into the ET4. And then reboot the ET4, remember?

ET4 3D Printing

![The ANET ET4 3D printing a standard GCODE file [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08efaa33ff.jpg) The ANET ET4 3D printing a standard GCODE file [Source: Fabbaloo]

The ANET ET4 3D printing a standard GCODE file [Source: Fabbaloo]

The ET4 has an unusual 3D print startup sequence. I’m always curious about these as they vary from machine to machine.

In the case of the ET4, the Z-axis is raised all the way to the top, presumably to hit the stop limit switch and thus understand exactly where it is on the Z-axis. This is perhaps because there is no other sensor system to detect the build plate, as you might have on other more expensive 3D printers.

While at the top, the X-axis carriage awaits heating, and finally glides gently down to the moving build plate to commence printing. Every print goes all the way up, then all the way down to start.

I found that 3D printing in PLA really requires a glue stick, as the heated glass plate doesn’t provide sufficient adhesion on its own. Glue sticks are cheap and quite effective, although you may have to re-apply it from time to time. For some reason, ANET did not include a glue stick in the package. The tempered glass plate can be removed for cleaning separately if required.

One challenge is that there is no display of the time remaining in a print. There is a progress bar, but that seems to reflect the number of GCODE instructions left, rather than the actual time remaining. The progress bar can move forward slowly at times, and rapidly at other times, depending on what’s in the GCODE.

ANET ET4 Surprises

I made an accidental, but very pleasant, discovery while 3D printing a small figurine.

The figurine was almost done, as only the top of the head was remaining. Suddenly, the lights went out in the lab.

Crap, I thought. Lost another print, and at the worst possible time, just before it completed.

Ten minutes later the power was restored and I walked over in the now-illuminated lab to see how to scrape off the print and start over. However, the ET4’s power switch was still “ON”, and it booted up by itself when power returned.

![The ANET ET4 offers to resume 3D printing after a power failure [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08efae5543.jpg) The ANET ET4 offers to resume 3D printing after a power failure [Source: Fabbaloo]

The ANET ET4 offers to resume 3D printing after a power failure [Source: Fabbaloo]

On the screen was a very welcome message: “Print Continue? YES / NO”.

YES? YES!!

I hit “YES”, of course.

![The ANET ET4 resuming this print after a power failure [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/et4-print-resume-after-powerfail-1_img_5eb08efb353e7.jpg) The ANET ET4 resuming this print after a power failure [Source: Fabbaloo]

The ANET ET4 resuming this print after a power failure [Source: Fabbaloo]

After a bit of warmup, the ET4 successfully resumed the print and it completed — while encountering a severe power failure. The ET4 has power recovery mode!

This is very surprising for such a low-cost device. Combined with the filament-out detector, you probably shouldn’t lose a print, ever, as long as you set up the bed adhesion properly.

ET4 Conclusion

![Our ANET ET4 prints the Stanley Cup successfully [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08efb88733.jpg) Our ANET ET4 prints the Stanley Cup successfully [Source: Fabbaloo]

Our ANET ET4 prints the Stanley Cup successfully [Source: Fabbaloo]

After using the ANET ET4 for a few weeks, I’ve found it to be a very solid machine.

It’s unbelievably quiet, seemingly quite reliable, and includes the safety measures described above. It includes a number of more advanced features you’d normally expect to see in higher priced units, making this device a bit of a steal.

My conclusion: I like this 3D printer. A lot.

The ANET ET4 is priced at US$249 on ANET’s web store. If you’d like to buy one, we’ve made arrangements for you to receive a discount of 10% if you use secret code “FABBALOO” at checkout.

Alternatively, if you’d prefer to purchase one on Amazon, we’d truly appreciate if you used our link to do so, right here. It won’t cost you anything and helps support this publication.

This is part 3 of a 3 part series:

Via ANET