![The new Desktop Metal Shop System for 3D printing metal objects at low cost [Source: Desktop Metal]](https://fabbaloo.com/wp-content/uploads/2020/05/ShopSystemPrinterandFurnace_img_5eb08d0a5ac93.jpg)

Desktop Metal announced an entirely new metal 3D printer today, the Shop System.

It’s actually more than just a 3D printer; it is an end-to-end metal 3D printing system that covers all aspects of the metal part-making process in an integrated manner.

The Shop System is targeted at a new client niche for Desktop Metal. Their previous Studio System was designed for office use, and intended for 3D printing of metal prototypes and very low volume production. Their Production system is designed for higher volume production of metal parts in a factory setting. Most recently they announced a continuous carbon fiber thermoplastic 3D printer, the Fiber.

Desktop Metal Shop System Specifications

![Sample metal 3D print from the Shop System showing very fine details [Source: Desktop Metal]](https://fabbaloo.com/wp-content/uploads/2020/05/ShopSystemRazorBlade_img_5eb08d0a9da75.jpg)

Unlike all of the above, the new Shop System is designed for “mid-volume runs of complex metal parts on the shop floor”. The device has four variants that correspond to the build envelope, with four capacities (4L, 8L, 12L and 16L). The smallest, 4L, has a build volume of 350 x 220 x 50 mm, while the 16L has a larger build volume of 350 x 220 x 200 mm.

I should point out that the build volume in the Shop System is not just about the ability to 3D print larger parts in one print job. No, it’s more about the ability to 3D print batches of smaller parts in one print job. Take a look at the 4L’s build volume and you’ll quickly realize what I mean

With a build volume height of only 50mm, you’d likely be either 3D printing a few flat and long parts, or a large batch of small parts spread over that area.

Most metal 3D printers are rather challenging to install in a workshop due to the environmental requirements of handling powder, meeting regulatory certifications, and post processing. However, the Shop System bundles all of these into its integrated hardware.

Shop System Binder Jetting

The 3D printing portion is done through a binder jetting process: a moving arm sweeps across a flat bed of fine metal powder, selectively depositing droplets of binder. Desktop Metal says the Shop System includes an astonishing 70,000 micro-nozzles, able to deposit 1.0pL (picoliter) droplets at 1600 dpi. That’s incredibly fine resolution, and this shows well on sample metal 3D prints.

![Very good detail and surface quality on this metal 3D print from the Shop System [Source: Desktop Metal]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08d0ae3750.jpg)

This approach is also very fast. Desktop Metal claims the Shop System can print objects at 10X the speed of typical powder bed / laser systems due to the droplet approach.

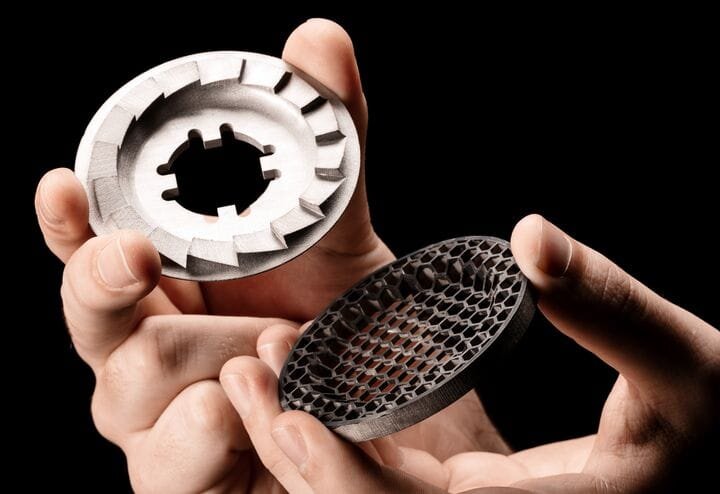

This method of deposition has another major advantage over standard powder bed / laser processes: elimination of support material. Normally, metal 3D prints are essentially welded to a thick metal build plate and must be sliced off with a Wire EDM machine. Even worse, any geometric support structures, which are also made from metal, must be carefully cut off, either manually or with a complex 5-axis CNC process. This creates the freedom for designers to easily 3D print highly complex metal geometries with far less risk.

None of this happens on the Desktop Metal Shop System because the part is always supported by surrounding metal powder. Thus the post processing steps are vastly simplified.

Shop System Post Processing

The 3D printing process is definitely not the end; there are more steps required to complete the 3D print. After 3D printing, you merely have a build chamber full of loose powder with a lightly-bound metal object buried inside. There are two steps left.

One is to de-powder the “green” print, and that’s done with an integrated depowdering station. In this step the loose powder is removed from the build chamber, presumably by vacuum and brushes. This must be done carefully as the green part is still rather fragile at this stage.

It’s not clear what happens to the removed residual powder, but I hope the Shop System will be able to reuse it in subsequently print jobs, which could substantially reduce the cost of materials. I’m intending on asking Desktop Metal how this works.

After the fragile green parts are successfully removed from the build chamber, they are placed in the accompanying furnace to remove the binder material and sinter the metal powder particles together to form a solid metal object. I suspect Desktop Metal has leveraged some of their expertise in developing the furnace for their Studio System here, so I expect this part of the process to work quite well.

Desktop Metal Shop System Throughput

Desktop Metal says the Shop System is able to produce “tens or hundreds” of parts per day, with batches completing every six to twelve hours depending on the part geometries. In all, they say the device has a maximum throughput of around 70kg of 3D printed metal per day, which is quite significant.

The company has priced the system at a level quite a bit lower than traditional powder bed / laser metal 3D printers, starting at only US$150K for the 4L variant, up to US$225K for the 16L variant.

[UPDATE] We’ve been informed by a Desktop Metal reseller that the price mentioned here includes the printer only, and that a turnkey solution including the necessary elements would be priced at approximately US$300K.

Note that this price includes the entire system, whereas powder bed / laser systems would also have to consider the costs of wire EDM machines, CNC equipment, powder handling gear, and environmental changes to the facility.

Desktop Metal Workshop Strategy

The Shop System seems designed to be literally “dropped into a workshop”, and I think that’s Desktop Metal’s strategy here. I’m not just talking about cost of the system or its integrated nature; Desktop Metal has also simplified the control software to make it very easy for operators to learn and use on a daily basis.

The costs of obtaining and operating powder bed / laser systems are so high their use is effectively limited to only high-price parts industries, such as healthcare and aerospace.

The Desktop Metal Shop System’s pricing should open up the usage to a much wider audience: metal workshops. Ask yourself this question: How many businesses are 3D printing metal aerospace parts in your city? And then ask: How many metal workshops are in your city?

Their strategy is very clear.

Via Desktop Metal