![Microscopic 3D print of Michelangelo’s David [Source: Exaddon]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08c49974bb.jpg)

I’m reading some reports on Exaddon’s CERES 3D printer, which was used to reproduce the famous Michelangelo statue of David, as seen above.

The catch here is that “David” is only 1mm tall.

I hadn’t heard of the Swiss Exaddon previously, but it turns out to be a spin off from Cytosurge. We wrote about Cytosurge’s development of a new microscopic 3D printing process in 2016, but it seems that the unit within Cytosurge that created the technology is now its own separate operation as of 2019.

![Exaddon’s CERES microscopic metal 3D printer [Source: Exaddon]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08c49d978a.jpg)

Over the course of several years, they’ve transformed the initial technology into a practical 3D printer product they call “CERES”, and describe it as follows:

“CERES is a stand-alone system that prints complex and pure metal objects at the micrometer scale, and with submicrometer resolution. Additionally, it writes patterns with liquids and nanoparticles that can be made of different materials.”

µAM 3D Printing

How, exactly do they do this? It seems they have developed a form of microscopic selective electroplating. They explain:

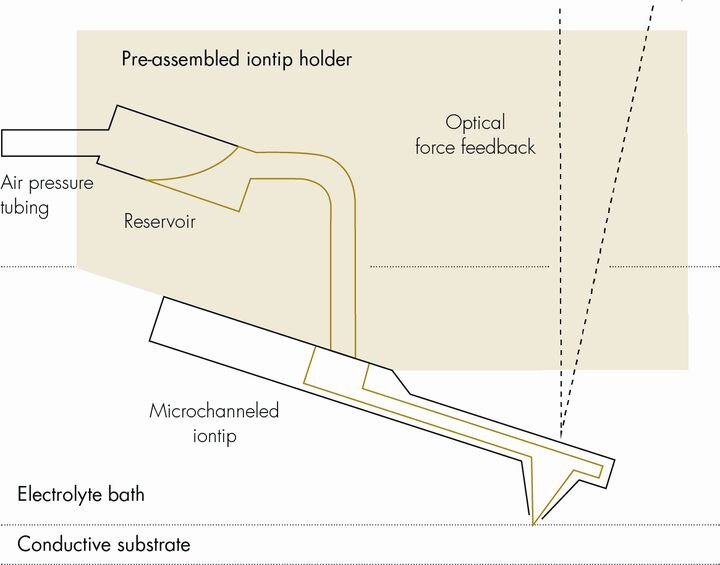

“A small printing nozzle, called an iontip, is immersed in a supporting electrolyte bath. A precisely regulated air-pressure pushes a liquid containing metal ions through a microchannel inside the iontip. The liquid flow is very small – as low as femtoliters per second. At the end of the microchannel, the ion containing liquid is released onto the print surface. The dissolved metal ions are then electrodeposited into solid metal atoms.”

Importantly, the process takes place at room temperature with no heat required. This simplifies the 3D printing process significantly, and is quite unlike almost all other metal 3D printing processes which require high energy or post-print sintering. The sole exception that I can recall would be Fabrisonic’s ultrasonic metal 3D printing process.

![Exaddon’s microscopic metal deposition tool head [Source: Exaddon]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08c4a23443.jpg)

Here you can see a video of the printing activity:

One very unusual aspect of Exaddon’s “µAM” process is that there seems to be a method of feedback during printing. They explain:

“The forces acting on the iontip can be measured optically, and are used as feedback. This allows the system to detect which voxels of the object have already been printed. This optical force feedback provides real-time process control.”

CERES Specifications

The µAM process can apparently 3D print overhangs to some degree, at least at a single voxel level. In addition, they say the process can handle a variety of metals, including gold, silver, copper, platinum and any others that can be electroplated.

The resolution of the CERES system is quite fine, ranging from 0.6 to 12 micrometers, and they say the machine can 3D print at up to 4 micrometers of material per second.

If you think about it, that’s pretty slow as 3D printers go. However, the objects being printed in the CERES machine are also quite small. The David statue shown above apparently took 12 hours to 3D print.

CERES Applications

While this is truly an amazing capability, there is likely limited use for the technology in niche applications. These would be applications requiring extremely small metal parts made from specific materials. Applications might include electronics, micro-machine components, or other new ventures we’ve not invented yet.

Via Exaddon