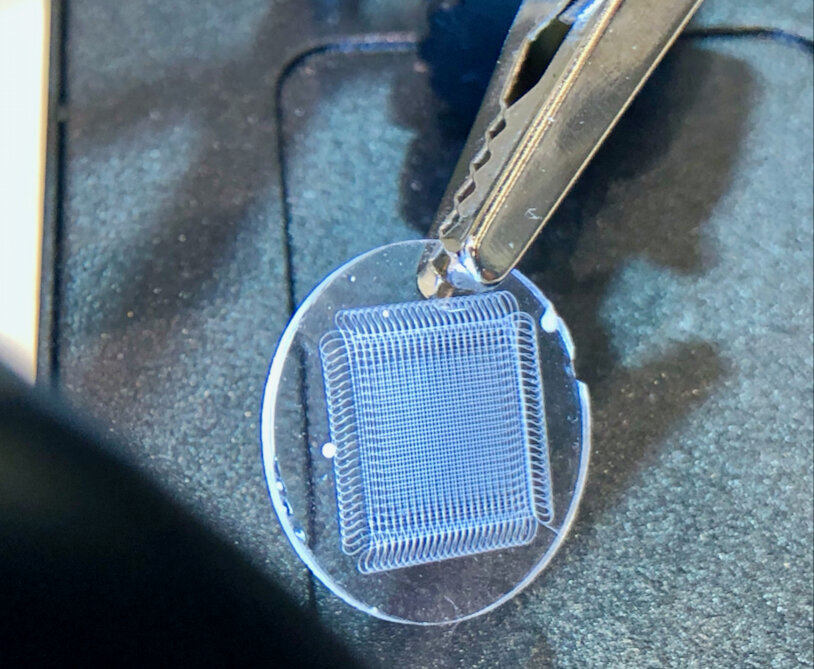

![An unbelievably tiny 100% glass 3D print made with Glassomer resin [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/glassomer-print-1_img_5eb08ce1151da.jpg)

We ran into a startup company that apparently has a way to 3D print transparent glass.

Glassomer is a German startup that began its existence in 2018. Their product is a liquid photopolymer resin that can be cured at room temperature to form solid glass, with some post processing.

The company does not intend on producing its own 3D printers, but instead wishes to merely produce the resin, which can apparently be used in any conventional resin 3D printer, either SLA or DLP. These processes involve selectively solidifying the photopolymer with a light source of suitable frequency, layer by layer to form a solid object.

Glassomer Resin

![Glassomer resin contains 60% glass particles [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/glassomer-resin-1_img_5eb08ce17b399.jpg)

Glassomer’s resin is one of the strangest I’ve seen. As you can see in this image, it appears to be a clear liquid with a slight tint. It appears fully liquid, with the consistency of very soft honey.

What you don’t see is the glass. This resin is surprisingly 60% glass! There are tiny glass particles mixed in with an organic binder and the glass particles are rather small, at 50-100nm in size. That’s “nanometers”, or 1000X smaller than a micrometer. A 50nm length is equal to 0.00005mm. That’s pretty small!

Glassomer Process

![The Glassomer 3D printing process [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/glassomerprocess_img_5eb08ce1f1266.jpg)

When 3D printed the resulting “green” object will appear white due to the porosity of the material. The post processing involves two steps.

The first step is to heat the green print to 600C, which burns out the organic binder, leaving only glass particles as a “brown” part.

The second and final step is to heat the brown print to 1300C to sinter the glass particles together. The result is a pure glass object with no porosity and completely transparent. The shrinkage rate through this process depends on the ratio of glass in the resin, but is typically around 15%.

Curing times depend on the thickness of the print, but can be done in around 3.5 hours.

But is the resulting object actually glass? They say:

“It IS glass.”

Glassomer Applications

![Applications of Glassomer’s glass resin [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/glassomer-optics-1_img_5eb08ce24079d.jpg)

While the steps above are shown with a plain rectangular object, it is entirely possible to 3D print very complex shapes with the material. Here we see one of the likely popular applications of the Glassomer resin, diffractive objects.

These diffractive lenses can be extremely fine. We were shown a demonstration by firing a green laser iteratively through a sequence of seemingly clear glass blocks. However, the green laser light bent into different patterns on each block, showing that the internal structures were unique.

At top you can see a ridiculously complex glass 3D print, where 100nm channels have been designed into the glass. I cannot imagine being able to produce this geometry in glass in any other 3D printing material and process.

The only other glass 3D printing processes I’ve seen involve heating glass material to an astounding 2000C and extruding fat lines of material with extremely limited applications. The Glassomer material changes the equation entirely and brings glass, as a regular material, into the hands of everyone using resin 3D printers. Well, at least if you happen to have a sintering furnace handy, too.

Glassomer says they can develop many formulations of the resin, depending on the application.

Glassomer Pricing

Can you use this amazing glass resin? Apparently, you can! It’s pricey, though, at €700 (US$770) per 500g.

Via Glassomer

1 comment

Comments are closed.