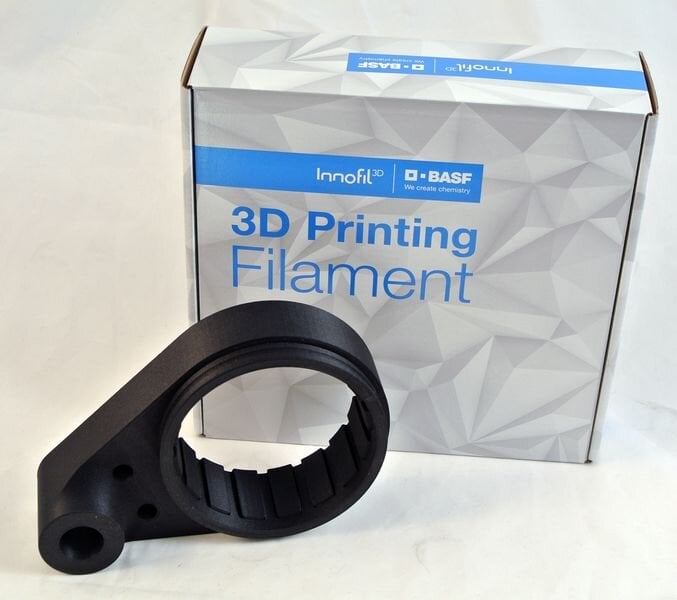

![You can now easily use certain third party 3D printer filaments on the Kodak Portrait 3D printer [Source: Smart International]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08bd3e6ee3.jpg)

Smart International announced a Materials Partnership Program to broaden the availability of engineering materials to the users of their Kodak Portrait 3D printer.

Smart International is an Argentina-based 3D printer manufacturer that has licensed the Kodak brand for use in 3D printers. Their initial product, the Kodak Portrait 3D printer, has been well received and is quite powerful. I’ve tested this device myself and found it to be quite reliable and extremely easy to use.

The Kodak Portrait device includes a number of high-end features, such as a closed environment for capturing heat, dual extruders (with one for low temperature & flexible materials, and the other all-metal extruder for high temperature materials), an easy to use control panel and a sophisticated cloud interface to slice, launch and monitor 3D prints. We reviewed the Kodak Portrait 3D printer here.

Kodak 3D Printer Open or Closed?

The funny thing about the Kodak Portrait 3D Printer is that it appears to be a closed materials machine, but it really isn’t. It uses acrylic canisters to hold the spools at the rear of the machine, and normally these would hold official Kodak filament spools. But there’s no major physical reason why you could not mount a non-Kodak spool.

One of the main reasons Kodak Portrait 3D printer operators stick with Kodak materials is that the slicing system for the device is in the cloud and has a library of highly tuned 3D print profiles for all of the Kodak materials, which by the way, are pretty extensive with nine different material types and many color options. If you want the best results in the easiest way, just use these materials.

Kodak Materials Partnership Program

But for some operators, other materials are required for their applications, and these materials aren’t in Kodak’s portfolio.

But now the new Materials Partnership Program has allowed Smart International to produce 3D print profiles for a number of third-party filaments that can now be used in the Kodak Portrait 3D printer as easily as any Kodak filament.

BASF DSM Clariant Filaments on Kodak

The initial offerings in the Materials Partnership Program include materials from BASF, DSM and Clariant:

-

BASF Ultrafuse ABS Fusion+

-

BASF Ultrafuse PAHT CF15

-

BASF Ultrafuse PA (first BASF Filament Development based on Ultramid)

-

BASF Ultrafuse Z PCTG (first official ESD safe filament

-

Clariant PA6/66-CF20

-

Clariant PA6/66-CF20

-

Clariant

-

DSM Novamid ID1030

-

DSM Novamid ID1030 CF10, (carbon fiber filled PA6/66 copolymer

-

DSM Arnitel ID2060 HT

These engineering-grade materials will be quite welcome to professionals using the Kodak Portrait 3D printer and could attract others who need the materials but previously passed by the Kodak Portrait 3D printer because of inaccessibility of the materials.

They haven’t told us, but it is very likely they are even now very busy developing 3D printing profiles for additional high-end materials. I expect to see similar announcements in the near future, as they add these new materials to the slicing system’s library.

Like other elements of the Kodak 3D Printer environment, this development makes it quite easy to use very powerful materials in the device. The Kodak Portrait 3D printer was already a terrific 3D printer, but the new Materials Partnership Program makes it even better.