If you are a user of Simplify3D, you want to read this.

Simplify3D is a third party 3D print slicing and print operation software tool. The theory is that the default software tools usually provided by the 3D printer manufacturer are sometimes incomplete in function. Simplify3D attempts to fill the gaps with more sophisticated functions and options.

While it’s a paid product (currently available for USD$149), its results are often better than those found with default tools and parameters. It can do some things rarely found in standard tools, potentially making printed parts stronger, for example. For some 3D printer operators, the extra cost of the tool is well worth the value.

Another benefit of using Simplify3D is that your tool becomes independent of the printer. In many cases you are tied to a particular tool per printer, but with Simplify3D you can at least attempt to use a single tool to operate many different types of 3D printers.

While Simplify3D offers a basic mode where you don’t have to twiddle many parameters, true users of Simplify3D will want to go deep into the countless printing parameters to tweak them towards print quality nirvana.

However, this can be extremely challenging as many parameters are not well understood in spite of the helpful hints that pop up when hovering above them in Simplify3D. Even less understood is the relationship between the parameters. Thus many users tend to experiment in order to find optimum results.

However, I found a fabulous resource for Simplify3D users (and any 3D printer operator, really). It’s a huge 76 page highly detailed analysis of Simplify3D printing parameters made by Clint Goss, Ph.D.

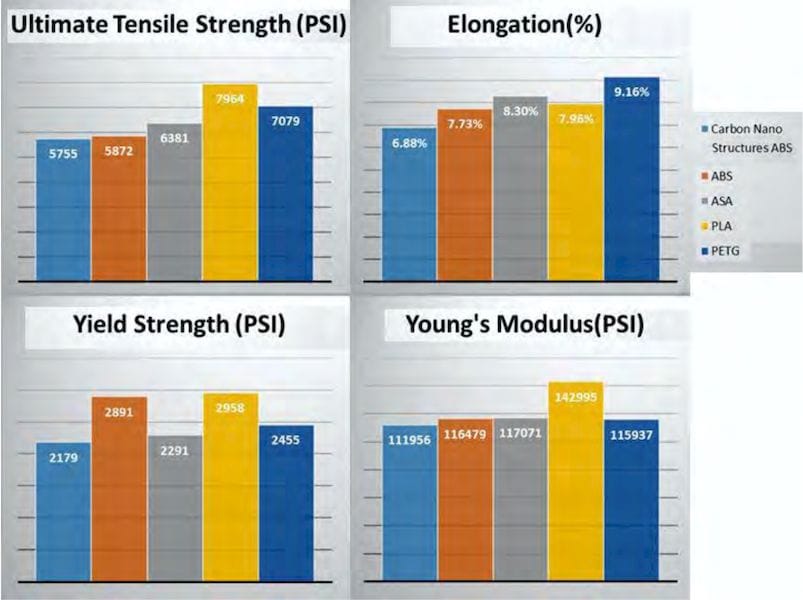

Goss is developing an unusual musical instrument, the “BreathFlute” using 3D printing. Evidently he’s designing the flute in OpenSCAD, where his design now encompasses an enormous 7,000 lines of code. But in order to obtain optimum results he’s been deeply investigating the use of Simplify3D. He explains:

This is my collection of information and documentation on the Simplify3D profile – the parameters and settings that control how Simplify3D (S3D) transforms the surface geometry of a 3D model (typically a .stl file) into the numerical control language used by most 3D printers (most typically a .gcode file).

I have collected this information from a wide range of sources. Organizing them into this single document has helped me to better control the complex transformations that S3D performs. However, this information is not authoritative nor an official voice of the authors of S3D.

What follows that introduction are many pages of detailed information about all aspects of 3D print slicing, all compiled into a proper sequence to understand all aspects of slicing for 3D printing.

Here we see an excerpt where he’s included a chart showing how the strength, cost, speed and quality of a part varies based on layer size and infill ratio. From this colorful chart you’d be able to more easily choose the right parameters for your particular project.

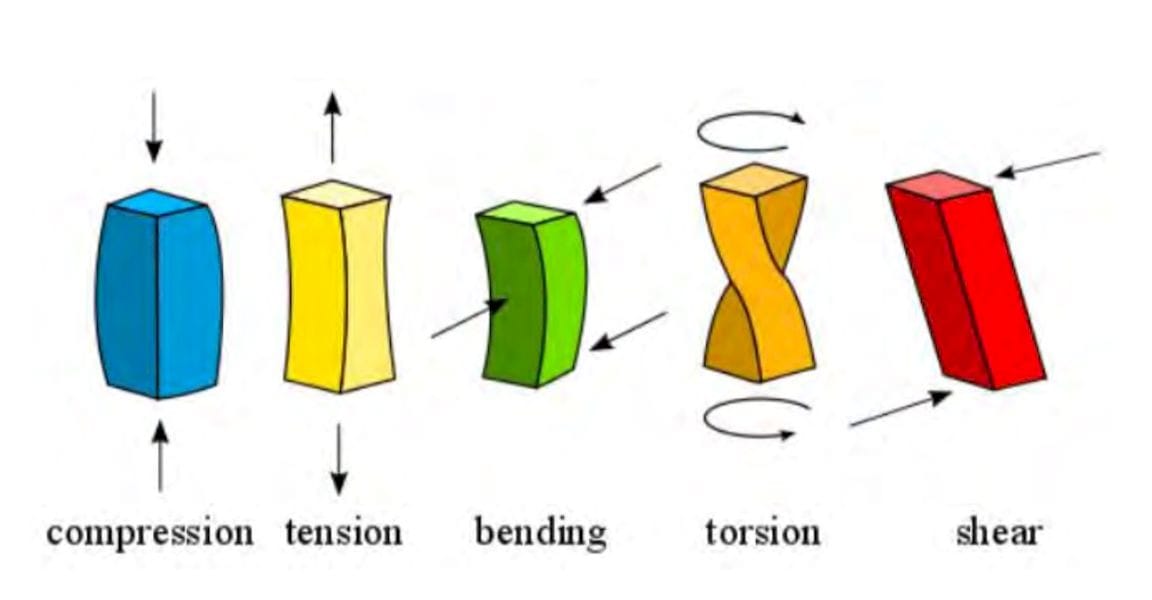

Don’t be overwhelmed by the size and detail level in this document; Goss goes to great lengths to explain many technical effects in plain language that anyone can understand. Here we see his graphical explanation of mechanical stress forces:

In many cases Goss will have found some documentation on a particular aspect of slicing and printing, and then he performs an experiment to verify the accuracy of the documentation, showing the results to the reader.

While the document is certainly skewed towards Simplify3D users, much of the material is entirely usable in other slicing tools, although you might have to develop your own parameter interpretation.

Goss has provided this resource to the 3D print community at no charge, and it’s available for download from his BreathFlute site.

If you’re a Simplify3D user, you definitely should check this out. In fact, check it out anyway even if you’re not.

Via BreathFlute (PDF) and Simplify3D