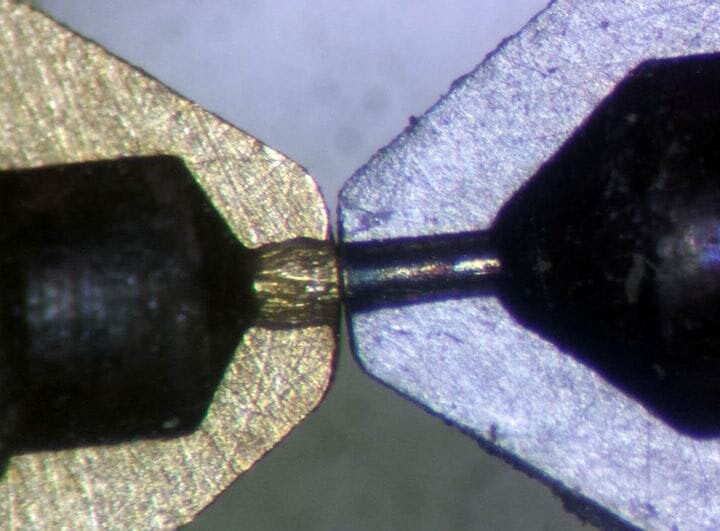

![Comparison of nozzle wear when using carbon fiber filament [Source: E3D-Online]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08df931ae1.jpg) Comparison of nozzle wear when using carbon fiber filament [Source: E3D-Online]

Comparison of nozzle wear when using carbon fiber filament [Source: E3D-Online]

How abrasive are the newer extra-strong filaments?

I don’t have a lot of experience (yet) with strong composite filaments for 3D printers, but they are becoming increasingly popular. That’s because many people are using them to create incredibly strong mechanical parts for end-use applications, rather than prototyping.

3D Printing Carbon Fiber Problems

The problem with these materials is that they tend to erode the nozzle’s shape and thus corrupt future 3D prints.

For example, if the nozzle’s diameter is increased through wear, then there will be more material coming out than is expected by the slicing software. This would result in a blobby and unattractive print, and there would likely be some stringing as well.

Another possibility is that the nozzle’s shape itself could be corrupted. While new nozzles fresh from manufacturing will have a perfectly circular exit hole, the abrasive wear might alter that shape to something other than round. Thus the nice clean beads you may normally see when extruding might not be so uniformly shaped, again leading to crappy prints.

3D Printer Nozzle Erosion

Why does this happen?

It’s because these strong filament materials are actually a mix of a standard polymer, like nylon or even PLA, with a very hard fiber: glass or carbon fiber. These fibers are essentially very short segments that flow along with the softened polymer. They remain quite solid, however, as their melting point is vastly larger than that of the polymers.

These fibers naturally crash into the sides of the extrusion path as the material flows, and that’s the source of the problem. The hot end in a 3D printer is typically made from brass, which is a relatively soft metal. The fibers — glass, carbon fiber or other strengthening substances — will be vastly harder than the soft brass.

This means that microscopic gouges are being made every second you extrude one of these materials. While one gouge might not be much of a problem, realize there will be a river of material flowing by with countless fibers interacting with the nozzle.

Avoid Nozzle Wear

The normal step for countering this is to replace the standard brass nozzle with something made from a harder material. Normally this is hardened or stainless steel, but I’ve also seen nozzles made from titanium or ruby.

My question was, exactly how long does it take to have a nozzle wear down. If just 3D printing a small amount of, say, carbon fiber filament, would it really affect the nozzle in any significant way?

I did some research and bumped into a four-year-old story from E3D-Online, makers of premium hot end and extrusion components used by many of the leading 3D printer manufacturers worldwide.

Their experimental results were quite shocking to me.

E3D’s Nozzle Experiment

They apparently used a brand new, stock brass nozzle and printed only 250g of standard carbon fiber filament on it. Then they cut it open and examined it with a microscope. The image at top is what they observed. They say:

”The tip of the nozzle has worn significantly, being worn down making the nozzle shorter in overall length. The tip of the nozzle has also been rounded over into a dome shape due to abrasion. Most surprising was the level of wear on the inside of the nozzle orifice which has been significantly opened up in diameter and has worn in an ugly uneven fashion.

The wear on the inside of the nozzle orifice causes the nozzle to taper out in diameter. Furthermore, for some inexplicable reason the wear is greatest in the middle, causing an ovoid type wear cavity in the nozzle orifice.

As a control we took the nozzle that was previously on the machine, which had printed many many kilos of standard materials with no abrasive fillers over the course of a few months, and cross sectioned it for the microscope too.

There was no observable wear at all on the nozzle that had printed only standard materials.”

In the top image, the nozzle on the left printed the 250g of carbon fiber filament, and the nozzle on the right is a hardened steel nozzle that had apparently 3D printed 2.5kg of carbon fiber materials. There is clearly a difference here.

Instant 3D Printer Nozzle Damage

![Comparison of nozzle wear when using carbon fiber filament [Source: E3D-Online]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08df959aa7.jpg) Comparison of nozzle wear when using carbon fiber filament [Source: E3D-Online]

Comparison of nozzle wear when using carbon fiber filament [Source: E3D-Online]

The most surprising thing to me is that this massive amount of damage to the brass nozzle occurred with only 250g of carbon fiber material. That’s only 1/4 of a standard 1kg spool! Imagine what the nozzle would look like after an entire spool was 3D printed.

The bottom line here is a caution: if you intend on 3D printing in carbon fiber filament, or other hardened composite material, you must use a hardened nozzle. You cannot 3D print this stuff even once on a brass nozzle.

Via E3D-Online