Dyndrite announced a new integration that allows for 3D printing of metal parts with controlled porosity.

Dendrite is a powerful software solution that leverages GPU technology to rapidly prepare highly complex 3D print jobs for industry. The software handles a variety of typical 3D print processes, including jetting, photopolymerization, and LBPF.

Dyndrite has partnered with Elementum, an advanced metal powder provider, on this project. Elementum supplies several materials, including aluminum, nickel, copper, steel, tantalum, tungsten, and even custom powders.

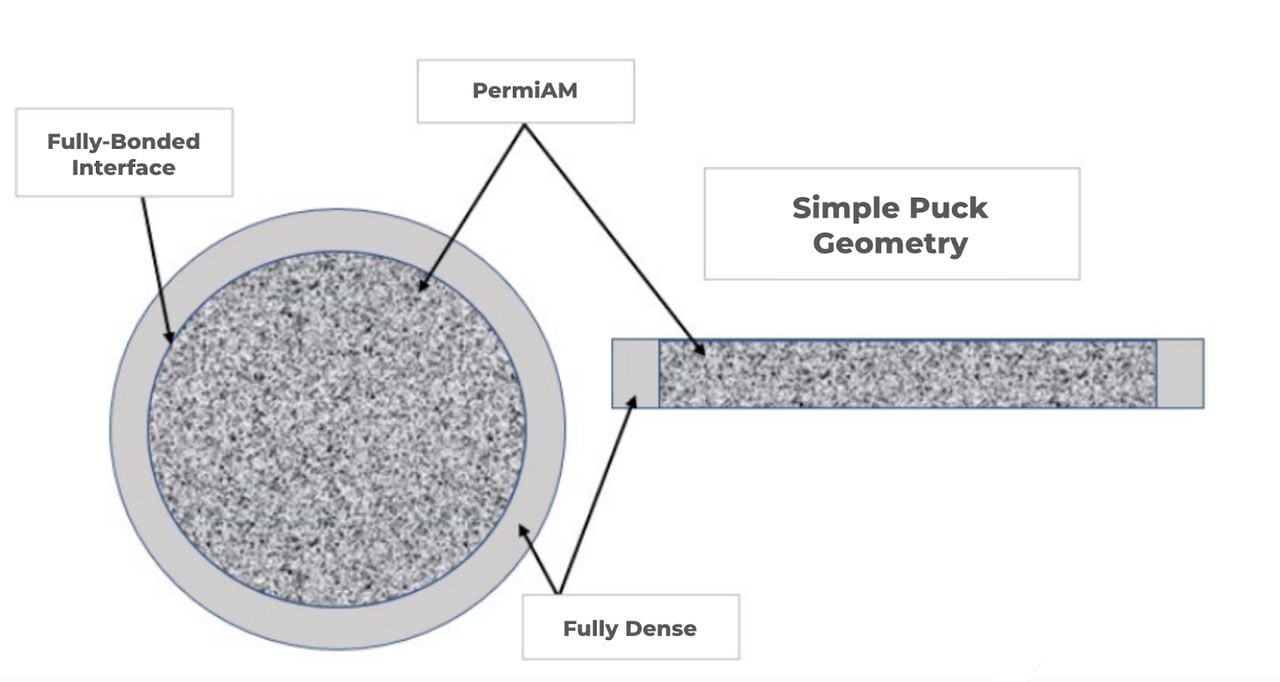

While Elementum normally supplies material, this project deals with how the material is handled by LBPF 3D printers. The integration is with PermiAM, a new software tool developed by Elementum and Astrobotic. PermiAM is explained by Elementum:

“PermiAM, developed by Elementum 3D and Astrobotic, and soon accessible through Dyndrite’s LPBF Pro software, enables LPBF engineers to 3D print to different parameter strategies within different volumes of the same part to allow for precise coolant flow, while maintaining structural integrity.”

This is quite interesting because it should allow engineers to design and produce parts with porous regions that could allow for fluid flow. Elementum believes the technology could be of great use in the aerospace industry, specifically for hypersonic applications, rocket engines, or other propulsion systems involving fluid flow.

Does this technology actually work? Apparently so, as the companies performed a hot fire test of a sample metal 3D printed part that used PermiAM. They explain:

“Masten Space Systems [now Astrobotic] and Elementum 3D have completed successful hot fire testing of their jointly developed new PermiAM 3D-printed fuel injector to capstone the NASA Phase I SBIR project. The PermiAM technology enables design simplification and cost savings by combining regions of controlled permeability with fully dense structures within the same injector component. The technology could also be applied to other applications, including commercial jet engines or automotive fuel injection. Additional development work is ongoing for A1000-RAM10, GRCop-42, and Inconel 625 materials through a NASA Phase II SBIR program.”

PermiAM is certainly a very powerful tool that should open up a range of new metal 3D-printed applications in several industries. The integration with Dyndrite should make it even easier to access and make Dyndrite itself more interesting for 3D printer operators.

Via Dyndrite