New research has identified a way to more properly send electrical signals through 3D printed material.

Conductive polymer composites (CPCs) for FFF 3D printing are not new; they’ve been around for at least a decade. The concept is to mix conductive material with a polymer to provide an electrical path along an extrusion. This could be used to, for example, print signal or power “cables” directly into a part. It’s also possible to introduce heat into the part through these materials.

The study investigated the behaviour of CPCs in a range of situations to determine the optimal methods for their use.

The researchers found that the conductivity is governed by the distribution of conductive fillers in the material, and the presence of voids formed while performing FFF 3D printing. They also found that printing parameters, such as filament adhesion, void distribution, and layer orientation, significantly impact the electrical and mechanical properties.

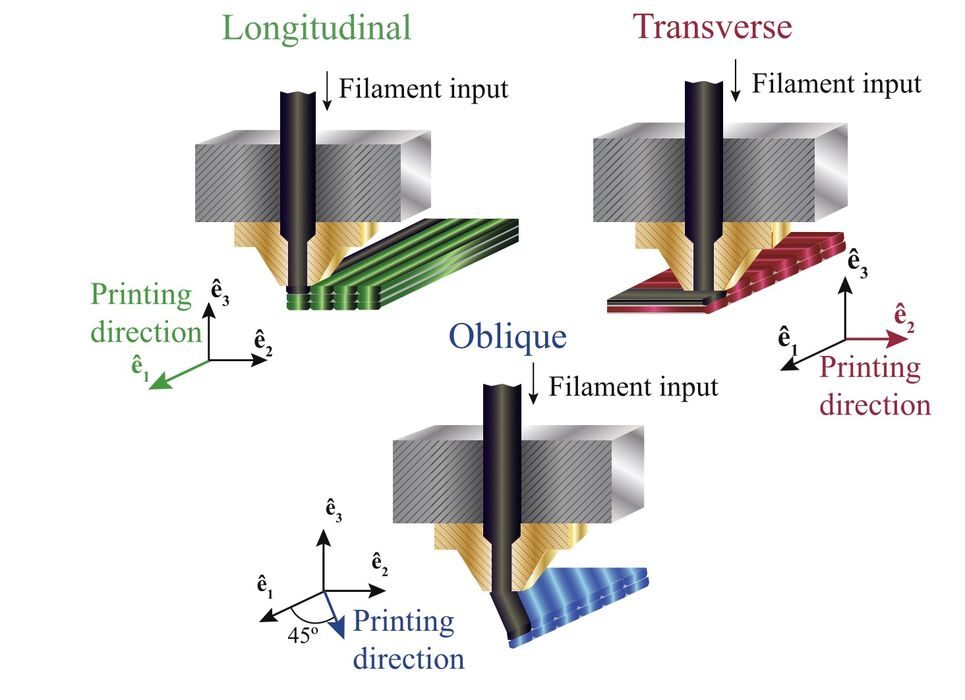

For example, orientation significantly affects electrical properties:

- Longitudinal orientation: Lower resistivity due to conductive paths aligning with the current flow

- Transverse orientation: Higher resistivity due to more voids interrupting electrical pathways

- Oblique orientation: Intermediate resistivity; partially optimized electrical pathways

The researchers developed a system to model these effects to provide a way to more easily design effective electrical and thermal properties in 3D printed parts. The model looked at both small-scale and large-scale aspects.

Their study bridged the gap between mesoscopic (small-scale) material characteristics and macroscopic (large-scale) device behavior. By using both homogenization techniques and continuum modeling, the researchers can predict how printing parameters influence overall performance, allowing for optimized design before fabrication.

With their system, it should be more feasible to design effective CPC applications, including:

- Customizable 3D printed sensors and electronics

- Heatable 3D-printed components for medical or industrial applications

- Optimization of functional materials for smart textiles, robotics, and aerospace components

This technology could prove quite valuable for future electrical part applications.

Via Nature