It seems that Piocreat is about to release a “pelletizer”.

If you’re not familiar with Piocreat, they are a 3D printer manufacturer associated with Creality. They produce a different line of 3D printers, specifically for industrial markets. The two areas they service are the dental market and pellet 3D printing.

At the top you can see one of their pellet devices, the G5Ultra. This might appear in the image as a typical desktop open-gantry device, but in fact it is quite large. The build volume on this machine is a whopping 500 x 500 x 400 mm.

You can see the hopper on the top, and the feed tube that takes pellets down to the extruder and hot end. The device is sold for several thousand dollars, and is typically used for industrial purposes.

The G5Ultra is Piocreat’s smallest 3D printer, as they offer larger machines with 1200 x 1000 x 1000 and an enormous 3725 x 2500 x 1330 mm. While the G5Ultra is large, it is a desktop machine.

The ability to print in pellets is the most interesting feature, because pellets can be as much as 10X less expensive than filaments. That’s of great interest to anyone printing large objects, which is what you do with these huge 3D printers.

Pellets are inexpensive, but do you know what might be even less expensive? It’s all those print scraps you’ve been collecting. That would include failed prints, early versions, support structures and bits of cut-off filament. Every 3D printer operator has a small mountain of that stuff.

You can’t use that material in your pellet device, however, because it’s the wrong size. That material has to be chopped up into bits of a maximum size that fits the pellet feeder.

Unfortunately Piocreat does not market a machine to do this, so you’re limited to buying fresh pellets.

But hold on, there is a rumour they may be soon offering a “Pelletizer” device.

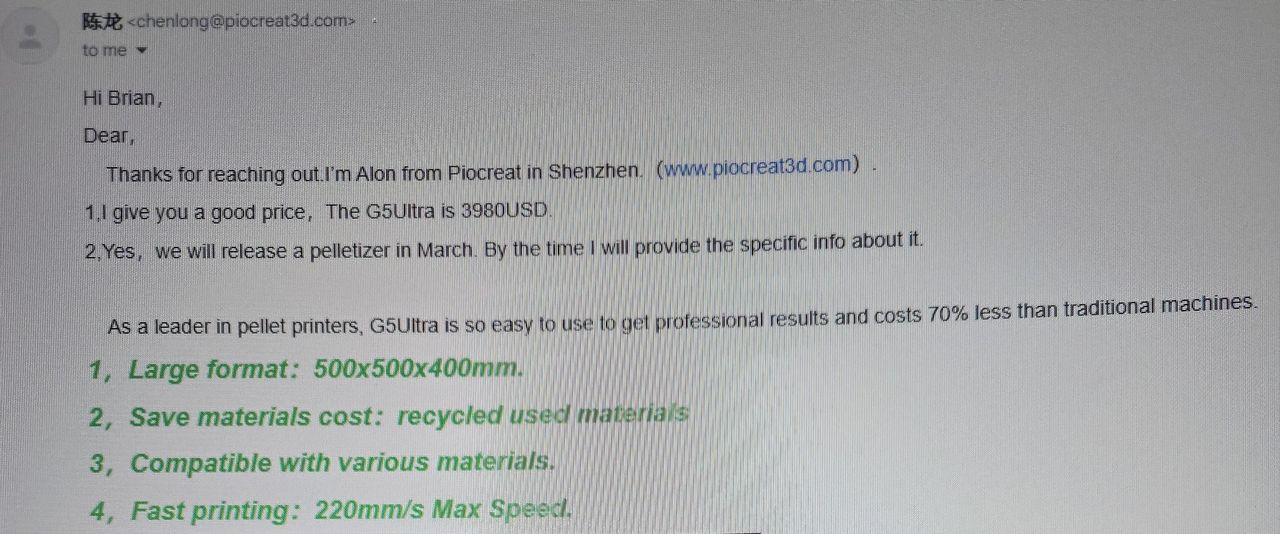

In a curious post on Reddit, contributor Seraphin posts the text of an email between them and Piocreat representatives. Seraphin is seeking a way to print recycled plastic, and pellet machines are a good place to start the search.

The interesting part is in the text of the email, where it’s written:

“Yes, we will release a pelletizer in March.”

If that is true, then G5Ultra operators would presumably be able to toss in 3D print scraps into the pelletizer, which would convert it all into bits of appropriate size for the pellet feeder. The leftover plastic could be directly reused for new prints.

That’s good news, but that’s all we know about it. We don’t know the date, price, or anything else about this pelletizer. Nevertheless, it would certainly be a mandatory accessory for G5Ultra operators.

Ironically, the Reddit discussion revolves around whether the machine itself is a scam. It most definitely is not. I’ve seen this machine myself multiple times and have seen it printing quality objects. The reason for the confusion is that Piocreat is addressing a different market, and the general public hasn’t seen much of this machine or company.

As for the price of the G5Ultra, it is a bit pricey compared to a standard desktop 3D printer. However, it can print very large objects, far larger than almost any desktop device. The use of pellets should also be factored into the cost equation. For example, if you intend on printing ten 1kg spools of filament per month at US$20 each, that’s US$200 per month, or US$2400 per year. With pellets, that material cost could be only US$240ish, saving over US$2000 — in a single year.

Depending on the amount of 3D printing being done, the G5Ultra might even be less expensive to use than a filament 3D printer.