Who is the real UltiMaker? I visited their HQ to find out.

UltiMaker is one of the more well-known companies in the 3D print space, being the product of a merger between Ultimaker and MakerBot, both pioneers in the world of desktop 3D printing. While their company name seems to be most related to the original Ultimaker, it’s really “Ulti” + “Maker”, showing the dual company heritage.

For many years, both companies pursued the generic desktop 3D print market. They produced low-cost FFF devices of a general-purpose nature, hoping to attract DIY folks. Both companies did so, gaining significant reputation in the process, particularly with the open-source community.

However, their open-source approach allowed others to directly compete with lower-cost equipment, taking away a huge share of their market. These competitive pressures pushed both companies to move away from their original open-source approaches to survive and ultimately merge together.

The shift away from open-source generated a ton of bad press online, particularly in MakerBot’s case. To this day, you will still see individuals posting negative material about the company, even though it really doesn’t exist anymore.

Today’s UltiMaker is quite different. They no longer make products for the generic, low-cost 3D printer market and haven’t done so for quite a while. Instead, they are implementing a two-pronged strategy for success.

To learn more, I journeyed to their Americas headquarters, located on the tip of Manhattan on the 51st floor, where on a good day, you can look out into the harbor and see the Statue of Liberty.

Prong One: Education

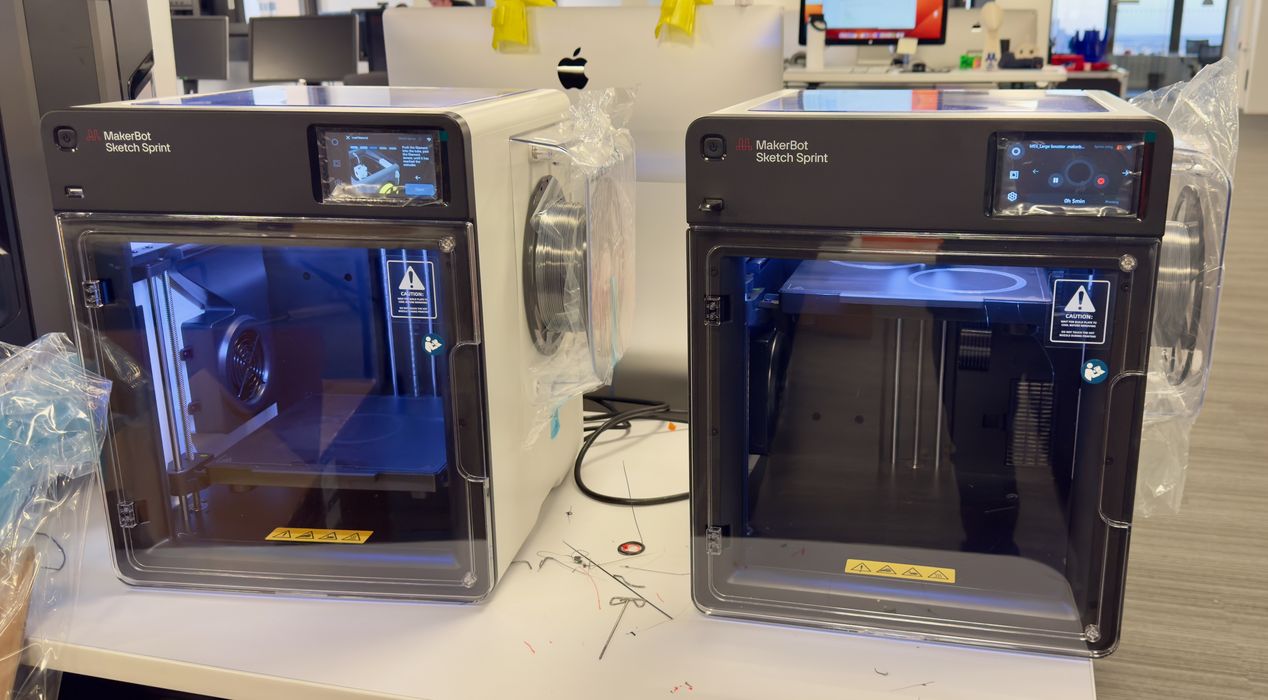

MakerBot always had a strong presence in the education market, particularly at the beginning when they were one of the few options available. Nowadays, they’ve completely transformed their product for education, with their latest platform, the MakerBot Sketch Sprint.

This is a high-speed desktop 3D printer using an advanced CoreXY design. Ultimaker’s President, Americas, Jim Franz, told us that it’s even faster than a Bambu Lab X1C.

The device is also equipped with a variety of safety features that are highly suitable for use with children in a schoolroom setting, including probably more certifications than most desktop 3D printers.

But that’s really not the story. The story is that the Sprint comes with a massive educational package of lessons, 3D models, and other educational artifacts. An educator making a decision about a purchase will know that if they buy a Sprint, they automatically get all the items their teachers will need to properly use the device in the classroom.

That’s something most other desktop 3D printers don’t offer. For the educator, the choice is less about features of the printer and more about the ability to use it properly in an educational setting.

Prong Two: Factory

The successor to the Ultimaker line of 3D printers today is the Factor 4, an industrial 3D printer.

The system is fully instrumented and has a rather large build volume. It uses a six-spool switching unit below the printer for multimaterial 3D printing, or simply for additional material capacity. While the Factor 4 still uses the rapidly fading 2.85mm filament standard, Franz suggested they may be moving to 1.75mm filament at some point.

Clearly, the US$20,000 Factor 4 is not for hobby use, but who is it intended for? Ultimaker explained that they are targeting factories and locations requiring 3D print capabilities.

For example, they have customers using the Factor 4 on oil rigs, where spare parts can be printed using the device. The Factor 4’s ability to reliably produce quality parts in suitable materials makes this quite possible.

Another application would be in a factory where jigs and fixtures must be printed to keep the line moving as efficiently as possible. This is, in fact, where the name of the product originates: if you say “Factor 4” quickly, it almost sounds like “Factory Floor”.

The New UltiMaker

Today’s UltiMaker is not at all like its predecessor companies. Today, they are focused on applications, not boxes. Franz explained that they no longer look for “transactional sales” anymore. They work very closely with resellers and have to qualify them extensively before they are allowed to sell equipment to their customers.

The markets addressed by UltiMaker are most definitely not the same as those served by Bambu Lab, Creality, Prusa, and similar companies. While MakerBot and Ultimaker might have appeared on that list years ago, they definitely don’t belong there now.

The next time you see a criticism of UltiMaker, remember that they are selling to a completely different market that has nothing to do with generic desktop 3D printing.

Via UltiMaker