Charles R. Goulding and Preeti Sulibhavi examine how Zimmer Biomet’s US$1.1 billion acquisition of Paragon 28 strengthens its 3D printing capabilities, revolutionizing personalized orthopedic solutions.

On January 28, 2025, Zimmer Biomet Holdings, Inc., a global leader in musculoskeletal healthcare, announced a definitive agreement to acquire Paragon 28, Inc., a company specializing in foot and ankle surgical implants and equipment, for approximately US$1.1 billion. This strategic move aims to enhance Zimmer Biomet’s orthopedic surgical devices portfolio, particularly in the foot and ankle segment.

Zimmer Biomet, headquartered in Warsaw, Indiana, operates in the medical device or medtech industry, focusing on designing, manufacturing, and marketing orthopedic reconstructive products, including knee, hip, and shoulder implants, as well as products for sports medicine, biologics, extremities, and trauma surgeries. As of 2024, Zimmer Biomet reported sales of US$7.8 billion and employed approximately 18,000 individuals worldwide.

Paragon 28, based in Englewood, Colorado, is dedicated to developing innovative solutions for foot and ankle surgeries. The company’s product portfolio includes plates, screws, staples, and biologics designed to address various foot and ankle pathologies. In 2024, Paragon 28 reported sales of US$200 million and had a workforce of around 500 employees.

Enhancing 3D Printing Capabilities

The acquisition is expected to significantly bolster Zimmer Biomet’s 3D printing initiatives. Paragon 28 has been at the forefront of integrating 3D printing technology into its product development, offering patient-specific solutions that improve surgical outcomes.

By incorporating Paragon 28’s expertise, Zimmer Biomet can expand its 3D printing capabilities across a broader range of orthopedic applications. This integration will likely lead to the development of more personalized and anatomically precise implants, enhancing patient outcomes and broadening the scope of treatable conditions.

Paragon 28’s 3D Printed Products

Paragon 28 has developed several notable products utilizing 3D printing technology:

- Patient Specific Talus Spacer: This implant is designed for patients with avascular necrosis of the talus, a condition leading to the death of bone tissue due to lack of blood supply. The 3D printed spacer replaces the damaged talus bone, preserving joint motion and offering an alternative to fusion or amputation.

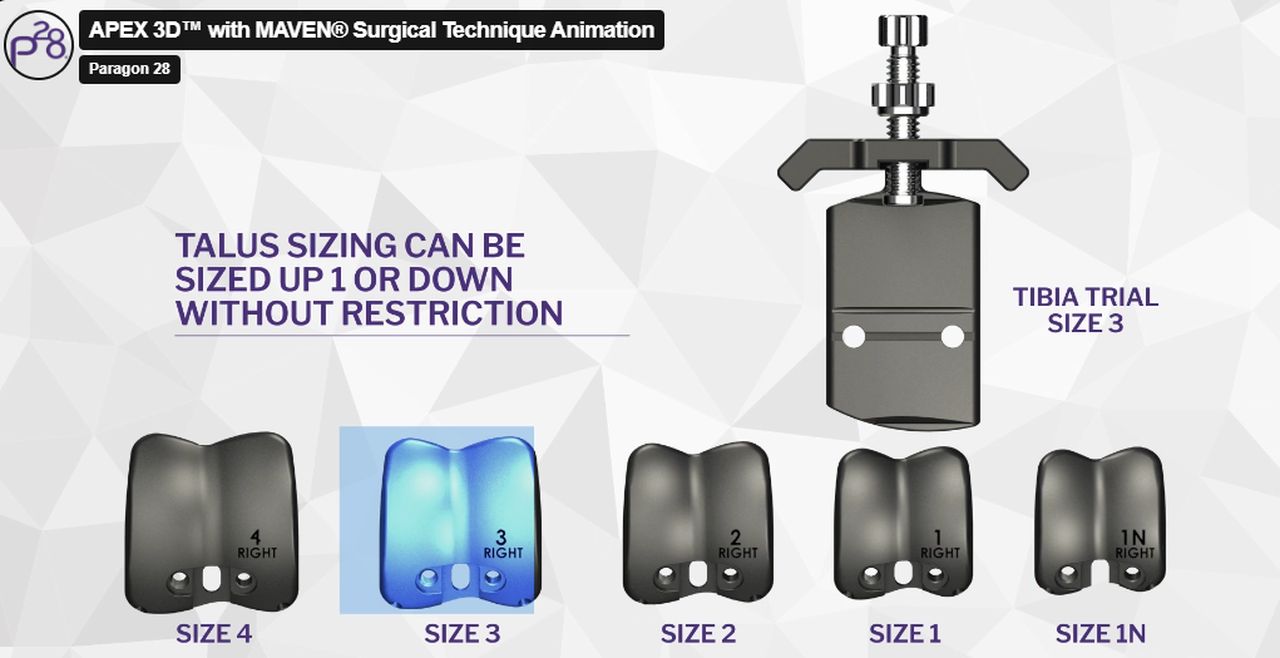

- APEX 3D™ Total Ankle Replacement System: Developed to address end-stage ankle arthritis, this system features anatomically contoured implant components produced through 3D printing. The design aims to reduce pain and restore natural motion by closely mimicking the patient’s anatomy.

- Patient-Specific 3D Printed Implants: Leveraging advanced 3D metal printing technology, Paragon 28 offers patient-specific implants for complex reconstructions, limb salvage, and implant revisions. These customized solutions are designed to meet the unique anatomical needs of individual patients, enhancing surgical outcomes.

- Additive Orthopedics Product Line: In 2021, Paragon 28 acquired the assets of Additive Orthopedics, a company specializing in 3D printed implants. This acquisition expanded Paragon 28’s portfolio to include innovative solutions for foot and ankle surgeries, such as patient-specific implants and instruments.

Synergies and Future Prospects

The integration of Paragon 28’s advanced 3D printing technologies into Zimmer Biomet’s extensive distribution network and resources is poised to accelerate the development of next-generation orthopedic solutions. This synergy will likely result in:

- Expanded Product Offerings: Combining expertise will enable the development of a wider range of patient-specific implants across various orthopedic disciplines.

- Improved Patient Outcomes: Customized implants designed through 3D printing can lead to better anatomical fit, reduced surgery times, and faster recovery periods.

- Increased Market Share: The acquisition positions Zimmer Biomet to capture a larger share of the growing market for personalized orthopedic solutions.

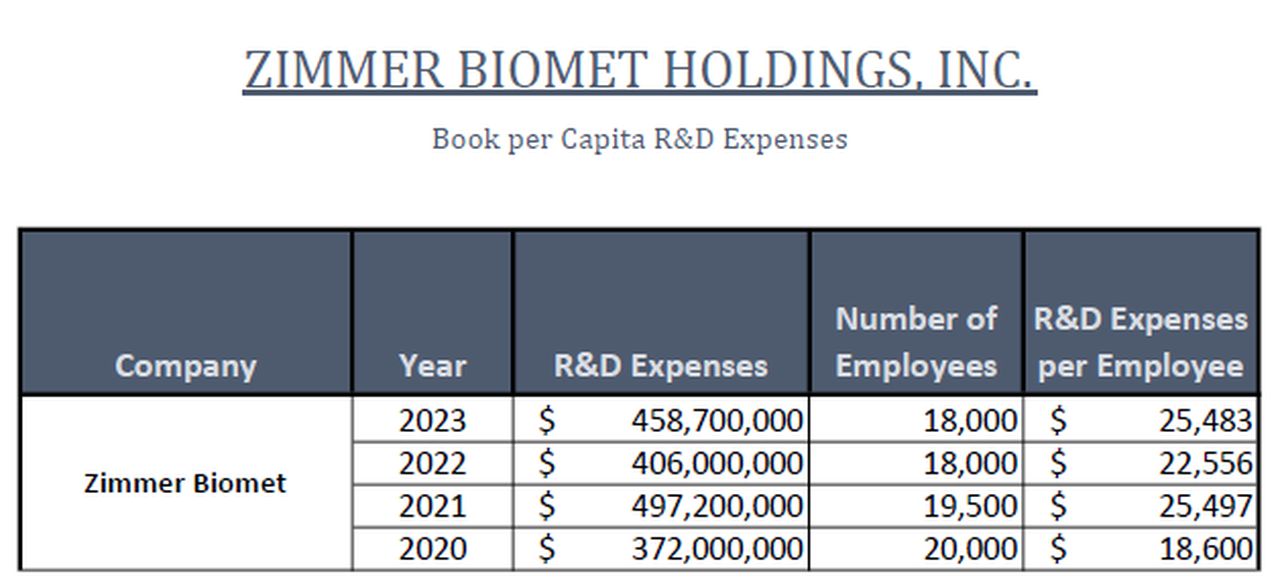

Below is a table that represents the investments Zimmer Biomet has made in research and development over the past few years.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes are typically eligible expenses toward the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software can also be an eligible R&D expense. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Zimmer Biomet’s acquisition of Paragon 28 represents a strategic alignment that leverages both companies’ strengths. The enhanced focus on 3D printing and patient-specific medtech solutions is anticipated to drive innovation in orthopedic care, offering improved outcomes for patients worldwide.