I had a look at Zongheng3D’s unusual top-down SLA 3D printer.

The company, based in Southern China, markets quite a range of industrial 3D printers. Currently, they have eleven different products available, covering SLA, SLS, and DLP 3D printing processes.

The machine we’re looking at today is the Super Maker DM200, one of the smaller machines from the company. It’s a resin system, but one with a very unusual approach: it’s a top-down design.

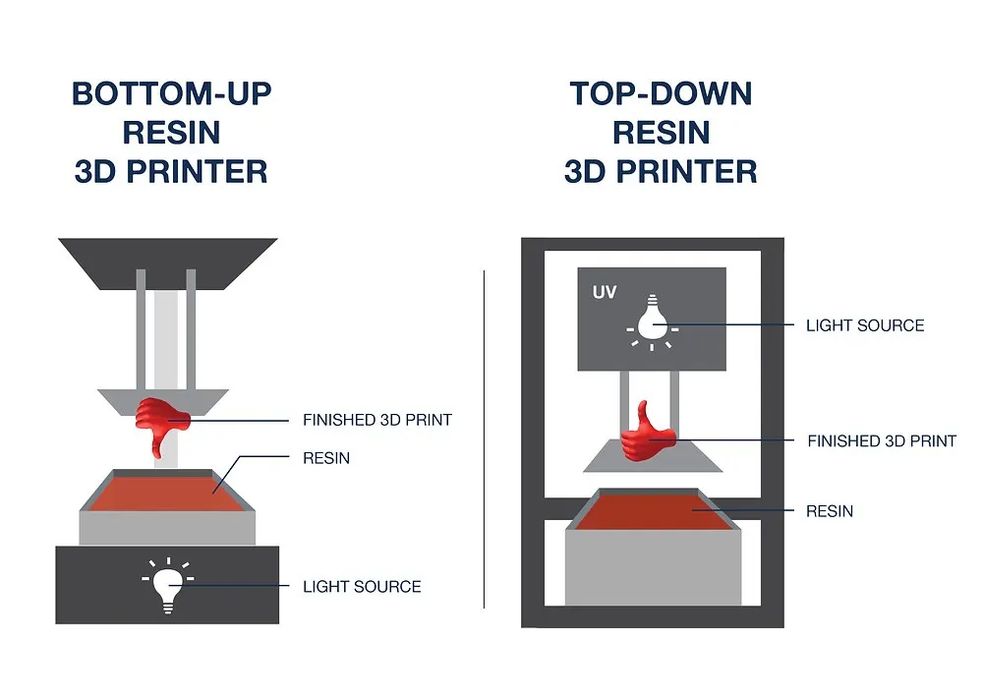

This differs considerably from the standard bottom-up designs we see from Formlabs, Creality, Anycubic, and many other companies. In a bottom-up system, the light energy is sourced from below and travels through a transparent tank bottom to reach the resin. The bottom of the tank is, by definition, flat, ensuring each layer is also flat.

A top-down system is much simpler and, it turns out, faster. Light energy is sourced from above and shines on the flat surface of the liquid resin. This simplifies the process quite a bit, as there is no need to peel fresh layers off a tank bottom.

However, it also requires that the device be perfectly level; otherwise, the resin will be at an angle. You also cannot disturb the machine while printing, or the resin surface may be distorted.

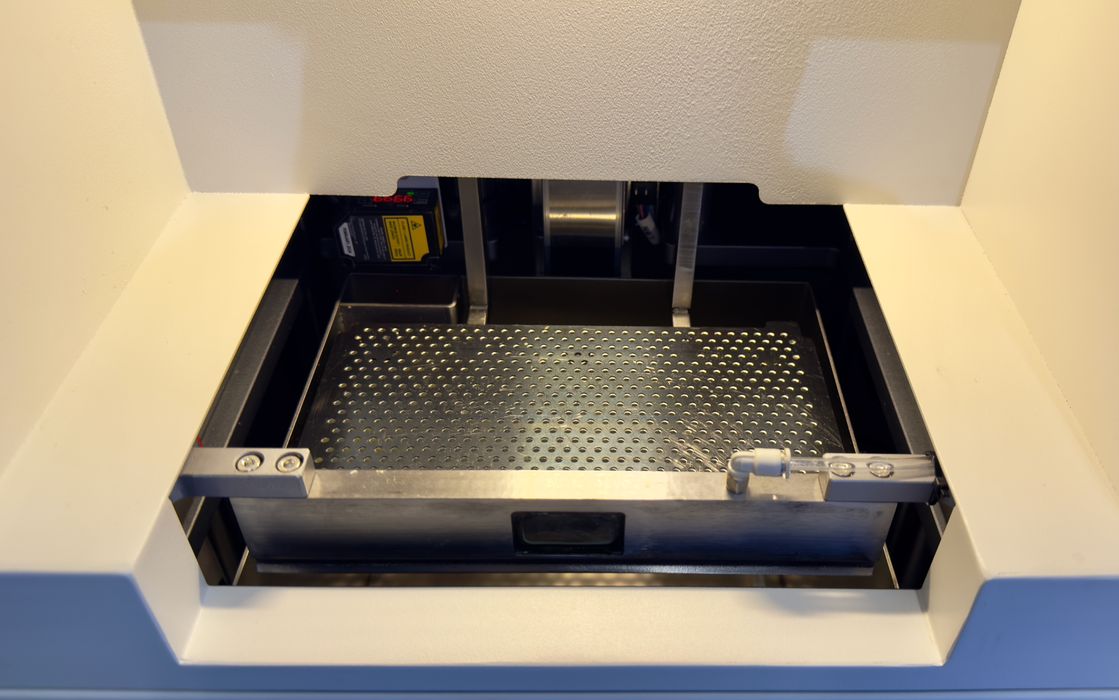

Here we see the build chamber, which is basically a platform that slowly lowers during printing. The resin flows over the top of the plate, and each layer is built on top of the prior structure. A swing arm slides across at each layer change to ensure the printed structure has a bit of liquid resin on its top surface.

When the job completes, the print is submerged in resin, and the platform rises up for removal.

There are a number of advantages to this approach, including faster printing. There’s also no tank film to puncture or replace. The light doesn’t have to travel through a film, so it carries more energy when it hits the resin, which can lead to greater print consistency.

The build volume on the DM200 is 192 x 108 x 120 mm, typical for a fine-detail small resin 3D printer. A 4K DLP projector provides the light source for printing. Print speed is listed at 6-8 seconds per layer, so in an hour the machine could print between 6-8 cm.

Top-down 3D printing is an underrated technology in our industry, and there are few companies producing equipment using that process.

Zongheng3D is one of them.

Via Zongheng3D