CFSYS is a new Shanghai-based company that produces a continuous carbon fiber 3D printer.

Continuous carbon fiber differs from the “carbon fiber filaments” you see on the market. Those are simply polymer mixed with chopped carbon fiber segments. Yes, it makes the material stronger, but it’s far less strong than using actual lengths of carbon fiber.

That’s what CFSYS’ Alpha 450 3D printer does: it prints polymer and lays down long strands of carbon fiber into the prints, layer by layer.

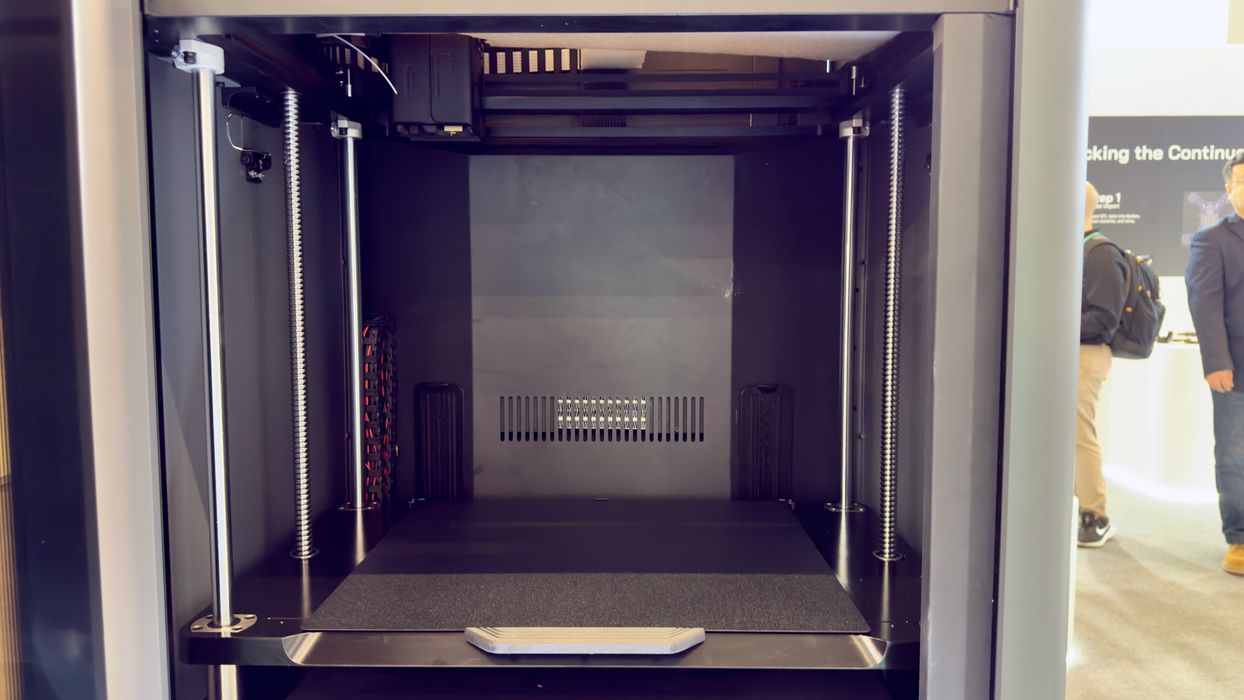

We had a brief look at their new machine, the Alpha 450, recently. It’s a desktop-sized device, but has an optional stand underneath for materials storage and processing.

The Alpha 450 is a professional 3D printer that the company describes as “next generation”. It offers high-speed printing, up to 600mm/s, and has an actively heated enclosed build chamber that can reach 70C. This enables printing of more advanced engineering materials.

The machine can be equipped with dual extruders, and one of them can be for continuous carbon fiber. Above you can see how this works, with one PTFE tube feeding polymer filament, and the other feeding carbon fiber.

At the bottom of the machine in the accompanying stand, there is space for several spools of material, including carbon fiber. The storage area doubles as a filament dryer, able to be heated up to 120C to ensure filament is properly conditioned before printing.

CFSYS joins the very small group of companies that produces continuous carbon fiber 3D printers.

In addition to the Alpha 450, the company also markets a smaller version, the PicaNets 120.

Via CFSYS