Flashforge has entered the multicolor desktop 3D printer game with the introduction of their new AD5X device.

Flashforge is one of the oldest manufacturers of desktop 3D printing, and it’s good to see they are keeping up with the latest trends. Since Bambu Lab introduced their AMS solution two years ago, most of the major desktop FFF 3D printer manufacturers have had to follow along. Now it’s Flashforge’s turn.

The new AD5X builds on the company’s well-regarded Adventurer line. They are enclosed 3D printers, and we reviewed the Adventurer 4 Pro last year. We found that machine to be quite capable and able to print a wide range of materials easily. Those qualities are likely found in the new AD5X as well.

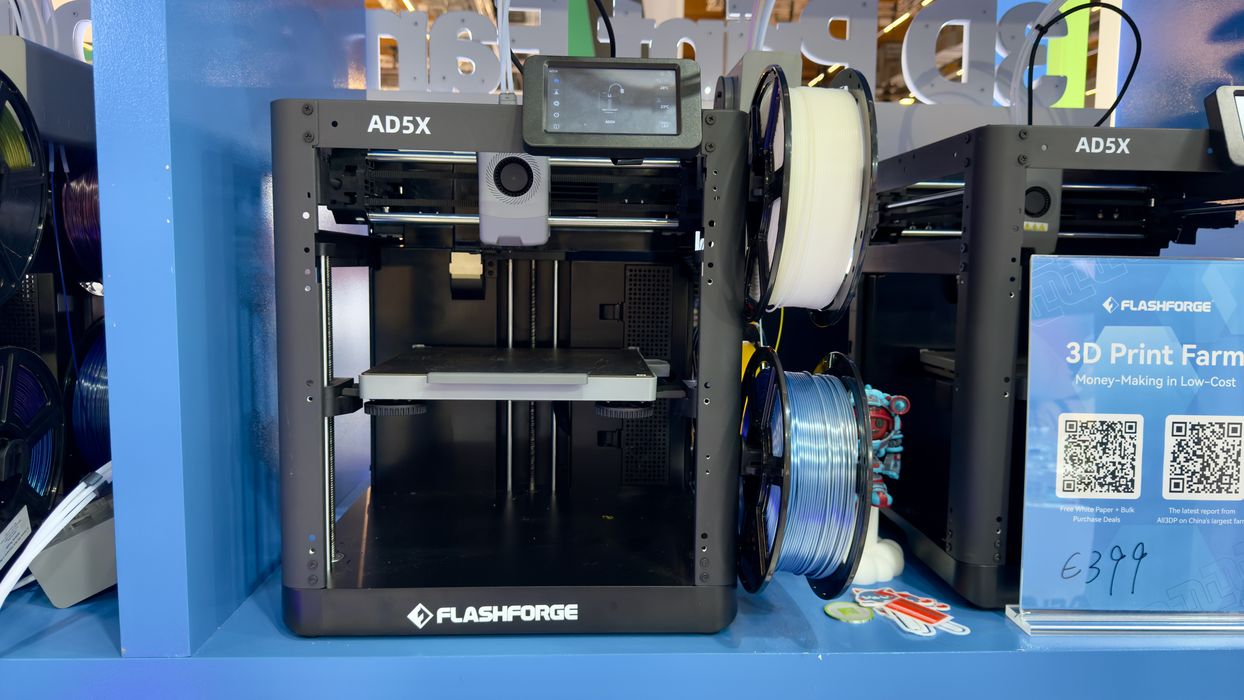

Let’s start with the printer characteristics. The AD5X has a single toolhead with quick-swap nozzles. The default is the standard 0.4mm, but they also offer 0.6, 0.8, and 0.25 mm versions.

There is a standard magnetically attached spring steel print plate, coated with PEI for adhesion. The build volume is a very healthy 220 x 220 x 220 mm, about the same as the competitors.

I should mention that the AD5X is considered a high-speed 3D printer, as it can reach 600mm/s print speeds with 20,000mm/s/s acceleration. This is supported by the machine’s CoreXY motion system.

There’s a 4.3” color touchscreen, and there are all the usual convenience features, including automated calibration, filament run-out detection, etc.

In other words, the AD5X’s 3D printing components are about standard for these days.

What’s different? It’s the “Intelligent Filament System”, which allows the 3D printer to produce objects in up to four colors per job.

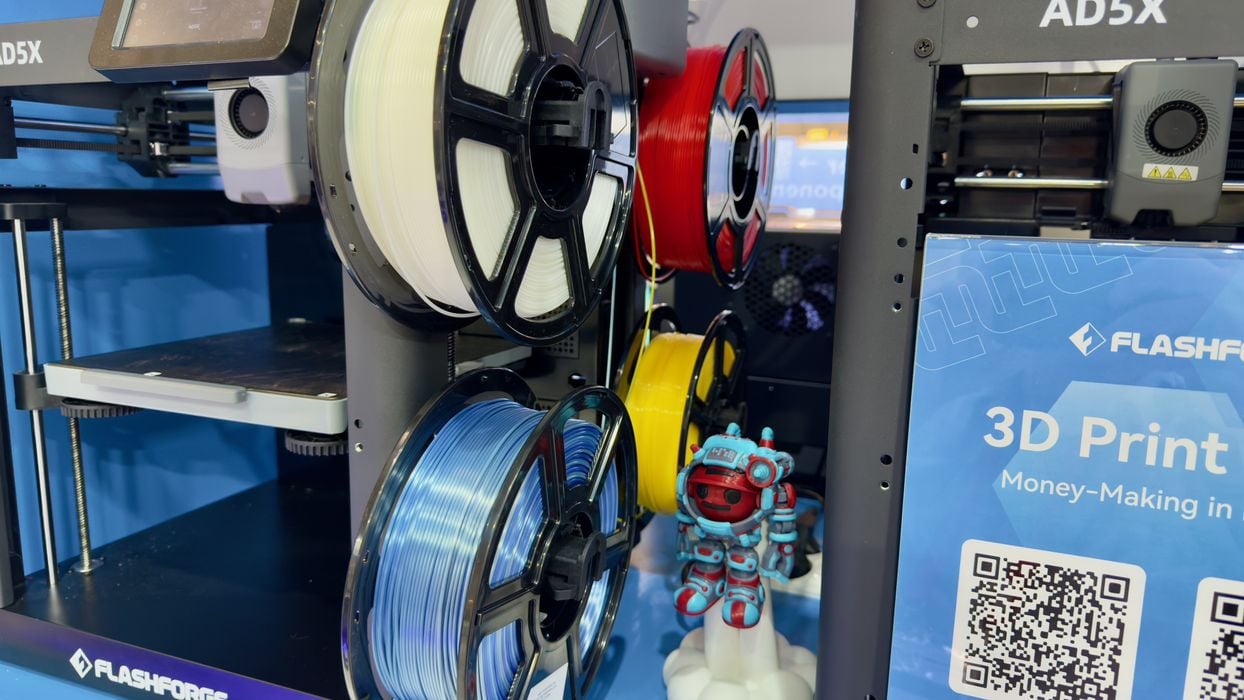

Functionally, this is very similar to several other “AMS”-style solutions from other providers. However, all of them require the use of an external accessory box to hold the spools and feed them to the 3D printer. The AD5X has none of that.

Instead, the four spools are simply mounted on the right-hand side of the machine, out in the open, as shown here. Instead of using a separate accessory, Flashforge has a simple box above the spools that feeds the filaments towards the toolhead. Even better, there’s no accessory at all: the base AD5X includes this feature.

There are some differences with the AD5X multicolor system. We were told that it is much faster to swap filaments than the competitors. As an example, they explained that printing the “Bee” here took only 16 hours on the AD5X, while the same print took 24 hours on an unspecified Bambu Lab machine.

They’ve also optimized the “poop” process. On many multicolor 3D printers, there is a requirement to purge from the nozzle the previous material, and most machines “poop” out a small blob of this material. On some complex print jobs, the amount of poop can be considerable, even exceeding the model’s material. Flashforge representatives told us they have “optimized” the poop process to save on filament.

The most interesting aspect of the AD5X filament swapping system is that it is apparently able to handle TPU material. This is almost always impossible using other four-spool systems due to the spaghetti-like nature of the material: it’s hard to push it up a tube. I’m not exactly sure what Flashforge has done here, but they do claim to handle TPU very well. It is likely they can handle only “harder” TPUs.

The introductory price for the AD5X was a mere US$399, which is quite a bit lower than competing four-color machines that require a separately priced accessory. For example, a Bambu Lab P1S, which most closely matches the AD5X, is priced at US$949 when combined with the AMS unit.

However, the P1S Combo is now on sale, and Flashforge has sold out their initial batch of AD5X units. Flashforge has set the current price for the AD5X at US$449, still a bargain over most other options.

Via Flashforge