Charles R. Goulding and Preeti Sulibhavi explore how Dallas, Texas, and Southern Methodist University are driving economic growth and 3D printing innovation, cementing the city’s status as a global hub for technology and business.

Dallas, Texas, is a thriving economic powerhouse in the United States, known for its diverse industries, innovation, and business-friendly environment. The city is home to numerous leading company headquarters, a robust 3D printing ecosystem, and a strong academic presence, including Southern Methodist University (SMU), which plays a pivotal role in advancing additive manufacturing technologies. This article explores Dallas’s status as a top city for business and innovation, its economic metrics, and its growing influence in 3D printing, with a special focus on SMU’s contributions.

Economic Metrics of Dallas: A Snapshot of Success

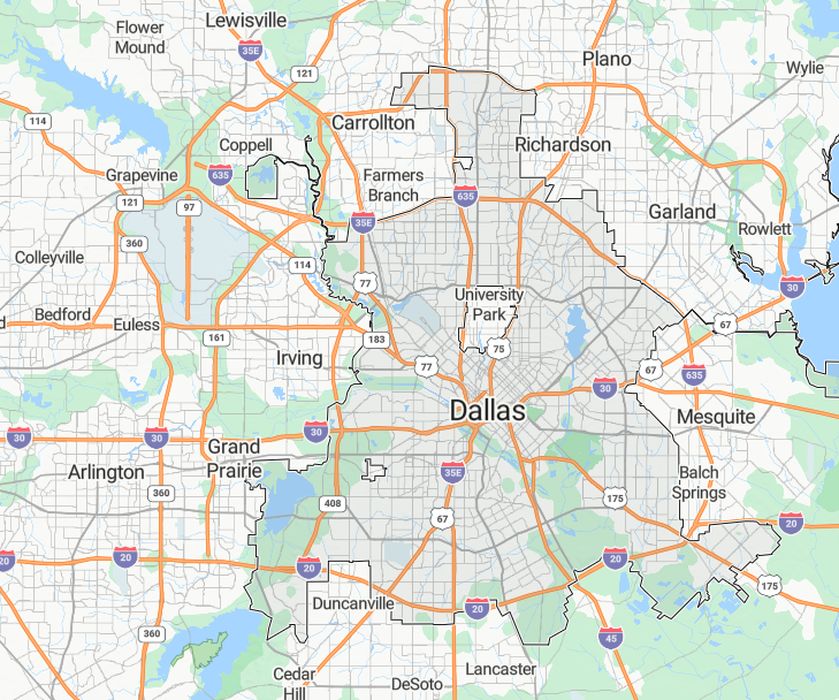

Dallas, the third-largest city in Texas, is part of the Dallas-Fort Worth-Arlington metropolitan area, often referred to as DFW. With a population of approximately 1.3 million and a metro area population of over 7.9 million, it is one of the largest metropolitan areas in the country. The city plays a crucial role in the state’s economy, contributing significantly to Texas’s GDP.

The DFW metroplex generated a GDP of approximately US$745 billion in 2023, placing it among the top economic contributors in the U.S. This figure underscores the region’s industrial diversity and economic vitality.

Dallas boasts a robust job market with diverse opportunities in industries such as technology, finance, healthcare, and manufacturing.

Leading Companies Headquartered in Dallas

Dallas is home to some of the world’s most prominent corporations, solidifying its reputation as a global business hub. The city attracts Fortune 500 companies due to its strategic location, pro-business policies, and extensive infrastructure. Some notable headquarters include:

- AT&T Inc.: A global telecommunications leader, AT&T is a key player in the Dallas economy and a symbol of the city’s innovation in technology.

- Southwest Airlines: Based at Dallas Love Field Airport, Southwest Airlines has transformed air travel with its unique low-cost business model.

- Tenet Healthcare: As one of the largest healthcare services providers in the U.S., Tenet Healthcare underscores Dallas’s influence in the healthcare sector.

- Texas Instruments: A pioneer in semiconductor manufacturing and technology development, Texas Instruments is a pillar of Dallas’s tech ecosystem.

- ExxonMobil: Though officially based in nearby Irving, ExxonMobil has strong ties to Dallas, contributing to the city’s energy sector prominence.

These companies not only drive economic growth but also create synergies for innovation, research, and development in emerging fields such as 3D printing.

Dallas as a Center for 3D Printing Innovation

The emergence of 3D printing has reshaped industries worldwide. Dallas is a growing hub for this technology, offering a vibrant ecosystem of companies, academic institutions, and resources that make it a leader in the field.

Dallas hosts numerous companies specializing in 3D printing technologies. These firms cater to industries like healthcare, aerospace, automotive, and construction by providing innovative solutions and fostering collaboration:

- PrintParts: A local leader in additive manufacturing services, PrintParts focuses on customized 3D printing solutions for prototyping and production.

- EOS North America: With a focus on industrial-grade 3D printing technologies, EOS supports Dallas’s growing demand for advanced manufacturing tools.

- Additive Manufacturing Consortiums: Various Dallas-based organizations and consortiums bring businesses together to explore advancements in materials science, software, and large-scale 3D printing.

The Dallas Library is home to Creative Spaces, new “makerspaces” carved out of vacant rooms in the J. Erik Jonsson Central Library with each space serving a specific creative endeavor. These different “spaces” could be for storytelling, fiber arts, and preservation or the heritage lab. The library provides unique equipment and technology to allow the public to get a hands-on experience, build new skills or try a new hobby.

SMU: Driving Innovation in 3D Printing

Southern Methodist University (SMU), a prestigious institution located in Dallas, is at the forefront of 3D printing research and education. SMU’s contributions to the field have solidified its status as a vital player in the region’s additive manufacturing ecosystem.

SMU’s Facilities and Programs

SMU hosts state-of-the-art 3D printing facilities, offering students and researchers access to cutting-edge technologies. These include:

- The Deason Innovation Gym (DIG): A hands-on makerspace that encourages collaboration among students, faculty, and industry professionals. Equipped with advanced 3D printers, laser cutters, and other tools, DIG enables the creation of complex prototypes.

- The Hart Center for Engineering Leadership: This center fosters industry partnerships, helping students apply 3D printing skills to solve real-world problems.

- Interdisciplinary Research: SMU integrates 3D printing into various fields, including mechanical engineering, biomedical research, and material science, promoting cross-disciplinary innovation.

SMU’s curriculum emphasizes both theoretical and practical aspects of 3D printing, ensuring that graduates are well-prepared for careers in this evolving field. Courses cover: Additive manufacturing design principles, Materials used in 3D printing, and Applications of 3D printing in healthcare, aerospace, and industrial sectors.

SMU is also a leader in cutting-edge research projects, exploring topics such as:

- Advanced Materials: Developing new materials that enhance the strength, flexibility, and durability of 3D printed components.

- Bioprinting: Investigating the use of 3D printing to create artificial tissues and organs, contributing to advancements in regenerative medicine.

- Sustainability: Addressing environmental challenges by developing eco-friendly and recyclable 3D printing materials.

SMU actively collaborates with Dallas-based companies to bridge the gap between academia and industry. These partnerships drive innovation by applying university research to practical challenges in manufacturing, healthcare, and beyond.

The Future of 3D Printing in Dallas

The outlook for 3D printing in Dallas is bright, with continued investment and interest from academic institutions, businesses, and government agencies. The city’s ecosystem provides fertile ground for advancing the technology in ways that benefit various sectors.

As 3D printing becomes more integral to manufacturing and healthcare, Dallas is well-positioned to capitalize on its potential economic impact. The technology reduces production costs, shortens supply chains, and enables customized solutions, all of which contribute to the city’s competitiveness.

With institutions like SMU leading the charge, Dallas is creating a workforce skilled in additive manufacturing. These efforts ensure that the city remains a leader in innovation and can meet the demands of industries adopting 3D printing.

Dallas’s support for startups and small businesses in the 3D printing sector will continue to drive innovation. Incubators, accelerators, and funding opportunities are likely to attract more entrepreneurs to the city. These innovative businesses contribute to the city’s reputation as a leader in high-tech manufacturing and prototyping.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes are typically eligible expenses toward the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software can also be an eligible R&D expense. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Dallas, Texas, is a top-tier city not only for its economic contributions and company headquarters but also for its role in advancing 3D printing technologies. The city’s combination of industry, academia, and entrepreneurial spirit fosters an environment of innovation. Southern Methodist University stands out as a key player, providing the resources, research, and talent necessary to push the boundaries of what 3D printing can achieve. As Dallas continues to grow, its impact on business and technology will resonate on a global scale.