I saw a new 3D print nozzle technology that can print tubular extrusions.

The technology is called “Blow Extrusion”, or “BX” by the developers who perform research at TU Darmstadt.

At the top you can see some rather coarse-looking colorful structures 3D printed using this technique. At first they seem to be just a simple, but fat, extrusion from an FFF device.

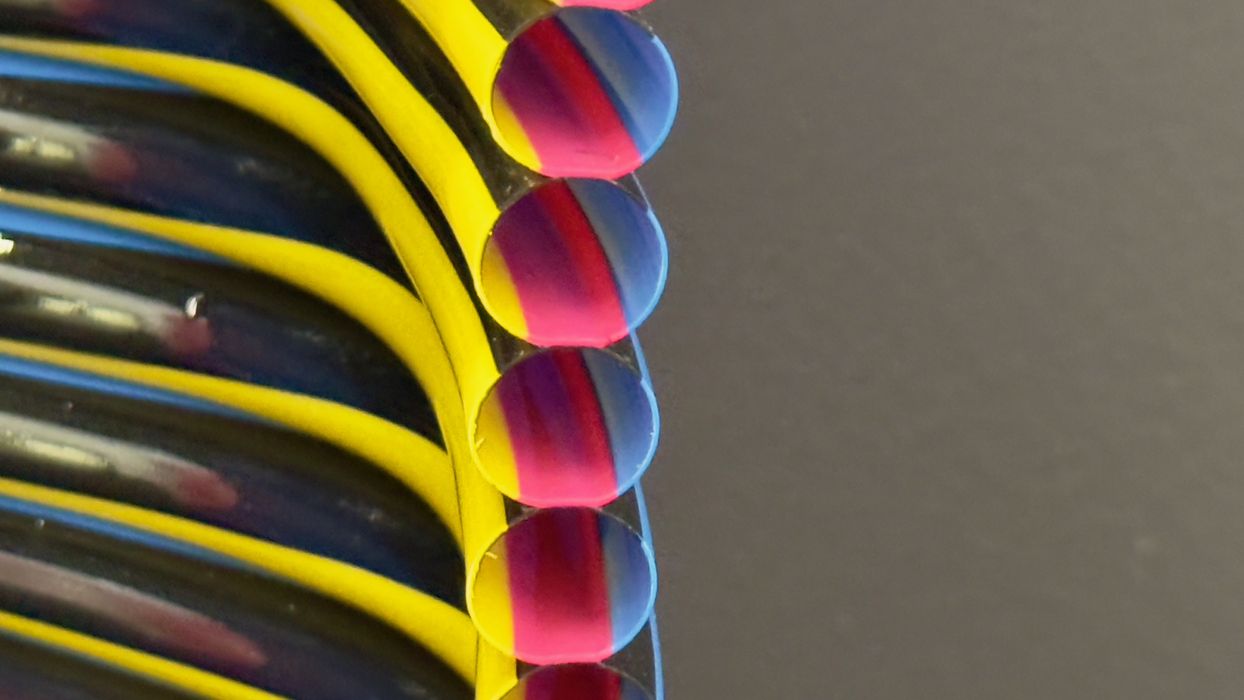

However, when you look more closely you see this:

The extrusions are hollow and quite wide. This makes the objects quite lightweight, and the extrusions are very reminiscent of plastic drink straws.

How has this been accomplished? It turns out there were two elements combined to make this work.

First, the nozzle is coaxial. In other words, there is a central obstruction in the nozzle, which forces material to the sides. Secondly, there is a mechanism to blow air into the extrusion as it emerges, through the center of the coaxial nozzle.

The amount of air is precisely controlled, and this enables the system to extrude tubes of different diameters, with varying wall thicknesses to match.

You’ll also note there are different colors involved in these prints. This was achieved with a four-filament mixing hot end, and the researchers were able to print two interesting mixes shown at the top:

- Transparent PETG with Magenta PETG

- Mix of Cyan, Magenta, Yellow, and Black PETG

This is a research project at this stage, but it seems like a very promising technology. While it definitely does not produce strong parts, it could be quite useful for printing larger-scale objects, decorative, and display items. These would be very lightweight and consume very little material as compared to alternative 3D print processes.

I expect some entrepreneurs will adopt this tech and develop it into a commercial project in the future.

Via TU Darmstadt