There seems to be a new emerging standard configuration for desktop FFF 3D printers.

Historically, desktop FFF 3D printers were open-gantry affairs, with a standard i3 motion system design. This approach is known as the “bedslinger” style due to the rapid back and forth movement of the print plate in the Y-axis.

The bedslinger approach became popular because it was inexpensive to produce and actually worked pretty well. The inexpensive nature was largely due to the reduced number of parts required to build the machine: it’s open to the air, and there was no immediate need to provide an enclosure for most operators.

This led to two classes of FFF 3D printer: the inexpensive bedslingers, and the usually much more expensive enclosed systems that tended to be used by professionals.

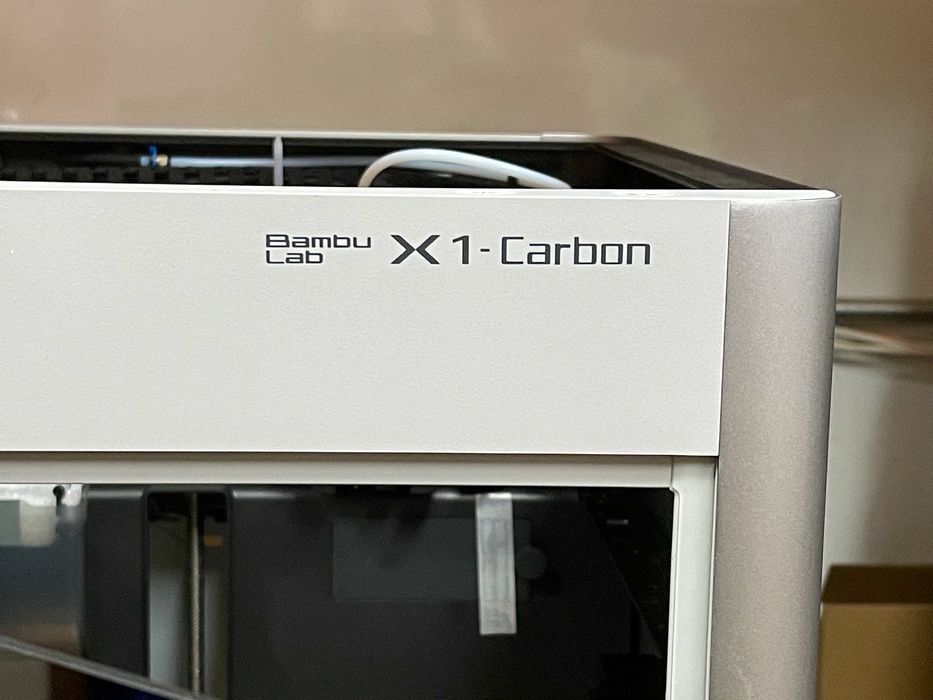

That state existed for some time until Bambu Lab appeared on the scene two years ago with their breakthrough X1C device. This machine offered the advantages of the professional enclosed systems, and vastly faster printing at a much lower price point: a price point dangerously close to bedslinger pricing. The machine also had a slick user interface that made it incredibly easy to use.

After initial skepticism, the company rapidly gained attention and huge sales followed. Today industry analysts suggest that Bambu Lab is the fastest growing 3D printer manufacturer, worldwide.

How does that leave the other 3D printer manufacturers? They were all in a challenging position, having an unexpected new competitor with a faster, cheaper, and easier-to-use product. Most of the companies began working to match Bambu Lab’s capabilities, but often this required a few product iterations.

Now, a year or so later, it seems that we have arrived at what appears to be a new standard configuration for a desktop FFF 3D printer. It looks something like this:

- Fully enclosed with a transparent front door

- CoreXY motion system

- Klipper or similar high-speed firmware

- Color touchscreen

- Build volume around 200-300 mm cubed

- Fully automated calibration

- Some level of automated quality control detection

- Networking with cloud monitoring and control

- Integration with a 3D model library

- All-metal hot end capable of 300C temperatures

- Power failure recovery

- Integration with a filament swapping accessory for multicolor prints

- Integration with a filament drying system for engineering materials

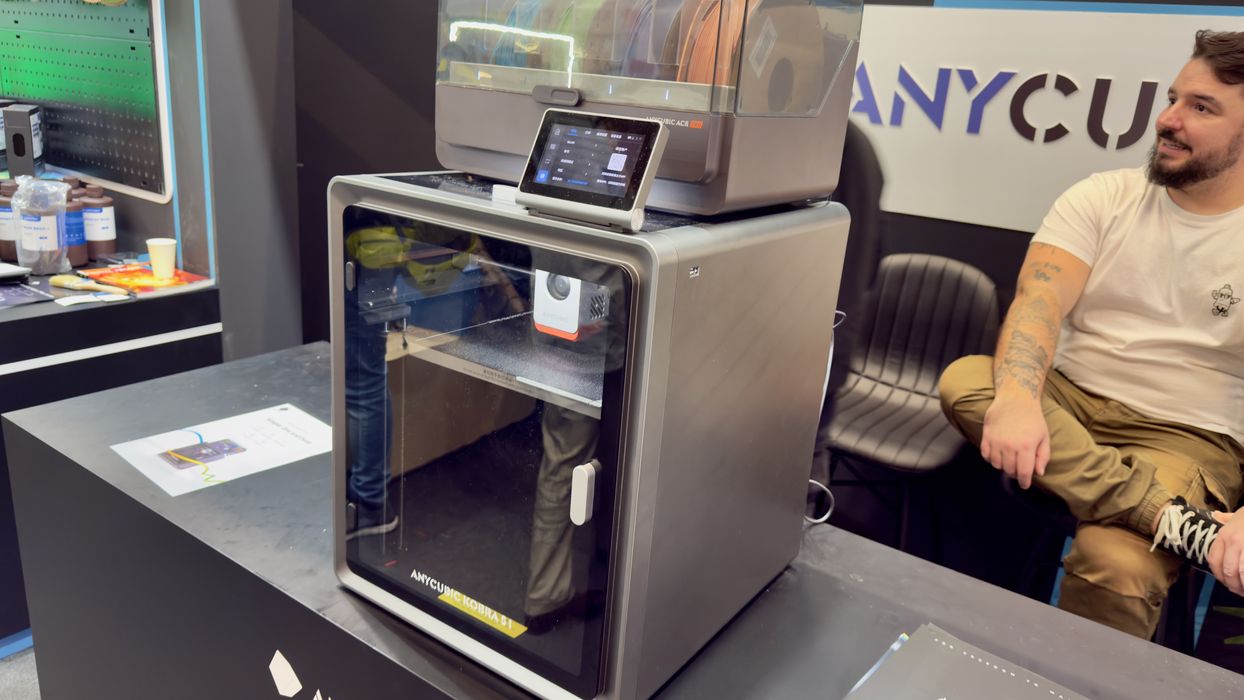

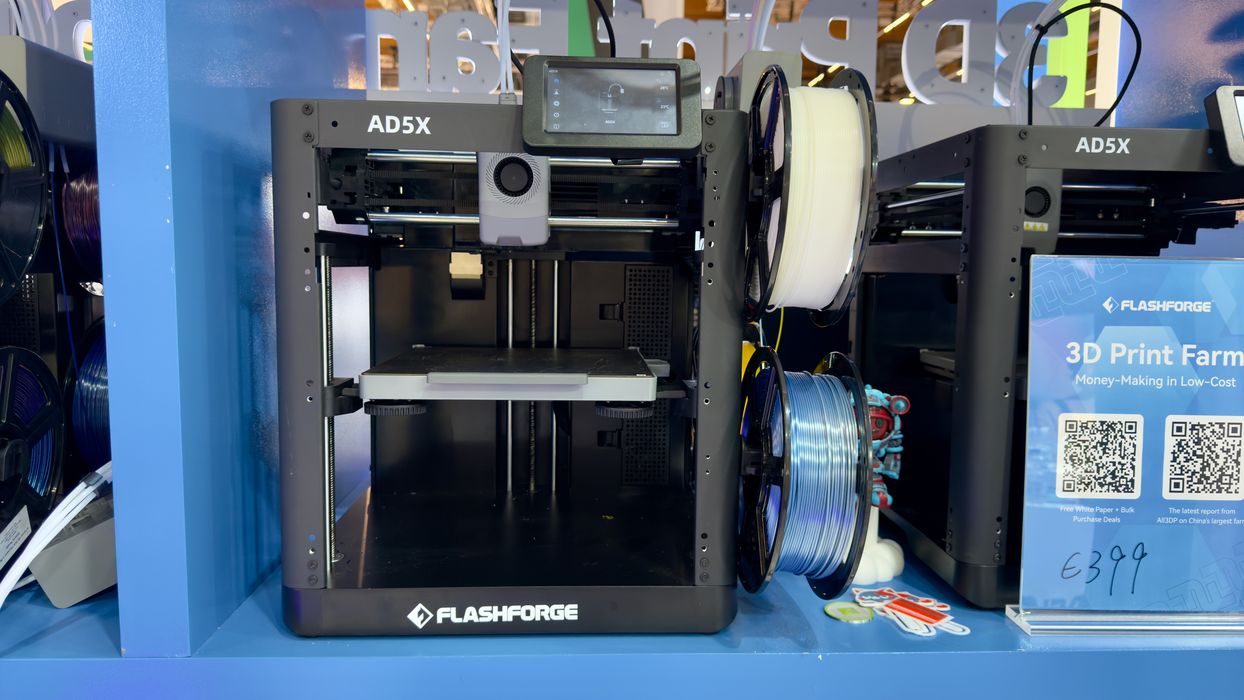

If that sounds much like a Bambu Lab X1C / P1S, it should. But we now see a series of similar machines from competitors, including Anycubic, Flashforge, Creality, and others.

Even Prusa Research surprisingly announced a machine very much fitting this pattern last week. The company had long been the champion of bedslingers, and the new Prusa CORE One moves the company into the new pattern.

To me, this announcement effectively signaled the end of the i3 style as the leading configuration for desktop FFF 3D printers. I also wonder about Prusa Research customers that recently purchased their also still new MK4S bedslinger: the CORE One is a better device.

Creality introduced their K1 series quite a while ago, and there are similar machines coming from Elegoo (Centauri Carbon, shown at top), Anycubic (Kobra S1), and others.

Clearly, this is the new competitive format that the market will begin to expect from desktop 3D printers.

While the bedslinger approach will likely persist, I expect it will begin to slide into the ultra-low price range because high-speed printing is just better on a CoreXY motion system. At very low price points, the sales margin will be very low, and that will likely trigger further consolidation in the industry.

There are probably dozens of cheap bedslinger brands that will disappear over the next year, as it will be extremely difficult for these low-margin companies to match the technology of the new standard machine configuration. It will be increasingly difficult to sell advanced-function bedslingers when faced with powerful new devices and ultra-low-cost bedslingers.

My only question is, what exactly do we call this new standard configuration?

Welcome to the new world of desktop 3D printing!