VoxelFill is one of the most intriguing new slicing features we’ve seen in recent years.

The new feature was developed by Create it REAL and AIM3D in a collaborative effort.

Create it REAL is a Danish company that specializes in slicing technology for 3D printing. They’ve introduced several interesting features in their REALvision software, which is often bundled with industrial and professional 3D printers.

AIM3D, based in Germany, is a manufacturer of industrial 3D printers using the FGF process. Pellet 3D printing is highly attractive when printing large parts, as the material cost is much cheaper.

What is VoxelFill? Imagine the following sequence when printing using either the FFF or FGF processes:

- As layers are deposited, a void is created inside the part. This typically happens with sparse infill

- Eventually the layers begin to converge at the top of the void

- Just before the void is closed over with a final layer, the printhead moves directly over top the void

- The extruder then pumps the void full of material

- The void is sealed and the printhead continues on its way to complete the print job

- This process repeats for every void in the part, significantly strengthening it

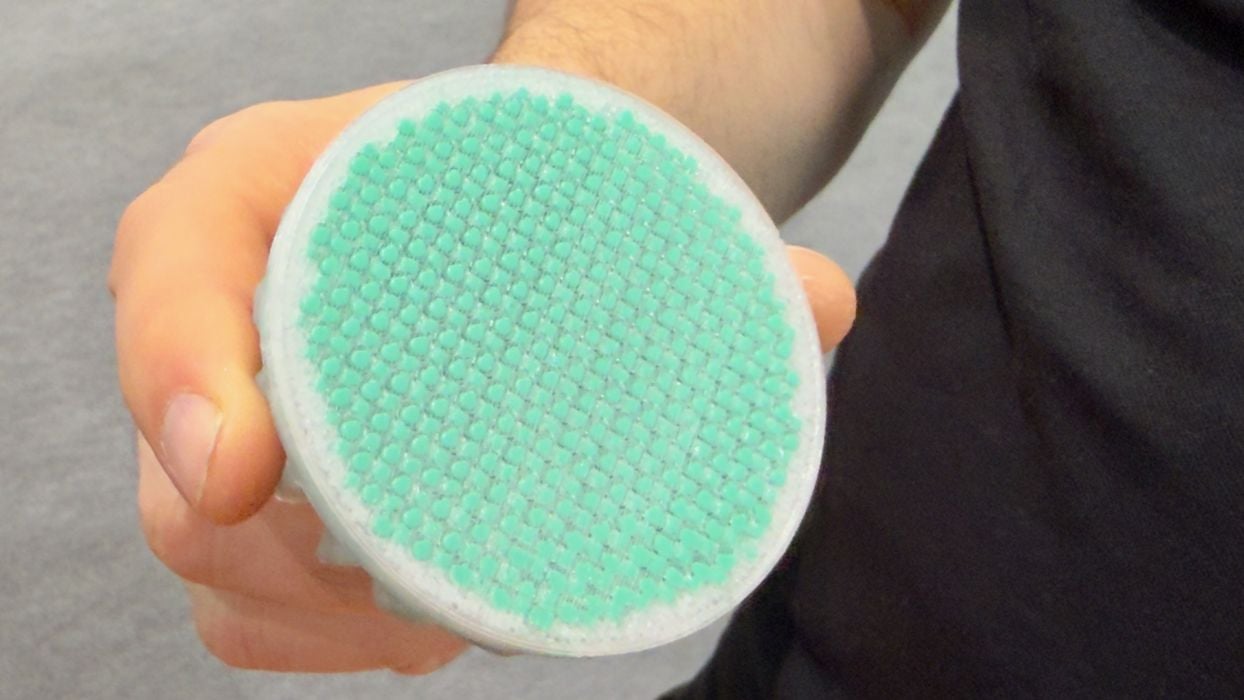

That’s VoxelFill: it completely fills voids within a print job.

Hold on, you ask, “Why not just print the part with 100% infill?”

That’s a great question, and the answer has to do with layer adhesion. The weakest part of any 3D print is between the layers. While material extruded strongly bonds with itself, its bond with the previous layer isn’t as good because the prior layer has already cooled somewhat.

This is why most 3D prints tend to break along the layer lines: that’s the weakest point.

VoxelFill does away with this problem entirely because the “dump” into the voids is not a layer. It’s a 100% contiguous zone of material that strongly bonds with itself through multiple layers. This makes the parts much, much stronger in the Z-axis.

It’s even stronger when using fiber-reinforced materials. Normally when carbon fiber-infused filament is used, it can make parts much stronger. However, as this material passes through the nozzle, the chopped carbon fibers tend to align with the material flow. This is less optimal, for strong parts.

When using carbon fiber — or any fiber reinforced material — with VoxelFill, the fibers are randomly oriented when filling the voids. This makes these parts even stronger, and much closer to an injection molded part. According to Create it REAL, these parts are approximately 80% the strength of pure injection molded parts.

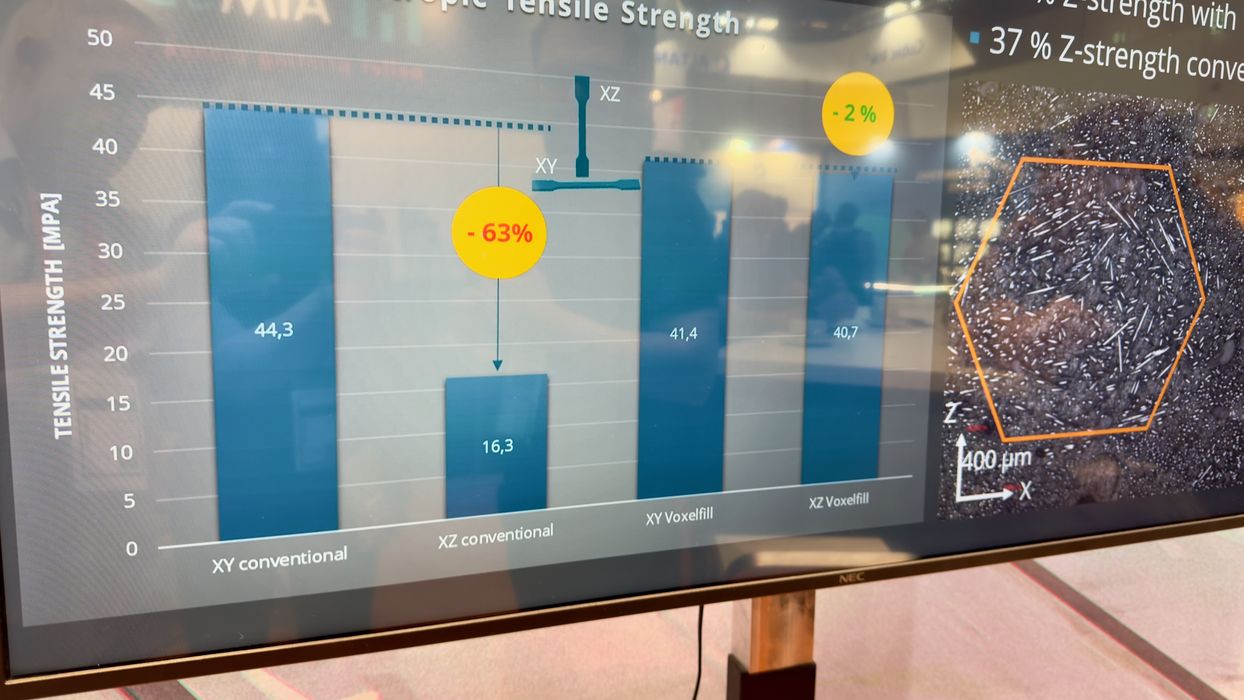

On this chart, AIM3D has measured the XZ strength about equal to the XY strength, meaning the parts are basically isotropic. This is quite different from the two columns on the left, showing the typical difference between XY and XZ strength.

How did this collaboration come about? It turns out that AIM3D had a patent on the concept from around 2020. However, they are a 3D printer manufacturer, and didn’t have the expertise to implement the concept themselves.

They partnered with Create it REAL, which is a slicing software company accustomed to building unusual features for clients. Even better, the REALvision slicer already has the capability for programmable foam, where voids of predictable size are generated. It seems that it was relatively straightforward to develop the VoxelFill feature on top of existing code.

For now, AIM3D is the only 3D printer manufacturer offering VoxelFill through their bundled REALvision slicing software. All AIM3D machines now have access to the feature, which doesn’t require any hardware changes: it all happens with standard FGF / FFF nozzles.

Could VoxelFill appear in other slicing software? It’s possible, as AIM3D, the patent owners, told us they are “open for discussion”, and that at Formnext last week they had “significant interest” from unnamed other parties.

Due to the commercial nature of and patents for VoxelFill, it’s unlikely it could make its way into any of the open source slicing tools, including UltiMaker Cura, PrusaSlicer, OrcaSlicer, etc. However, it may be that VoxelFill could inspire a similar but different approach that might be open sourced for those tools.

Via Create it REAL and AIM3D