JuggerBot3D announced a new 3D printer variant, the P3-44 ASTRA.

The company’s P3-44 has been around for a while, and it’s quite an impressive large-format pellet 3D printer using the FGF process. What’s different about the ASTRA variant?

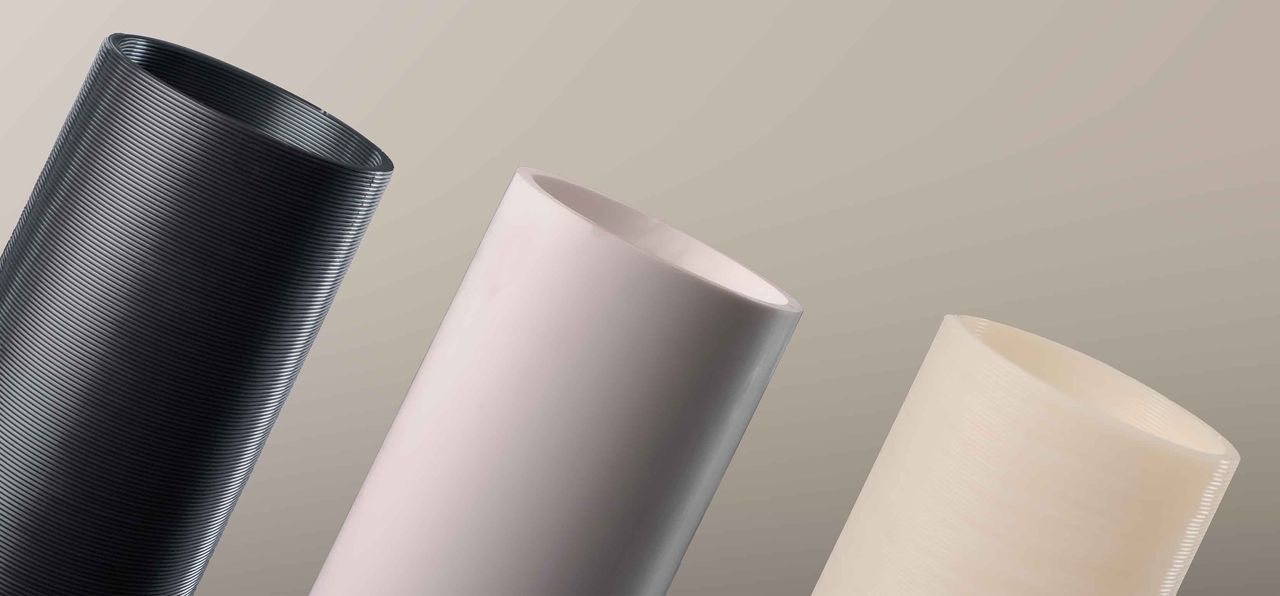

It can print PVC thermoplastic.

PVC is a highly versatile material used across industries for many applications. The material is highly resistant to chemicals, its flame resistance, and its strength for structural and mechanical applications.

Why hasn’t this wonder material been 3D printed previously? There’s just one problem.

PVC is an abbreviation for polyvinyl chloride, and it’s the “C” that’s the problem. The “C” is chlorine, a highly dangerous material. It’s used to purify pools and also used as a weapon of mass destruction in wartime gas attacks.

You don’t mess with chlorine, but that’s what you’ll be doing if you heat PVC, which can off-gas chlorine.

JuggerBot3D worked with IPEX Technologies, a company that specializes in making PVC processing safe. They adapted a number of features in the P3-44 to transform it into a PVC-printing device that is entirely safe.

What was changed? JuggerBot3D provided quite a list of modifications:

- Prevention: Corrosion-resistant components extend the printer’s lifespan while ensuring PVC processing control. ASTRA has been outfitted with hardware to mitigate these issues and key control components to maintain extrusion temperatures.

- Containment: Processing PVC may release other VOCs that could be harmful over time, making proper containment essential for workplace safety. Additional sealing areas across the already enclosed base P3-44 ensure fumes generated during printing stay within controlled zones.

- Extraction: Equipped with a dual-stage fume extraction system, ASTRA captures fumes emitted throughout the printing process.

- Protection: Improper processing of these materials can produce issues in the production environment. Access to the chamber is prohibited to prevent premature access, ensuring the environment is clear of fumes before the system is opened.

The result is a device that can 3D print PVC objects, something we haven’t seen previously. This could be quite significant, as today’s PVC production typically involves molding, which limits the possible geometries. The P3-44 ASTRA unlocks untold dimensions of design possibilities.

However, JuggerBot3D will no doubt encounter the same problem as every other 3D print innovator: they will have to persuade the existing PVC manufacturers that this is a good idea. The notion of making radically different parts enabled by 3D printing is not something that comes naturally for many companies. That persuasion is very challenging and could take some years before the light goes on.

Nevertheless, JuggerBot3D has broken through another barrier in the world of 3D printing: PVC can be printed!

Via JuggerBot3D