Is it possible to 3D print solder? That seems to be the case, as a motorsport company developed a machine to do exactly that.

The group in question is Bad Obsession Motorsport, a UK operation that provides technical services to rally car drivers. One of their projects is to build the “world’s fastest Mini”, a popular small-format automobile made in the UK.

“Project Binky”, as they named it, has evolved into an ongoing series of YouTube videos where the group slowly develops the components for the vehicle. The latest episode, which is their 39th in the Project Binky series, focuses on developing the instrument panel for the vehicle.

Buried deep into the episode is a very interesting experiment where they developed a device to print solder. The issue they were solving was how to create the circuit board for the instrument panel, which would hold the speedometer, tachometer, warning lights, etc.

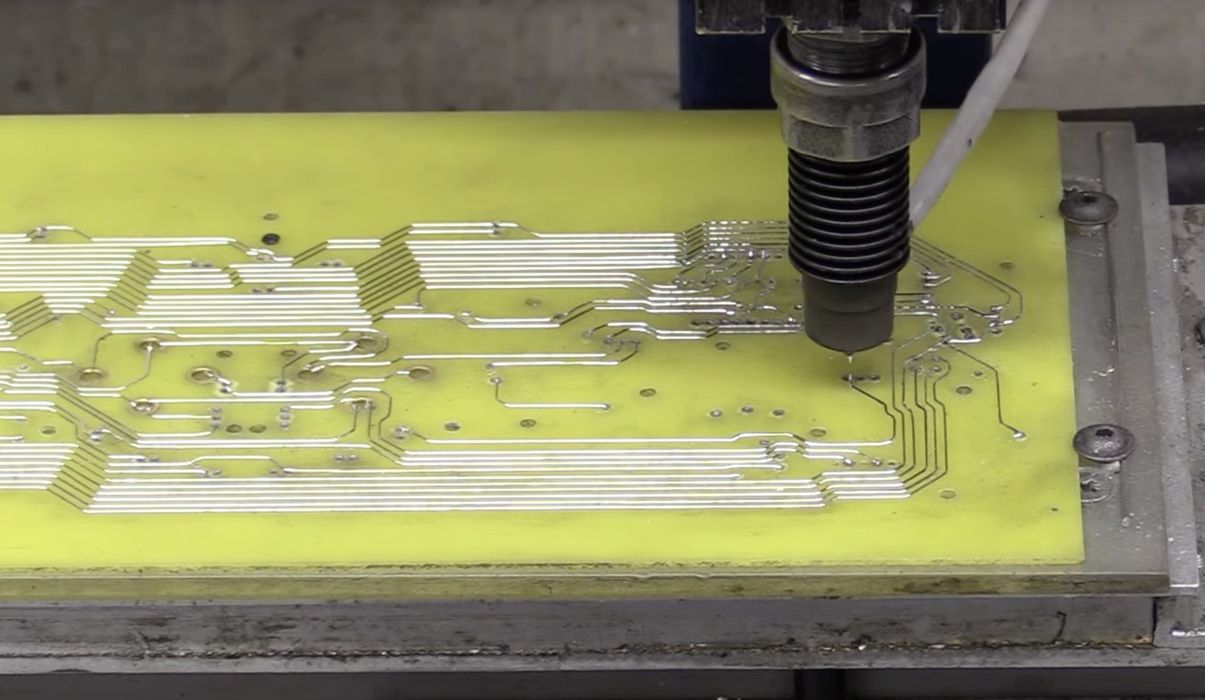

This required quite a number of electrical traces for all the lighting, and they invented a machine that could print solder traces directly onto the blank circuit board.

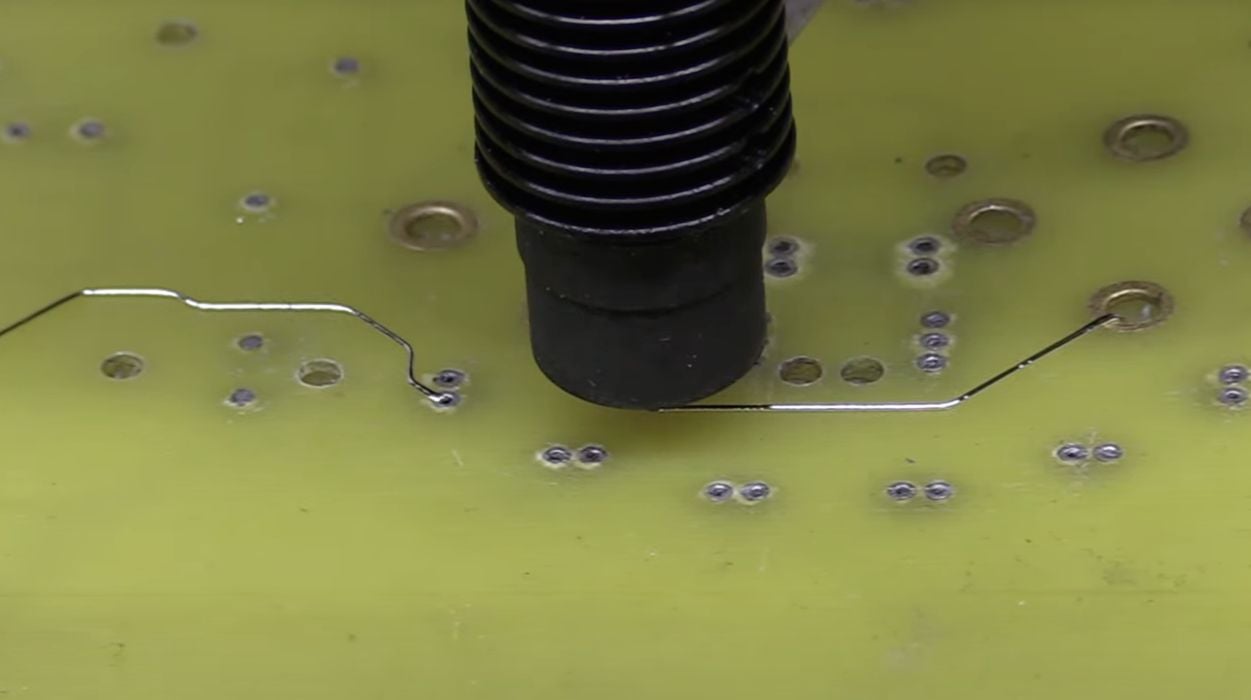

As you can see at top, the system involves a CNC-controlled hot end, which looks rather similar to a FFF 3D printer hot end. This melts the solder, which then is deposited on the toolpath.

They were able to use this approach to complete a rather intricate circuit board, shown here.

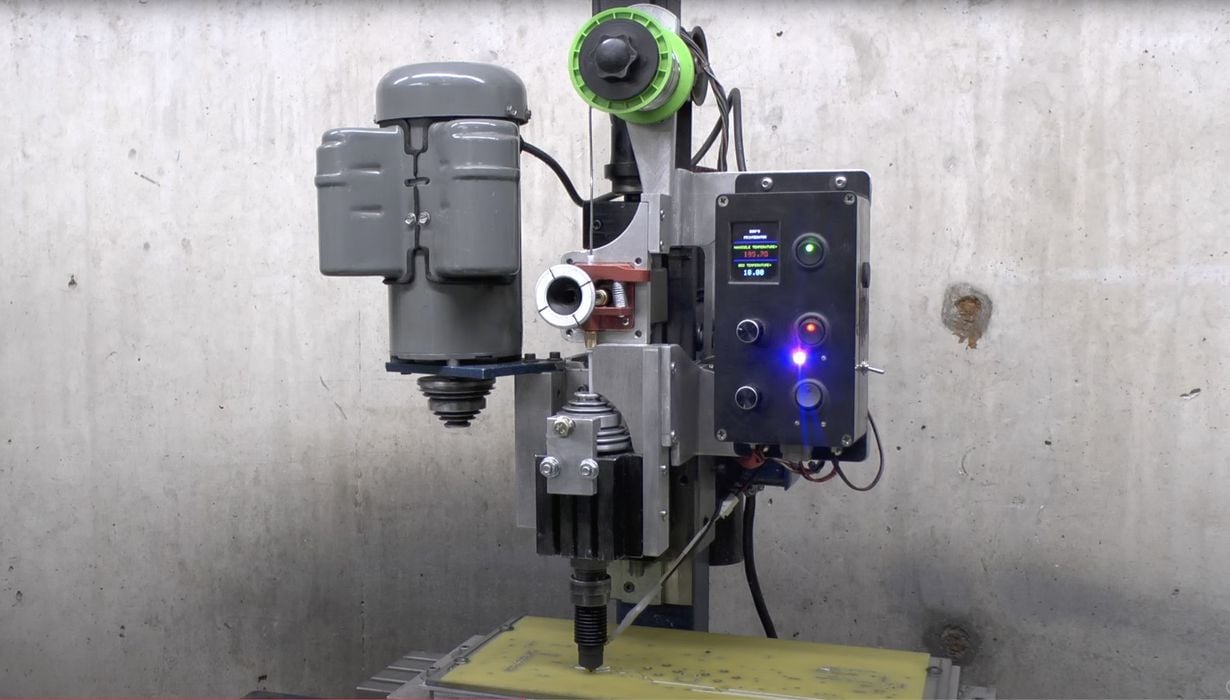

But is this a 3D printer? Although they refer to it as their “3D printer”, it isn’t really a 3D printer: it prints only in 2D. They simply adapted a CNC milling machine to do the printing. A hot end was added to the toolhead, and they experimented with different solder mixes until they got one that worked well.

What I found of most interest in this project was the fact that they were able to print solder using a printhead. If they can do it on a CNC mill, then it should also be possible to do so on a standard FFF 3D printer.

Why even attempt this? The idea would be to have a second toolhead on a FFF 3D printer, with the primary toolhead depositing polymer. The second toolhead could deposit solder traces embedded inside the print. It might even be possible to embed traces that have 3D paths throughout the structure.

To be clear, 3D printed circuits are not a new thing. There have been countless versions of that technology developed over the past decade. However, many seem to suffer with poor conductivity, poor resolution and other issues.

Here we have what appears to be a rather straightforward setup involving basic tooling and commonly available materials. If this can be done for 2D solder printing, then why not for 3D?

Via YouTube and Bad Obsession Motorsport