An entirely new and incredibly fast method of 3D printing has been developed that is based on sound: HDSP.

Researchers previously discovered the ability for sound to perform chemical reactions. The process revolves around cavitation, the phenomenon that occurs when high frequency oscillations (sound) are introduced to a fluid. The cavitations create bubbles, much like you’d see if a high speed propeller make in water.

By fine tuning the oscillation it is possible to generate extreme heat when the bubbles collapse. This heat can be used for a variety of chemical processes, including polymerization of resin. This process is called a sonochemical reaction.

Now that we understand sonochemical reactions, one can easily imagine how this could be transformed into a 3D printer: a toolhead produces a sound focal point of an appropriate frequency, and it is moved around in some resin to build an object.

That’s quite interesting, but the researchers went much, much farther. Instead of having a single focal point with a toolhead, they instead produced a sound hologram. The process is called “HDSP”, Holographic Direct Sound Printing.

The hologram is a three dimensional pattern of varying sound frequencies that is static in 3D space. This would cause resin to solidify at any points in the hologram that have the appropriate frequency. In other words, the object would form all at once in three dimensions.

That is utterly different from typical layer-by-layer 3D print processes that are quite slow to produce objects. Volumetric 3D printing is somewhat similar to HDSP, but uses light rays. More on this in a moment.

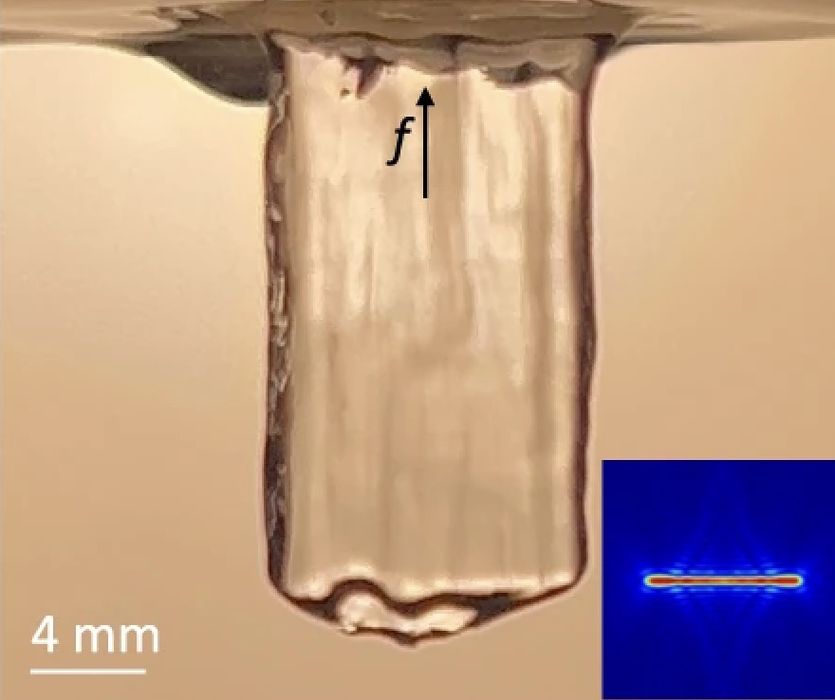

The researchers built a prototype device that implements HDSP, and were able to demonstrate its ability to produce solid objects. It seems that the build volume of their prototype was somewhat small, so their approach was to have a robot arm “pull” solidified material out of the build volume as shown in this video:

The process is quite rapid, and produces objects without layer lines. The small 3D printed wall below, 15 x 20 mm, was produced in 30-90s.

The researchers explored HDSP in depth and determined different printing parameters, including acoustic power, frequency, pulse periods and more. These are all quite different from the parameters used in other 3D printing processes.

One big advantage of HDSP is that it, like SLS, is able to print multiple objects within the build volume. That’s because the entire build chamber would be printed at once, and there is no need for support structures. Future commercial versions of HDSP could potentially have high part throughput.

Sound waves can travel through opaque materials, unlike lightwaves. This means it would be possible to print in resins that are opaque and potentially including additives to provide a wide range of engineering properties.

Another incredible capability of HDSP is that because sound waves can travel through solid objects, it would even be possible to print “behind a wall” by beaming the sonic hologram into that space. Imagine, for example, pouring a resin into a large wall-sized mold, and then triggering the hologram to solidify the resin into a pattern. Then the remaining resin is drained and wall removed to reveal a large complex object.

It would also be possible to print in multiple materials. Imagine the above scenario again, but after draining, a second and different resin is poured in. A second holographic pattern then is triggered to solidify the second material. This could continue for as many materials as required, so long as the resin can flow to the required locations.

The development of HDSP is a major milestone in 3D print technology. While it is only in the research stage, it is so promising that I am certain it will become commercialized in the near future.

Via Nature