I spoke with representatives from Additec to learn more about their new AMDroid system.

Additec has technologies to 3D print in metal, including their laser directed energy deposition system. It’s a “wire-laser” approach that uses standard feedstock wire with a powerful laser to melt the material at the toolhead. They also offer Liquid Metal 3D print technology, which they obtained last year by acquiring Xerox’s Elem Additive Solutions business unit.

The AMDroid uses their wire-laser technology to produce larger metal parts, but the interesting part is the packaging. Unlike many wire additive solutions that are standalone robots or even just a toolhead that you must install on your own robot, the AMDroid is a complete package, or “cell”, as some might call it.

The robot is included and set up in a safe enclosure, where larger objects up to 1800 x 1250 x 1370 mm can be quickly built.

The AMDroid is notably fast: it can deposit up to an amazing 4kg of metal material per hour. That material can be selected from a wide range of possibilities, including stainless steel, copper, aluminum, titanium and many more. These are easily handled by the quite powerful 6kW laser.

The robot included with the AMDroid is multi-axis (6+2), meaning it is able to handle some fairly complex geometries with its extra reach. Resolution is quite good, with layers as small as 0.8mm. That’s quite a bit finer than is found on many wire additive systems, and I suspect it’s because the laser provides a much smaller melt pool.

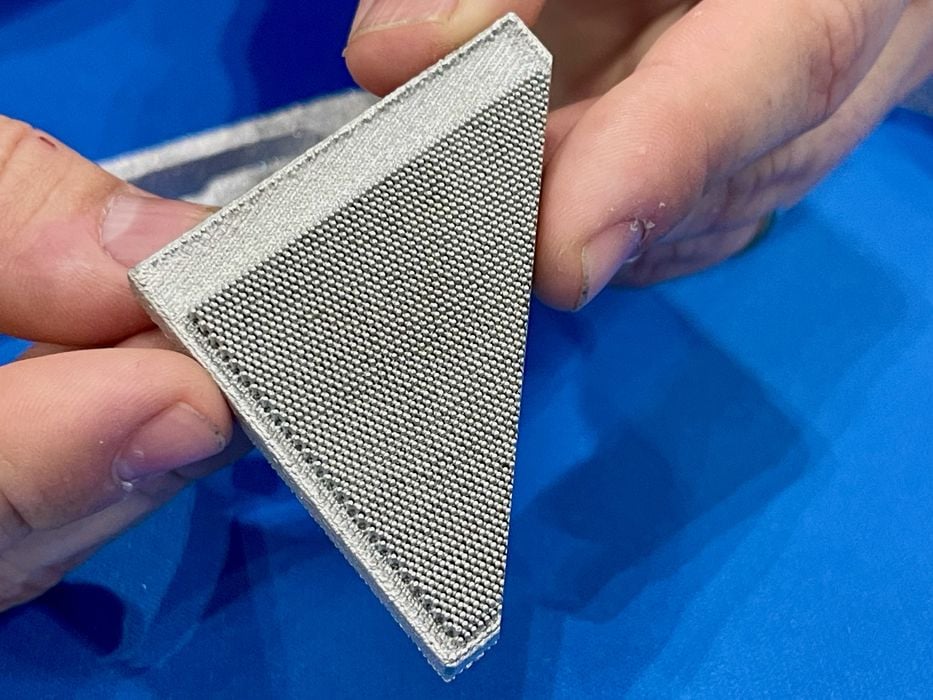

I was also able to take a look at some print samples from the company’s Liquid Metal technology, which is quite impressive. Here you can see extraordinarily fine details on a metal 3D print.

Complex 3D prints are quite possible using this technology.

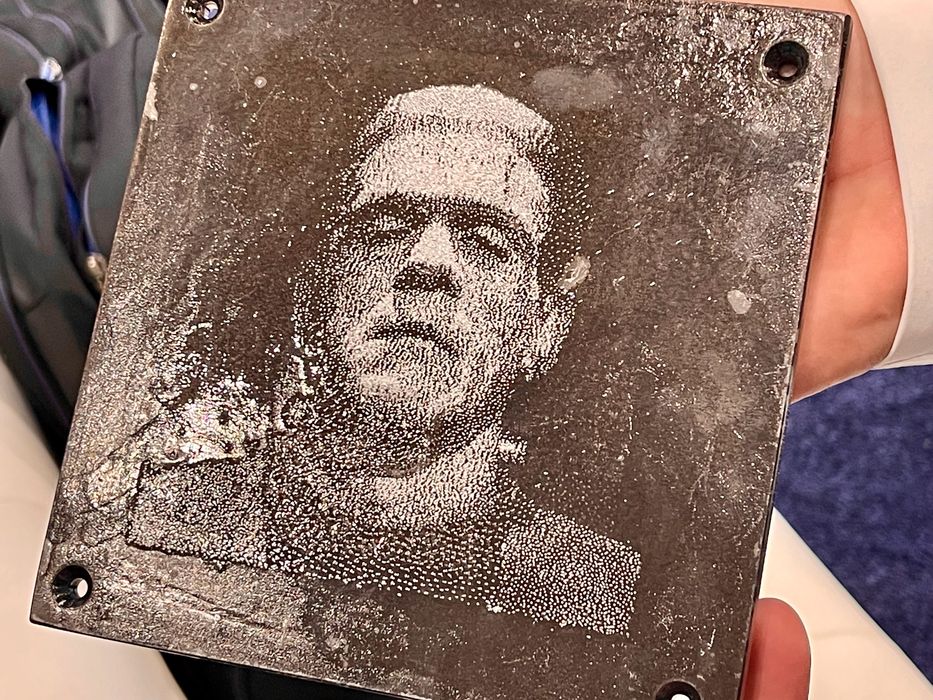

Here is something I haven’t previously seen done with metal 3D printers: a 2D image representation. The resolution of Liquid Metal seems to be more than sufficient to do this, although it’s not likely a practical application.

Additec’s two technologies offer good options for companies seeking metal 3D printing solutions.

Via Additec