Zaxe is developing a mysterious solution to the multimaterial waste problem.

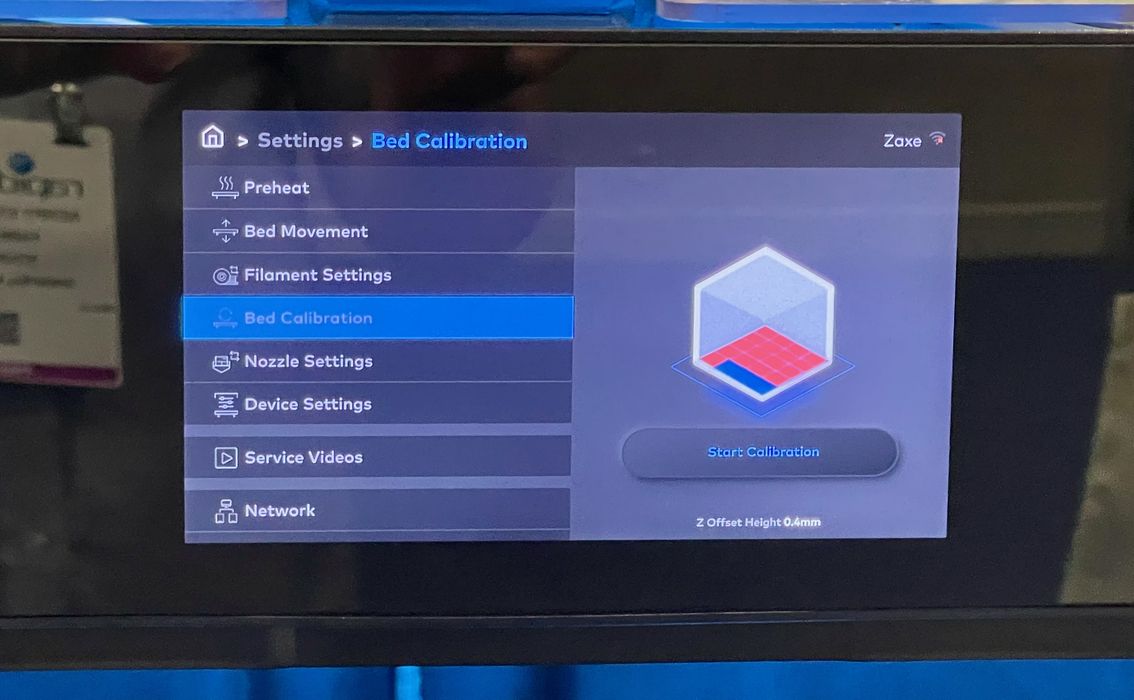

The Turkish company has been developing professional 3D printers for several years, and their latest machine is the Z3S, which is now sold in 35 different countries.

The device offers high speed 3D printing, able to reach speeds of 500mm/s, which are about 5-10X faster than typical machines of the past. This was accomplished with a CoreXY motion system, rigid frame, advanced firmware and a beefed up extrusion system.

The Z3S uses E3D’s Revo print heads, which are easy to swap and offer high flow capabilities.

The Z3S seems like a fine machine, and able to compete with others on the market at this time. But was more interesting was the discussion about the company’s next machine, the Z4.

This machine is apparently not being released until September, so we don’t know many details about it. However, we did learn that it will include IDEX capability for multimaterial 3D printing.

Multimaterial 3D printing is increasingly available from 3D printer manufacturers, and a variety of approaches are used to do so. However, many of these systems end up producing considerable amounts of waste plastic. They are also quite slow.

There’s one way to resolve the problems of speed and waste, and that’s to use multiple toolheads. However, that makes for a far more expensive machine due to the extra hardware required.

I asked about that aspect of the Z4, and was told that the Z4 “will save the speed and waste problem”. In other words, it could have the benefits of both single nozzle and multiple toolhead devices at the same time.

How is this done? Unfortunately, the Zaxe representative was not able to say more, so we’ll have to stay tuned for the September announcement.

Via Zaxe