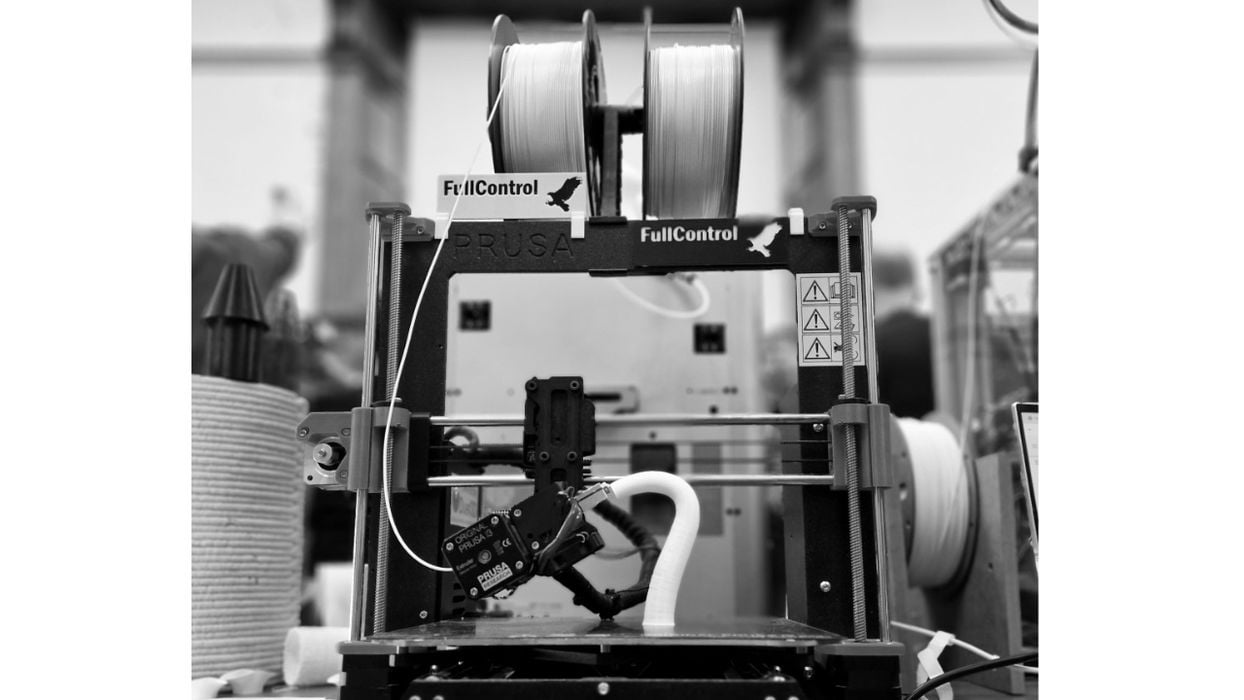

An open source project details how to add another axis to the Prusa MK3S 3D printer.

A fourth axis? What’s that all about?

FFF 3D printers have three directions of movement, referred to as X, Y and Z. This provides a perfectly suitable approach to print parts, but it does involve some constraints.

The most visible constraint is that the layers of a 3D model very often introduce overhangs. The 3D print job must then compensate with the use of support structures, which as a side effect introduces quality issues and adds time and cost.

To overcome that issue, some have developed five axis 3D printers. The idea is to simply rotate the print around to “invert” the overhang while that section is printed. Those 5-axis system can almost always print without support structures.

The problem is that 5-axis 3D printers are quite expensive and extraordinarily complex. Computing the toolpaths is far more challenging and requires more sophisticated software algorithms than are typically found in basic 3D print job slicers.

The project mentioned here, ”Open-Source 4-Axis Printer-Conversion and FullControl Toolpath Generation” describes a kind of compromise solution. Instead of five axes of motion, there are four. This wouldn’t be as good as five axes, but still useful. The project explains:

“A lot of 5-axis R&D can be done much more simply in 4-axis (e.g. procedures for collision avoidance/detection; e.g. toolpath design methods; e.g. testing gear ratios for rotation axes) and many object don’t need the 5th axis if they have a degree of directionality (e.g. angle brackets; e.g. elbow pipes).”

The project isn’t as complex as you might expect, as there seems to be only a few brackets to 3D print, a stepper motor and replacement of the electronics board.

The result is a system in which the hot end can tip left or right, when viewed from the front. Check the image at top to see how this works.

The stock Prusa board is replaced with a powerful Duet 3 board, with firmware provided from the repository.

For slicing software you cannot use standard tools. Instead, the project recommends using FullControl.xyz, which is something we looked at a while ago.

FullControl understands non-planar 3D printing, which is what is going to happen with this modified 3D printer.

This might be a project best suited for those with some experience building 3D printers. If you manage to get through the process, you will have one of the most unique desktop 3D printers available.

Via Google Colab (Hat tip to Tuan)