Sculpteo introduced a feature that is quite unusual.

The BASF-owned, France-based 3D print & manufacturing service has been around for many years. They accept submitted 3D models and can print them in quantity on a variety of equipment in many different materials.

That’s what most 3D print services do, so that’s not a surprise. But recently they announced a new feature they call “Insert Placing”.

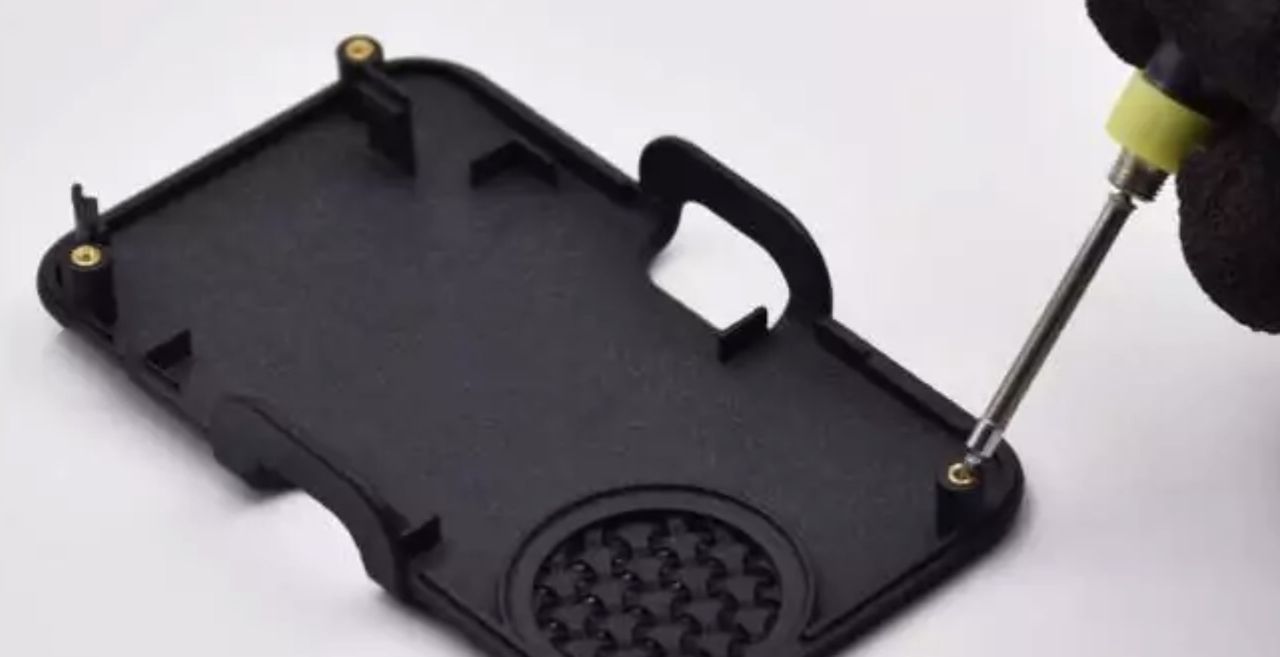

What’s an “insert”? It’s when you pause a 3D print job and take that opportunity to “insert” something. Typically an insert would be a nut or bolt, or other fastener. After insertion the print job resumes, covering over the inserted component.

In the end you get a 3D printed part equipped with, say, embedded nuts ready to receive bolts.

It’s a very common practice among 3D printer operators, and I’ve done this myself many times.

But can a 3D print service do this?

I’ve never heard of this being done, but I am sure some provide a service for insertions. Most do not, and service users cannot get parts printed with inserts.

3D printer operators wouldn’t think this is much of an issue because they can just learn how to do it themselves. However, users of professional 3D print services like Sculpteo use them often because they do not have the ability to print parts themselves. Additionally they may not have access to the high-end 3D print processes offered by Sculpteo.

Sculpteo’s new “insert service” provides a means to use those high-end 3D printers with inserts. Sculpteo explains how it works:

“Utilizing our Insert Placing service is simple and seamless. When you place an order for parts that require inserts, just contact our expert team. They’ll work with you to determine the correct type of inserts for your specific application. You can also check out our Technical Specifications page to learn about insert housing specifications.

Once your parts are ready for production, our skilled technicians will 3D print your parts, followed by the placement of inserts or screws into your parts, ensuring precision and accuracy. Then, your parts will be promptly shipped to you and ready for immediate assembly.”

Sculpteo explained that the insert service works with three of their 3D print technologies: SLS, HP’s MJF and Stratasys’ FDM. Each of these provides a variety of different materials that can be used in a wide range of applications.

This is an interesting development that could drive more business towards Sculpteo, and enable easy access to stronger print processes for insert-enabled parts.

Via Sculpteo