A new paper explores the idea of Manufacturing as a Service (MaaS).

With the emergence of 3D printing technology it has become easier to produce products on demand. The idea of pressing a button and receiving an object is indeed feasible, and there are multiple models that can make use of this paradigm.

One is digital inventory, where a library of spare parts awaits printing when required. In this scenario a worker requiring a spare part triggers the printing process. This is a highly efficient process that eliminates the need for expensive physical warehouses.

Another approach is consumer purchasing, where a buyer triggers the production of a part that is later delivered.

There have been implementations of this process in varying forms over the years by different parties, but now researchers have investigated the concept from a scientific point of view.

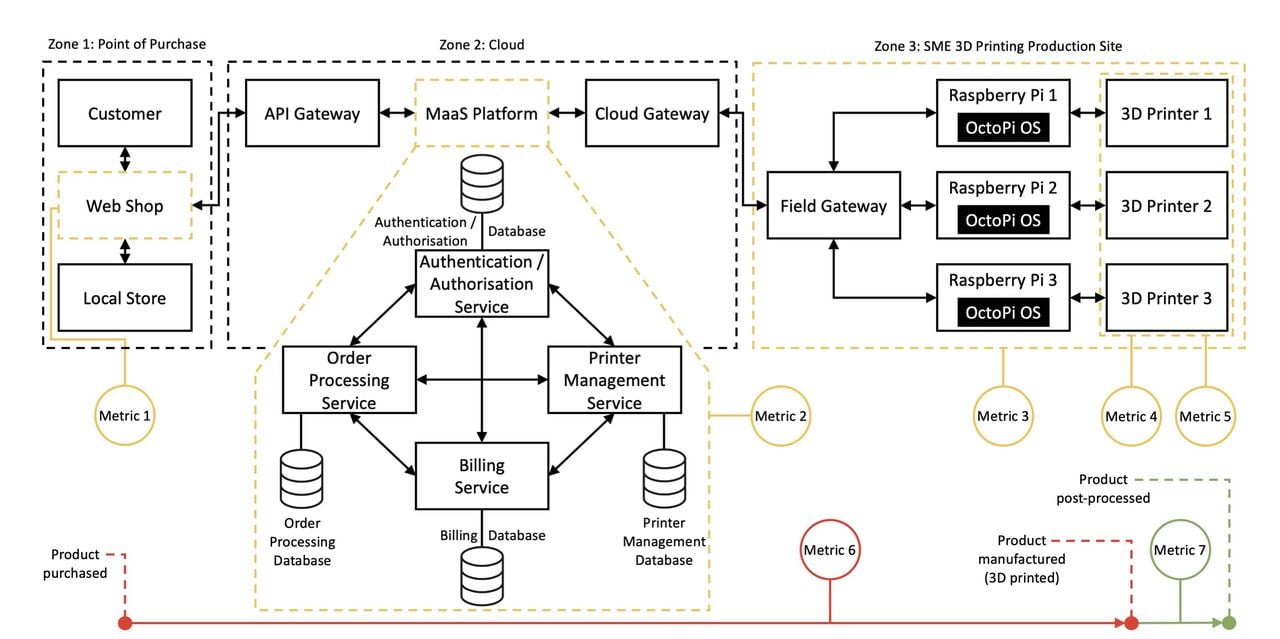

They developed a conceptual model of the process, seen above. It seems straightforward, but it’s actually quite a bit more complex than you’d think. Consider their test-bed implementation diagram at top, where they built all the elements required to deploy a working system.

In the diagram you’ll notice the 3D printers on the right, driven by Octoprint servers on Raspberry Pi devices. On the left is a web shop where buyers can browse and select products.

In the center is a cloud system architecture that includes order management, authentication, billing and printer dispatch functions.

The really interesting part is the “metrics”, which are shown as circles on the diagram. These represent the key points of measurement for the system, as defined by the researchers. These include:

- Metric 1 – Operating Costs (Web Shop)

- refers to the monetary cost of operating a web shop.

- Metric 2 – Operating Costs (MaaS Platform) refers to the monetary cost of operating the MaaS platform in the cloud.

- Metric 3 – Energy Consumption

- refers to the energy cost of operating the SME 3D printing production site including all devices.

- Metric 4 – Printing Time

- refers to the time it takes a 3D printer to print a given product.

- Metric 5 – Material Usage

- refers to the material cost (amount or quantity of 3D filament used) to print a given product.

- Metric 6 – Processing Time

- refers to the lead time it takes to manufacture a purchased product on a 3D printer, starting when the customer purchases the product (Product pur- chased) and ending when the printer completes the 3D printing process (Product manufactured or 3D printed).

- Metric 7 – Post-Production Labour Costs refers to the labour costs associated with poten- tial post-production steps (e.g., cleaning, polish- ing, grinding, painting, etc.).

They then identified the stakeholders in this scenario, including:

- Web shop operator

- Buyer

- CAD designer

- Cloud operator

- Printer operator

Each stakeholder should take a portion of the purchase price to provide their part of the overall function. Note that each stakeholder could be a completely separate entity, connected only by the electronic protocols.

Variations of this concept have been implemented by some of the manufacturing networks. However, the researchers propose that this concept should be used on a much wider scale in order to take full advantage of the concept. Those benefits could include a far more resilient and responsive supply chain, as well as optimized use of equipment.

Companies like Xometry, Protolabs, Shapeways and others have implementations of this concept, but I believe the researchers really believe that ALL manufacturing should work in this manner. If that’s the case, then we would have a very tightly integrated manufacturing world where companies could reach out into the MaaS network and very quickly produce parts.

I’d call it Interoperable Manufacturing.

Via ArXiv (PDF)