An interesting development has occurred in the automotive sector that could drive adoption of 3D printing.

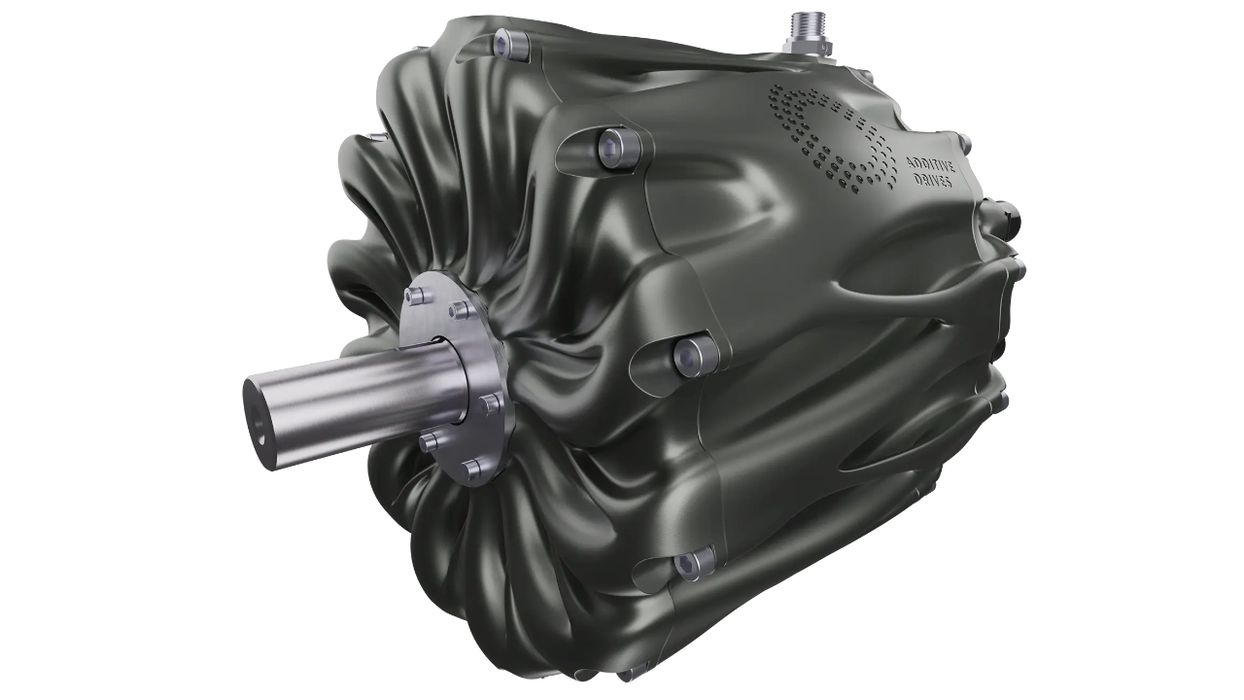

EV Tech Insider’s interview with Additive Drives, a German startup 3D printing EV motors, reveals how 3D printing can be used to great advantage in the automotive industry.

What’s the big deal? It seems that Additive Drives has discovered how to properly leverage the near-complete design freedom provide by 3D print technology. They have designed unique geometries that provide the same or better function with less weight. In the interview, they explain:

“There have already been attempts to print complete motors in the past, all of which failed due to the high costs and, in some cases, poorer efficiency than a conventional electric motor. We differentiate between the sheet metal packages, conductor structures, and the housing. For example, it can make sense to print a housing because a special geometry helps to optimize cooling. Aluminum alloys are usually used here. The material development of copper and aluminum is now so advanced that the printed materials can have better material properties than, for example, a drawn copper wire, as cold forming no longer takes place.”

They’ve used this to produce electric motors that have 45% higher power densities than motors made with conventional methods.

They’ve also been able to reduce AC losses by 50%, and also save energy by up to 50%.

These statistics might not mean much until you realize how much more efficient EVs could be. In fact, Additive Drives’ motors are approaching levels that would enable financially feasible electric aviation.

For now the company is producing custom motors for specific projects and applications, such as Formula E, and they’re working with some large EV manufacturers on future products.

This is extremely interesting to me because it is a signal that could trigger a significant shift in the EV industry.

Readers may recall that only a few years few major industries adopted additive manufacturing. One of them was aviation. That all changed when GE introduced a new engine with a significant proportion of 3D printed parts. The engine was lighter, easier to maintain and offered other benefits.

That triggered the aerospace industry to take a hard look at 3D print technology and see how it could be leveraged for other products and components. Since then there has been quite an explosion of 3D printed items in the aerospace industry, as each competitor tries to keep up with the technological developments.

Could the designs from Additive Drives trigger a similar explosion in the EV space? From the specifications, it may even flow into the aerospace sector as well.

We just might be on the verge of a new period of additive manufacturing expansion.

Via EV Tech Insider and Additive Drives