The importance of support structures, or rather the lack of them, was revealed in a visit with Velo3D.

Velo3D is one of many well-known metal 3D printer manufacturers. Like most, they use the standard LPBF process in which a laser selectively melts metal powder, layer by layer.

But there’s one difference with Velo3D’s approach: they have a very interesting design for their recoater. This is the printer component that spreads out a fresh metal powder for fusing the next layer of a print.

Most systems use a simple blade to even out the powder, which must lie absolutely flat to ensure the laser dot is focused. However, these rigid blades can strike the metal that was fused in the prior layer, shaking up the model. In extreme cases this effect can distort the print from the impact. Because of this most LPBF metal 3D print jobs require copious amounts of support material to ensure the recoater blade doesn’t affect the print.

Velo3D’s recoater is not like this, and it provides a very light touch at most. The result is that in most jobs printed on Velo3D equipment very few support structures are required, and even then they can be quite a bit lighter than typical supports.

This saves money because less powder is used: there’s less dedicated to the support structures. It also significantly saves money during post processing because the (usually) manual labor required to cut off the supports diminishes greatly.

But there’s another benefit that I saw first hand when looking at a series of metal prints made by Velo3D.

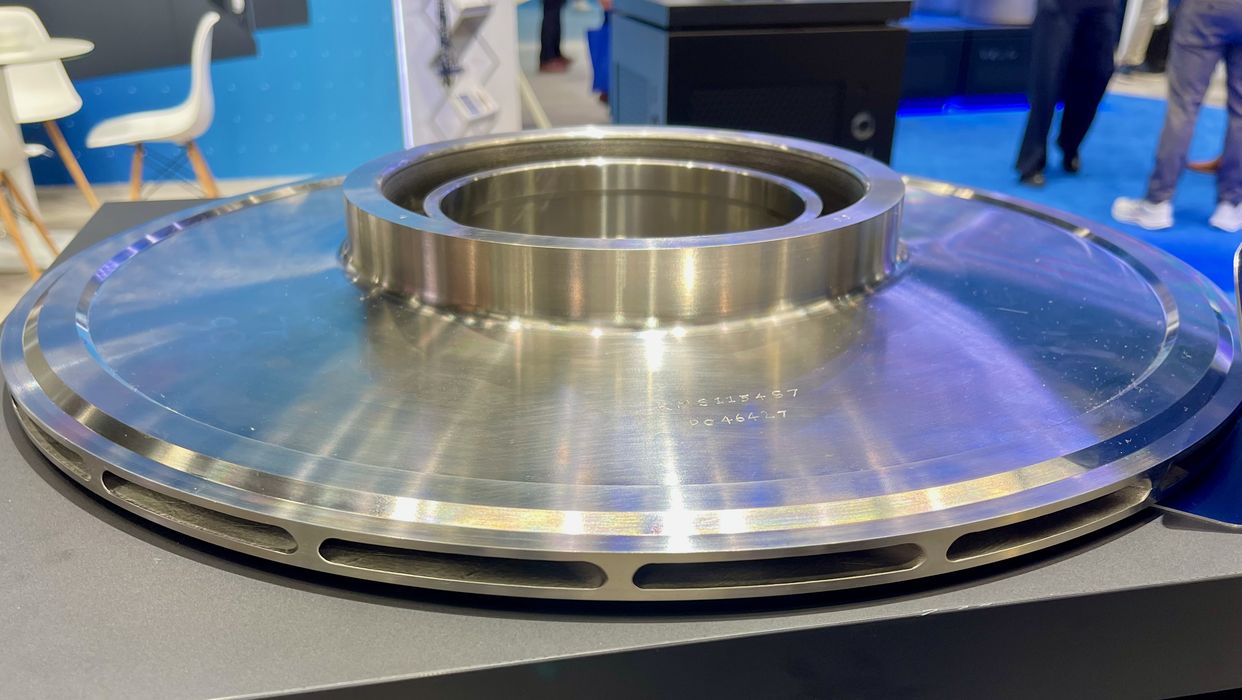

At top we can see what seems to be a straightforward metal part. However, a look closer reveals that there is a complex interior with low angles. Velo3D was able to 3D print this item as a single part, which would normally have been done in two parts and then assembled.

How did they achieve this? Velo3D representatives explained that the did use some support inside the part, but it was “light”. So light that the post processing basically involved “sweeping” it out.

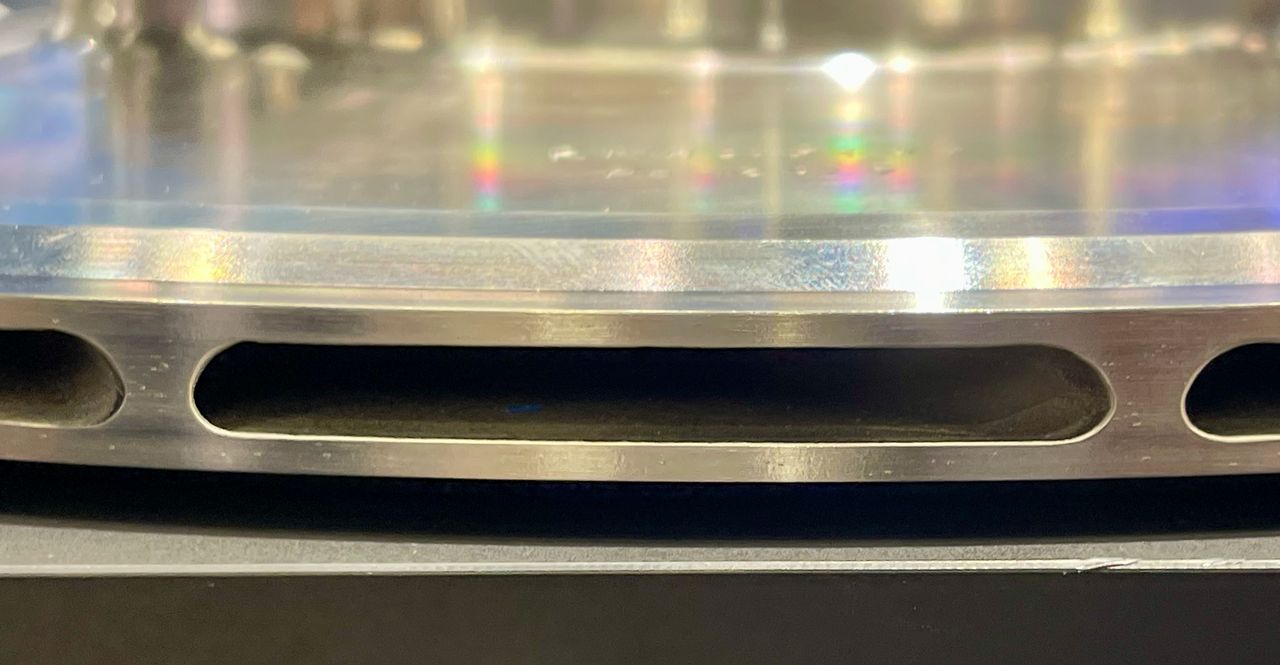

Here’s another example. This is a closeup of a flow control unit for the oil and gas industry. If you look inside you’ll see quite a bit of detail and plenty of overhangs. Somehow Velo3D was able to easily 3D print this metal object in one piece without the need for significant supports.

This component is even more impressive if you look at the top, which shows considerable fine detail.

Here’s a final example of something that is extraordinarily very challenging to print: a rocket engine combustion chamber, made in a copper material. While it might appear to be a smooth cylinder from the outside, there are a myriad of tiny channels inside.

In this view they’ve cut away a portion of the skin to show what’s going on inside. Imagine dealing with complex rigid supports inside such a structure.

These and plenty of other examples show what’s possible when you don’t have to worry so much about support structures; new geometries can be unlocked and complex components can be collapsed into, perhaps only a single part.

Via Velo3D