The CDC has issued a lengthy guide for 3D print safety, something that all 3D printers operators should read.

Safety has been a big concern at this publication, as it has largely been ignored by participants and manufacturers for many years. Only recently has safety risen as a priority, and we have slowly started to see safety features beginning to appear in device designs and material compositions.

However, for those new to the technology it is not easy to determine the best safety practices. Sellers of 3D printers almost never mentions safety practices or features (because sometimes there are none), and this can leave the operator without enough information to safely operate their equipment.

Now the CDC itself has issued a formal guide for the technology, entitled, “Approaches to Safe 3D Printing: A Guide for Makerspace Users, Schools, Libraries, and Small Businesses”.

This is not a small report, it’s forty pages long, and includes a vast amount of information and advice. It’s also designed to be relatively easy to read, and anyone using equipment should be able to make their way through the material and take appropriate actions.

The guide provides a bit of an introduction to the most common 3D print technologies so that the reader understands where the safety concerns originate.

Many Fabbaloo readers will be familiar with the basics of 3D print safety: FFF devices generate potentially toxic emissions, requiring ventilation; 3D printer resin is toxic and requires special handling and also ventilation.

But the CDC report goes much deeper and provides detailed lists of concerns for the entire 3D print workflow, not just the printing itself. This is a much more realistic view of safety concerns because it addresses what will actually occur in a workshop, school or makerspace.

I learned several new things while reviewing the report, including:

- Some solvents used for cleaning 3D printers can be hazardous

- Post printing activities pose some risks, including use of solvents and filaments with nano materials

- FFF materials can vary quite significantly in their emission

- Some solvents are flammable, but are commonly used

- Sodium hydroxide, used in some soluble-support solutions, is corrosive

- Mechanical components of 3D printers are able to catch loose clothing or hair

- Printer noise levels can exceed safety thresholds if a sufficient number of devices are operating

- Work surfaces and clothing can become contaminated

And there’s plenty more, it’s a very good read.

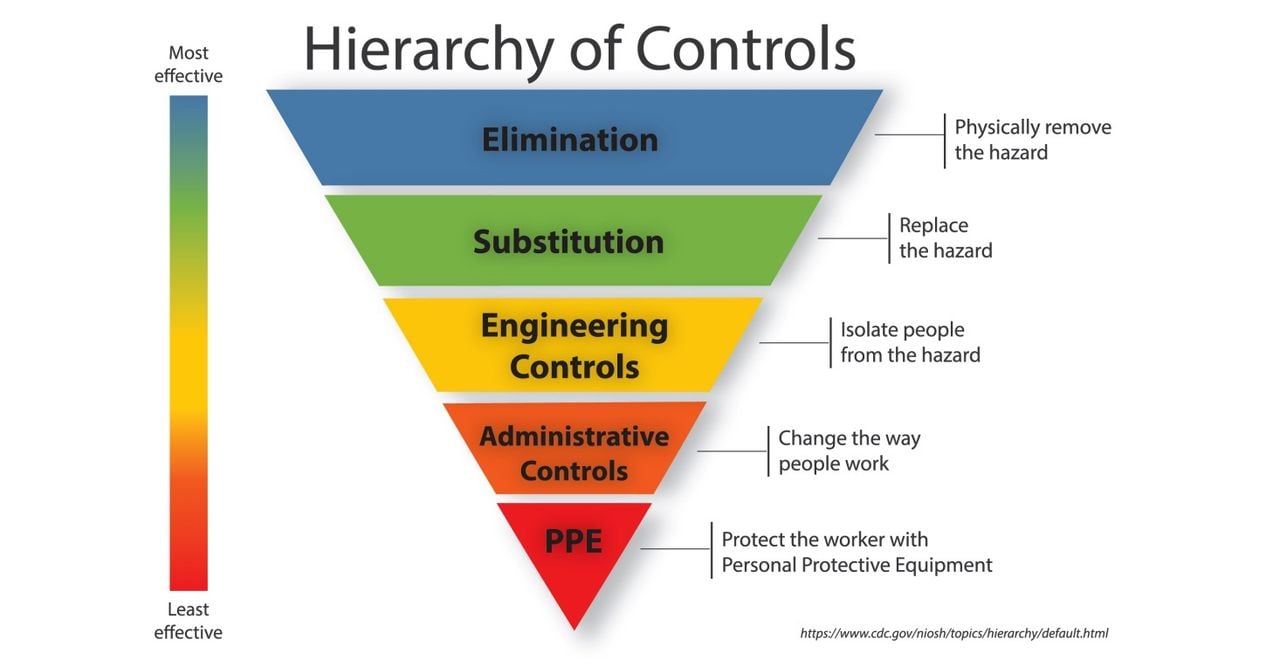

The guide also provides advice on how to set up a risk management plan, including use of the standard hierarchy of controls shown here.

One of the most interesting findings was a specially designed cooling vent for FFF toolheads. Normally these are used to blow cold air on freshly extruded material to freeze it as soon as possible, but they also tend to blow emissions all over the work area. The redesigned ducting was able to reduce emissions by a startling 98%!

This ducting was developed as part of a research paper back in 2020 for a MakerBot Replicator+, so it is not suitable for today’s equipment. However, the fact that it is possible to design such a duct is important — but I have yet to see any 3D printer manufacturer make use of that approach.

The guide provides a number of similar examples of ways to reduce risks, and I am quite surprised they have not been taken up by 3D printer manufacturers, particularly by those marketing directly to schools.

This report is, by far, the most comprehensive and useful safety document yet produced for 3D print operations. I strongly recommend that anyone operating 3D printers spend the time to read through the material and follow its advice.

Via CDC (PDF)