I had a chat with Replique, a German additive manufacturing network.

Manufacturing networks are of great use to small and medium-sized business that cannot operate their own manufacturing operations. This is particularly true for additive manufacturing, where peculiar and rare skills are usually required for successful operation. Replique links customers requiring prints to professional operators who can get the job done.

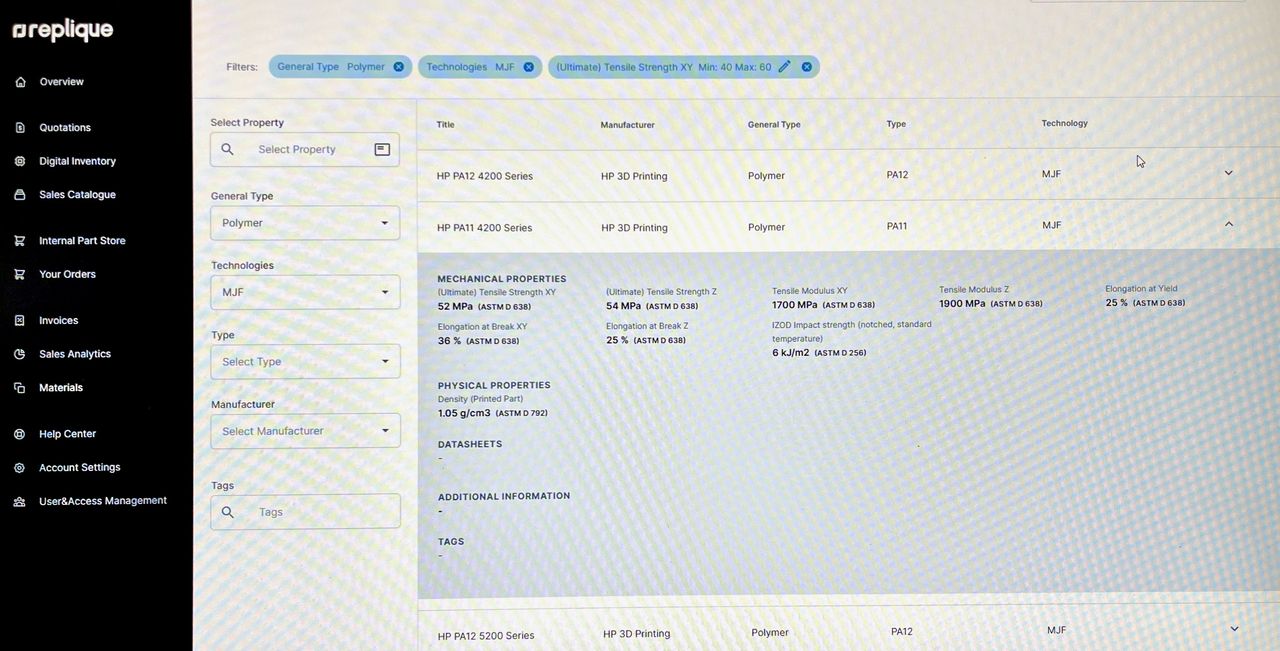

One of the latest features implemented in Replique’s system is a new materials database. The idea here is to help engineers using their system to select the best material for their application.

The material database includes the engineering properties for a wide range of materials, such as fire resistance, thermal properties, strength, and much more. Engineers can browse and select the best materials based on this information. The database also includes certifications, which can be used as filters.

Engineers can choose the properties they require, perhaps several, and the system then provides a list of not only material options, but also recommendations for the production process.

I asked Replique how they could possibly maintain this database, as there are countless mateirals and they’re changing all the time. They explained that they have data feeds from a series of chemical companies that have developed the materials. In this way they can keep their database up to date at all times.

Once selected, the system can then filter down the providers to those that use the selected materials, simplifying the process considerably.

The use of certifications also enhances the trust of engineers, and should make their work more efficient: pick the correct material right away, and don’t waste efforts on other materials.

At this time the database includes only polymer materials, but Replique’s intent is to add a metal materials database at a future time.

Improvements such as this new materials database are important to the 3D print industry, as they help remove friction encountered when using the technology.

Less friction, more printing!

Via Replique