We had a chat with AI Build, and learned the latest from the additive manufacturing software company.

The software they produce is “AiSync”, a very sophisticated toolpath generator (or “slicer”) for additive manufacturing projects. But it’s more than just that: it also controls the entire 3D printing process, including monitoring, control, measurement and optimization.

Their target market is manufacturers using additive manufacturing, where efficiency is key. This is sometimes elusive for manufacturers new to the technology, as it is increasingly challenging to hire highly experienced additive engineers who would tune the print jobs for maximum efficiency. That issue is even more problematic as we have a wave of very new technologies that are quite different.

AI Build hopes to address those issues by making the software figure out the difficult details of 3D printing for manufacturers. They explain:

“Our goal is to enable Additive Manufacturing to scale and realize its global potential.

Through advanced automation, slow and error-prone manufacturing becomes fast, predictable and repeatable.

Increased 3D printing capability through one simple UI that manages even the most advanced toolpaths across all 3D printers in any location.”

One of the key features they’ve recently introduced is natural language processing. They call it “talk to AiSync”, and that’s precisely what you do. Well, you type instead of speaking, but you get the idea.

You can ask AiSync to prepare a job with emphasis on strength, or other attributes, and it will do so. This short video demonstrates how it works:

How has AI Build achieved this? It turns out, according to their representatives, that they’ve used a special GPT4 AI model that’s been trained in the 3D print domain. The model can accept input that’s very specific, or quite general and respond appropriately. It can even handle conversations in multiple languages.

AI Build tells us that there are “lots of users testing this feature”, and that many are quite excited and have asked for more operators to be added to the tool.

In addition, they were “quickly accustomed” to using the software. That’s a very good signal, as it jives with AI Build’s goal of simplifying additive manufacturing. It suggests that a manufacturer entering the AM world might be able to get very good results with less need for rare human expertise.

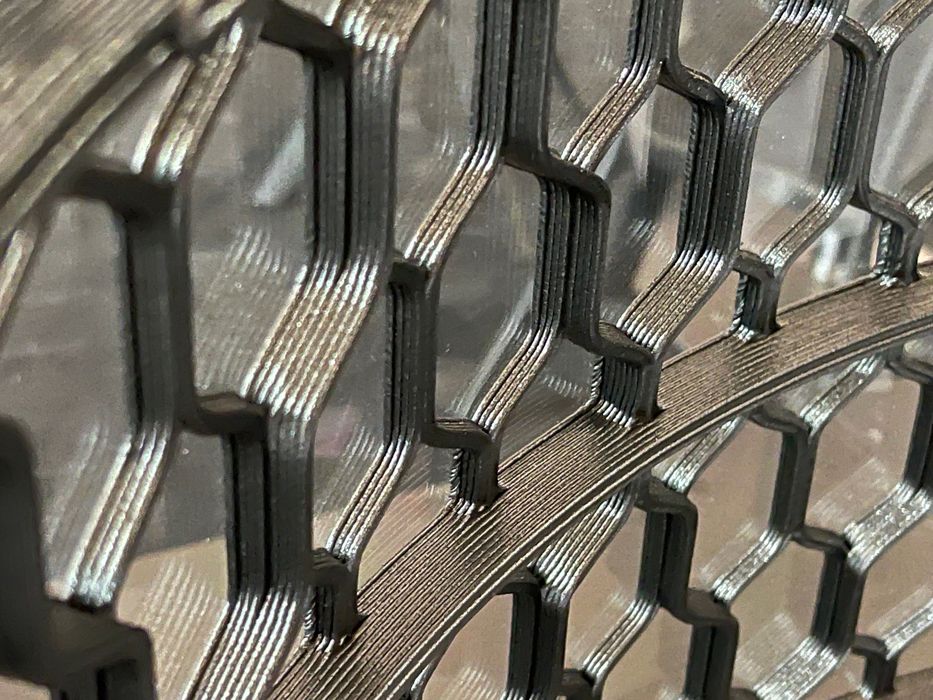

Does it work? Consider this example, a robot gripper printed using AiSync:

AI Build explained that this 9kg gripper was printed in nine hours, and is one of many made by their customers. Typically they see 25-50% reduction in operations cost by using AiSync, likely due to less need for iterative prints to dial in the result.

They also said the parts are typically 20% less weight, are made with 50% less lead time, and reduce CO2 emissions by around 60%. That’s all good news and something most AM manufacturers would benefit from.

AI Build representatives told us that the system gets smarter every day, as more jobs pour through the system. It can now even optimize GCODE if required. However, it’s apparently still considered a beta feature that’s not generally available.

It also sounds like they are interested in developing software for something called “MAT”, or “Multi Additive Technologies”. This concept involves one machine, but multiple making processes. This could, for example, include not only FFF, but also ceramic extrusion, pellets, CNC milling and even rotocasting.

AI Build is positioned well for the coming AI avalanche, as their system can now take advantage of the constantly increasing AI capabilities. Their vision is to make AiSync the “smart expert on staff” for manufacturers, and they seem to be taking the correct steps towards that goal.

Via AI Build