Stratasys unveiled a new FDM 3D printer targeted at industrial buyers.

The new F3300 is similar to prior machines, yet completely different. We were told the machine was under development for lengthy six years, and now it’s finally been released.

Evidently the Stratasys engineers were asked to start with a blank sheet and build the “best 3D printer possible”. Of course they leveraged the experience and technology from earlier machines, but this device is quite different.

For starters, it’s fast.

Stratasys said it can peak out at 500mm/s, and accelerate at 1.2g. This is done with linear motors that can also slide non-print moves at up to 1500mm/s.

Many filament 3D printers these days are billed as “high speed”, and most of them accomplish that through some form of vibration compensation firmware and accelerometers. I asked whether the F3300 does this, and was told it actually does not. The machine is so massive and robustly built there isn’t any significant vibration!

Stratasys designed the machine to be as fully automated as possible. It is able to completely calibrate itself without operator intervention, which should make it far easier to run.

The F3300’s build volume is quite generous at 600 x 600 x 800 mm, which is somewhat less than its counterpart, the 900mc. The two machines provide Stratasys customers with “big” and “fast” options.

One disappointing feature on the F3300 is the continued requirement for single-use print sheets. These are plastic sheets that are the print surface, held down by a vacuum pump. This is the same approach used on the old Fortus series, and while it works very well, it does represent another consumable. I would have liked a more reusable option, but Stratasys said they were unable to identify a print surface as effective.

For materials, the F3300 makes use of a number of engineering materials from the Stratasys catalog, including ASA, PC, Nylon 12CF and ULTEM 9085. These are provided on large 4100cc (about 4kg) spools.

The large spools are held in an on board “oven” that continually dries the material as seen here. The spools contain a chip that allows the F3300 to recognize the material and immediately implement the correct drying “recipe” for that spool. The dry bay can be heated as high as 120C, allowing for use of exotic materials.

The spools are “open” and not in canisters as were the Fortus materials. This means there is no need to recycle the empty canisters, simplifying operations.

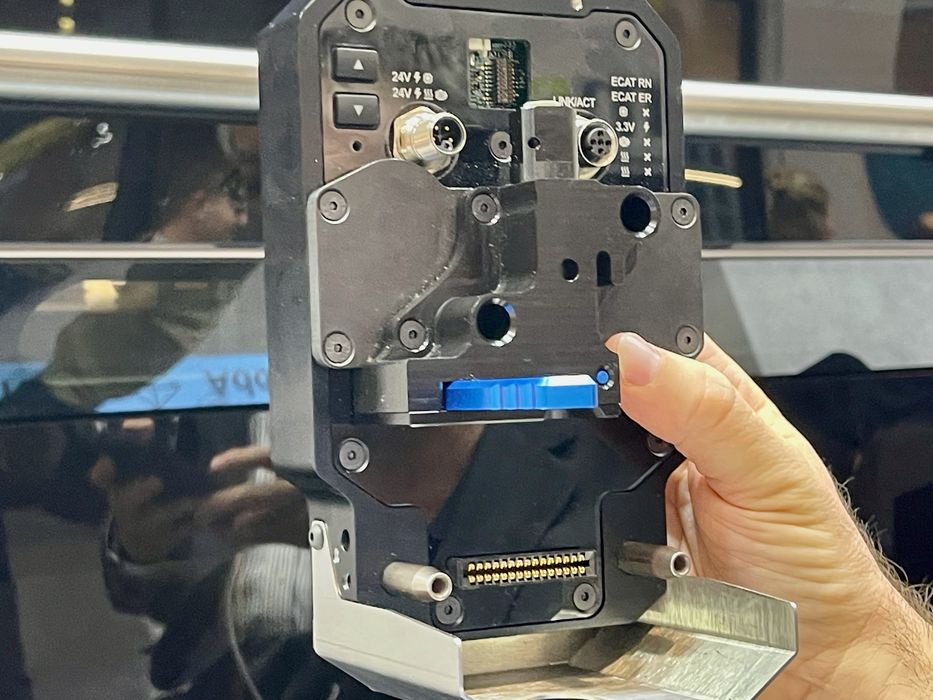

For extrusion, the F3300 has redundant toolheads, two for model material and two for soluble support material. This means that if one should fail, the other takes over and the job completes. I don’t believe I’ve seen this approach in other 3D printers, so it could be a very valuable feature.

The toolheads are changeable as well. Stratasys said the two nozzle options are 0.50mm and 0.75mm, and these should provide opportunities for print speed increases or fine detail. Note the long heat zone on the above image. Stratasys has already upgraded their GrabCAD software to handle the four printheads on the F3300.

While priced about the same as the 900mc, the F3300 should have lower operating costs due to the automation, materials and high speed printing. Stratasys said the machine should be less expensive to operate than previous Fortus machines.

The F3300 looks to be a powerful machine capable of producing very high quality, large-sized parts in reduced print times. It should be most appropriate for production facilities where certified materials and highly consistent production is required.

Via Stratasys