Charles R. Goulding and Preeti Sulibhavi discuss the current surge of labor strikes and explore how 3D printing could help companies manage rising labor costs during negotiations.

The summer of 2023 was a hot season for labor disputes in the US.

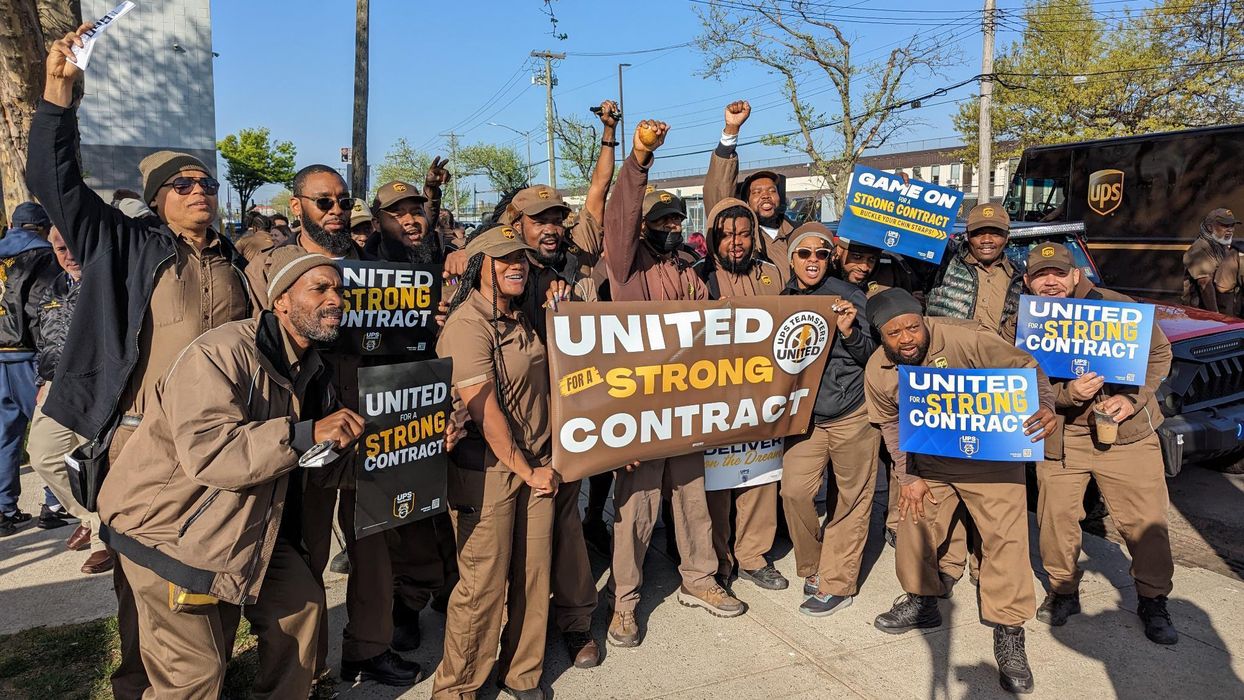

Wage negotiations with UPS, Hollywood and the Auto Workers unions have been the current hot topic.

When a business measurably increases a particular cost, it needs to find new revenue sources and or other cost reductions to maintain profitability. All three of the labor categories discussed above can use 3D printing to both increase revenue and reduce costs.

UPS

UPS settled their recent labor dispute by acceding to large wage increases.

Brian Newman, UPS’ Chief Financial Officer, discussed the cost of the increased labor costs which is estimated at US$500 million just for the remainder of 2023. According to Newman, “Now that we have our arms around what that cost will be, I can think about managing the P&L to drive margins.”

We have recently covered how UPS is one of the companies approved for and using out-of-sight licenses for the drones that they use for some remote deliveries. But the CFO went on to explain how UPS is looking for “new ways to be more efficient.” That includes more automation and leveraging more innovative technologies to reduce recurring issues such as packages ending up on the wrong delivery truck that must be re-sorted.

UPS has implemented several technological advancements to streamline and enhance various tasks within its operations. They have integrated Dexterity, Fortna, and Plus One Robotics for efficient sorting of small packages, improving safety and job satisfaction for employees. Additionally, they have adopted Pickle Robot’s unloading technologies to make trailer unloading less physically demanding for workers while ensuring better package care and reliability for customers.

To simplify demanding tasks, UPS has incorporated autonomous guided vehicles (AGV) from companies such as Dane Technologies, Geekplus, Locus Robotics, Crown Lift Trucks, and Toyota-Raymond. These AGVs facilitate the movement of small packages and irregular-sized shipments within UPS facilities, thereby improving safety and operational efficiency. Moreover, UPS has embraced digital technologies like Delivery Photo and Delivery Defense to enhance the security of global deliveries, effectively reducing fraud for customers.

These are some of the cost-cutting measures that UPS is taking and 3D printing can be one of them. Whether it is to fabricate drones or create replacement parts for UPS’ vast truck fleet, we have covered how 3D printing can be useful.

Hollywood

We have also covered the Hollywood actors’ and writers’ strikes. Now, with the SAF-AFTRA strikes resolved, audiences can now expect to see more new episodes of their favorite shows and movie production is resuming as well.

But Hollywood is struggling with production delays and supply chain issues that remain from the pandemic. One revenue-making measure that production studios can take. That would be branded items such as toys and accessories. Additional sales for related branded products are important revenue streams for movies that include Disney, Marvel and blockbusters like Barbie. We have covered how 3D printers can be used in creating toys and collectors’ items.

United Auto Workers

The United Auto Workers (UAW) strike involves the large labor forces of Ford, General Motors (GM) and Stellantis, known as the “Big Three”, and is affecting middle-class workers who make up the backbone of the US. Even President Biden joined the UAW strike this past September. A part of the auto workers’ demands includes concerns about a broader transition to electric vehicles (EVs), which is a problem for the Biden Administration’s new energy policies. Workers are concerned that transitioning away from internal combustion engines to EVs may cost them their jobs since EVs require 40 percent fewer people to manufacture them with no guarantee that EV factories will be unionized.

Here, 3D printing can be used to reduce costs. 3D printers can be used for replacement parts, reducing inventory as well. In addition, there can be new revenue streams for auto aftermarket accessories using 3D printing.

As of last week, all three automakers have reached tentative deals with the union. Ford was first to announce its tentative agreement with UAW on Wednesday, October 25, 2023, with Stellantis and GM following suit less than a week later.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

There is a way to include 3D printing in these three labor disputes. Whatever the outcome is, there will be a need for cost-cutting measures and increasing revenue streams. 3D printing can assist in improving the profitability of companies in these industries, especially when labor costs are higher.