After working with several high speed FFF desktop 3D printers lately, I think the industry is going to face a material crisis.

This year has all been about high speed FFF desktop 3D printers. For years these devices printed at speeds between 40-80mm/s, but today’s machines run at 150, 250, 500 or even 600 mm/s. That’s quite a bit faster, and prints complete far earlier than you might be accustomed.

This is all terrific news for 3D printer buyers, who now have increasing choices for high speed devices. Our informal survey from last week shows that the majority of leading desktop 3D printer manufacturers have at least one high speed machine on the market, with others no doubt to follow.

But after using several of these machines, it seems there’s going to an issue regarding materials.

Some of these machines require “high speed filament”, which is typically supplied by the manufacturer. And usually in one, and only one color.

In my testing I wondered whether “regular” filament would be usable at higher speeds. Generally, I found that good quality filament, such as Prusament, would be able to run at higher speeds, particularly if the extrusion temperature were tweaked a bit higher. However, these filaments would begin to fail at the highest print speeds.

Why would a filament fail? It’s because of the flow rate. At high print speeds, the extruder must deliver more material per second. This requires the material to soften very quickly as it briefly passes through the hot end. Higher speeds mean less time in the hot end.

The “high speed” filaments tend to have some chemical mix that enables them to soften a bit faster, making them more compatible with higher speed printing.

Now the fun starts.

I tested one machine with material supplied from the manufacturer, and it worked at extremely high speeds. This filament was NOT labeled as “high speed”. I attempted to use “normal” filament in the machine and found that it could run at the default high speed, but not at the extreme highest speed.

I tested another machine with material supplied from the manufacturer, and it works at a high speed that’s actually slower than the first machine’s “high speed”. But this filament was officially labeled as “high speed”.

Hold on, what’s going on here? How do we fit all this together to print properly?

First there’s the problem of high speed 3D printers: what does “high speed” actually mean?

In practice it seems that anything higher than about 80mm/s is being labeled as “high speed” by manufacturers. This is because some are desperate to catch up to the companies with very high print speeds. They also describe their machines as “high speed”.

In other words, “high speed” could mean a printer that runs at 120mm/s or one that runs at 600mm/s.

Let’s get back to filament.

I have personally seen:

- Filament that isn’t labelled as “high speed” work properly at extreme speeds (500mm/s)

- Normal filament that works at moderate high speeds (300mm/s)

- High speed filament labeled as “high speed” that works in lower high speeds (180mm/s)

- Normal filament that doesn’t work at moderate high speeds

If this seems confusing, it is.

Turn the clock ahead to next year when many people are or have upgraded their desktop FFF 3D printer to a “high speed” model. Now they have to buy some filament.

What would they buy? Should they purchase only “High Speed” filaments? Would these actually work on their specific device at its highest speed? How could they possibly know? Should they buy good quality filaments and hope they work at higher speeds? What if the desired color isn’t available in “high speed”?

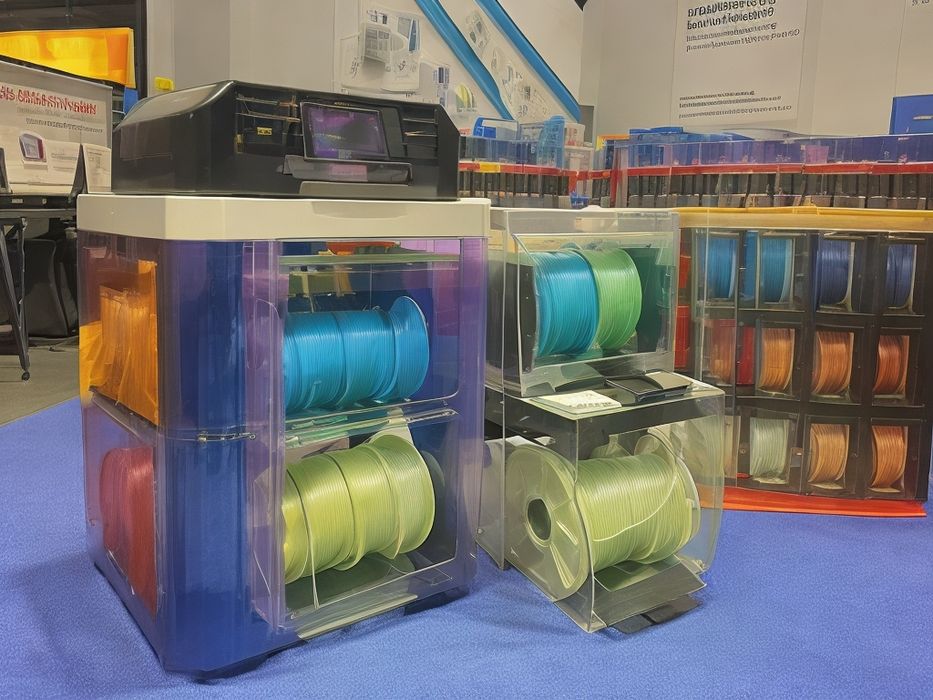

What do they do with their existing collection of “normal” filaments? Throw out all the spools? Print them at slow speeds on their high speed device? What if some of it actually works at high speeds? Do they have to test all of it?

I think the industry will ultimately have to devise some way of qualifying filaments so that everyone can know their high speed capabilities.

Could it be as simple as having both machines and filaments be “speed rated”? As in, a machine might be spec’d at 500mm/s and you would buy filament that’s rated for 500mm/s.

While that seems like the obvious approach, I’m not sure it would work in practice. If a machine is billed as being 500mm/s, is it really that fast? I know that many of these high speed machines have default print speeds that are somewhat less than their theoretical maximum print speed. You might end up buying a filament that’s “too good” for the machine.

This issue will also plague filament suppliers, who now should consider whether to label their products so that buyers know what they are getting. It’s no longer sufficient to say the filament is “1.75mm, matte red, 750g” because the buyer also now has to know whether the spool can be printed at high speeds on their new equipment.

Another approach that might be the most straightforward is to simply change ALL filament to be “high speed” and be done with it. That is unlikely to happen, given the massive inventory of today’s filament suppliers.

The next year is going to be quite a mess in terms of 3D print materials.