Our hands-on review of the Flashforge Adventurer 4 Pro concludes with a look at its specialized software, print results and final thoughts.

This is part three of a three part series, please read parts one and two.

Flashforge Adventurer 4 Pro Software

Most 3D printers simply use one of the three commonly available slicing systems, either Ultimaker Cura, PrusaSlicer or Simplify3D. However, the Adventurer 4 Pro uses none of these. Instead it uses a custom system called “FlashPrint”.

I downloaded the current version of Flashforge FlashPrint 5 software from the company’s website.

It seems to be a very standard slicer and similar to other vendor’s slicing software. If you’ve used any other slicing software, you’ll very quickly recognize all the parameters and process.

I didn’t encounter anything particularly different or notable in FlashPrint after using it to slice a few of my own 3D models.

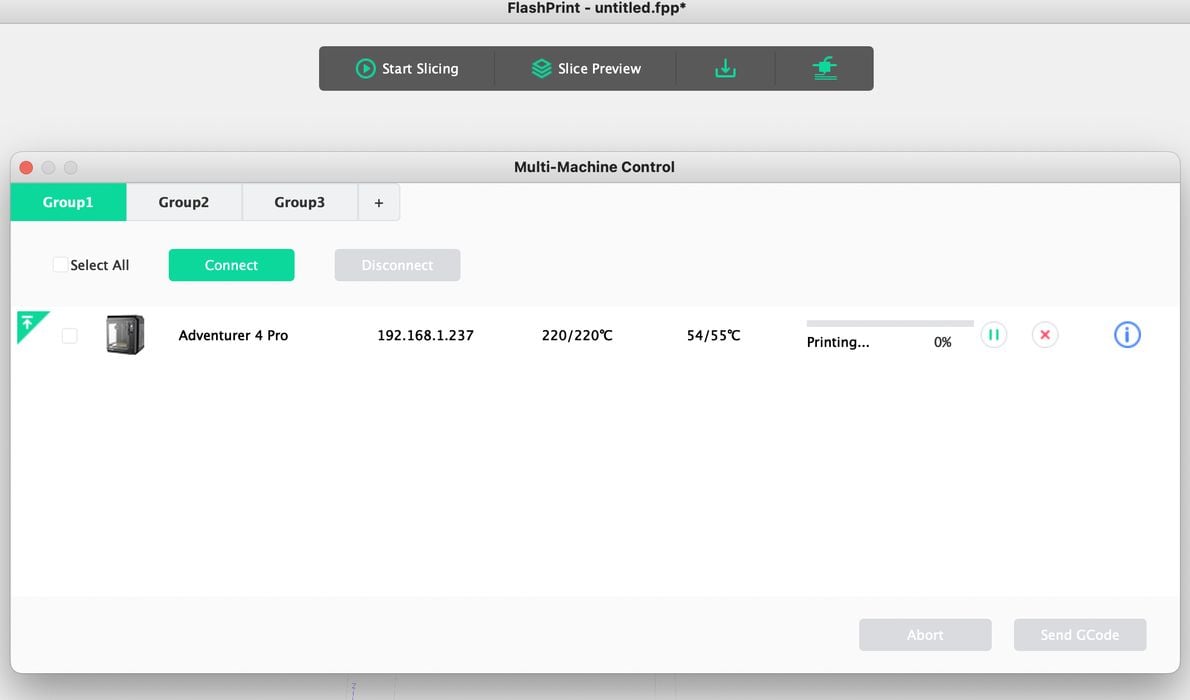

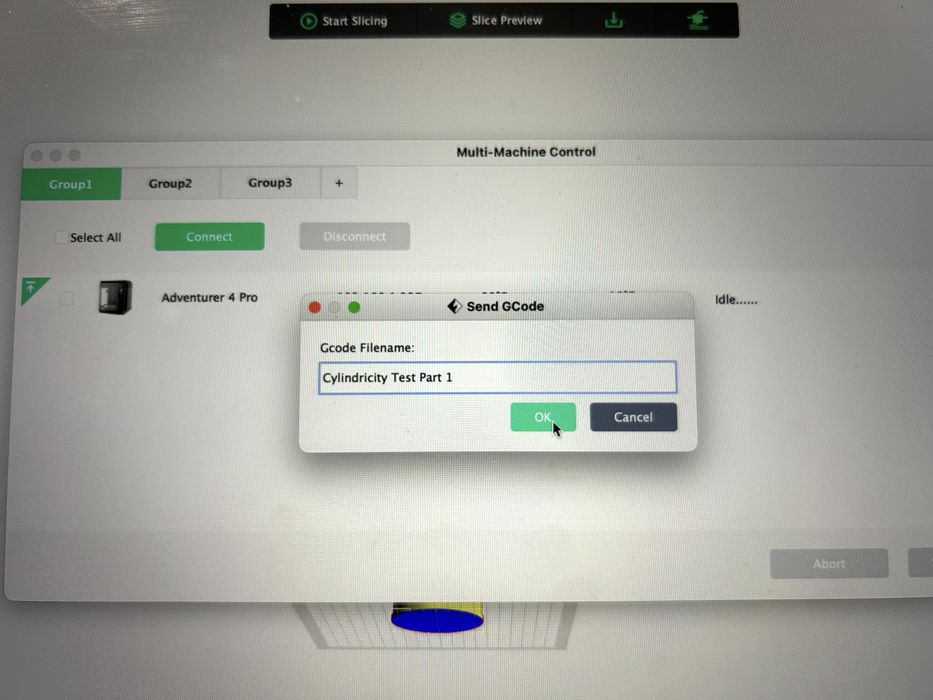

There is one big difference, however: WiFi. FlashPrint is able to connect wirelessly to the Adventurer 4 Pro and can start, stop and monitor 3D print jobs.

Sending prints to the Adventurer 4 Pro WiFi works well and I found no issues doing so. In fact, it is actually quite convenient as you don’t have to run over to the device with a USB stick, so it’s actually faster to use, particularly if the Adventurer 4 Pro is located in another room.

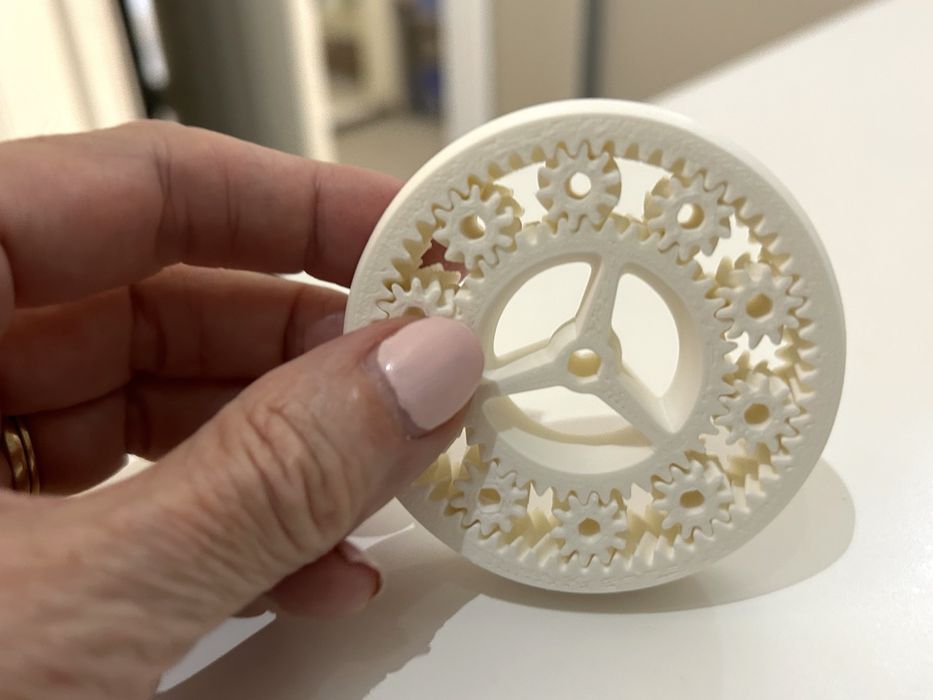

One of my test prints was the classic “Planetary Gears” 3D model. This object, if printed properly, will easily turn all the gears.

My first attempt didn’t work, as the gears were fused solid and there was no rotation possible. I guessed that this job had too much flow rate: the excess material would expand the extrusions and they would fuse together.

For the second attempt I needed to adjusted the flow rate. However, as happens frequently when using different slicing software, the terminology changes. In FlashPrint it’s called “Extrusion Ratio”. I’ve also see other software call it “Extrusion Multiplier”. The default value for the extrusion ratio turned out to be 109%, which seemed high. I adjusted it to 100%, and was able to 3D print a Planetary Gear model that worked perfectly right off the print bed. Importantly, this was printed in ABS, not PLA, making it an even more impressive print.

Flashforge Adventurer 4 Pro Print Results

The print results of my first test prints were very good except, aside from the first few layers. These were squished because of my initial Z-gap misalignment. But once calibrated correctly, print results were always very good.

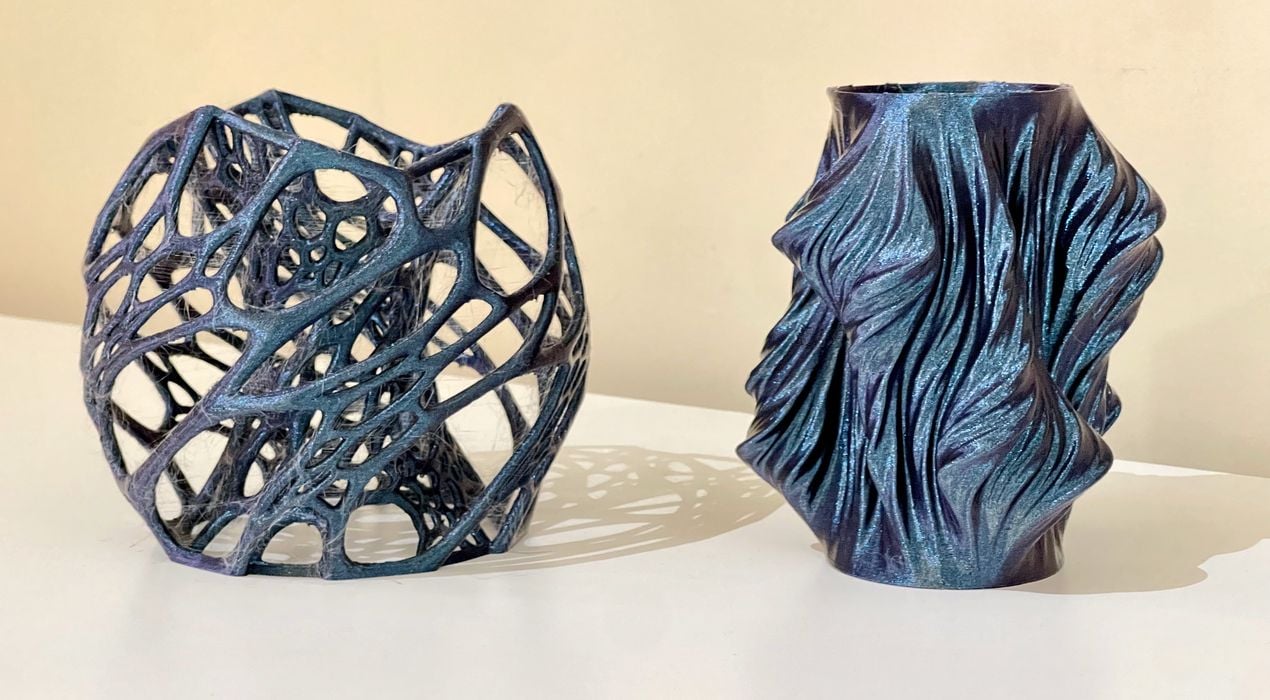

The Burnt Titanium material did have a slight tendency to string, as you can see in this closeup image. This isn’t a big issue, as the strings can be quickly removed with a heat gun, or perhaps more fine tuning of the retraction settings.

Generally, print results were very good on all prints. We did not notice any particular quality issues on any of the prints we ran on the Adventurer 4 Pro.

Larger prints didn’t seem to have a problem. We printed a number of tall vases and similar objects without issue. We were even able to successfully print this very cute articulated Tardigrade 3D model with no problems, as its arms moved freely.

The first couple of ABS test prints had none of typical issues known with ABS. No warping or lifting issues were seen, and I concluded that the Adventurer 4 Pro is quite a good machine for printing warpy materials like ABS or ASA. It would probably work very well for PA11 and PA12, assuming the adhesion issues could be resolved.

Flashforge Adventurer 4 Pro Final Thoughts

In spite of the several challenges I had, I believe the Adventurer 4 Pro is a very good desktop 3D printer.

Most of my frustrations ended up being user error as opposed to something wrong with the printer itself, so don’t count out the device based on those experiences.

Priced at around US$900, the Adventurer 4 Pro 3D printer is good value for the money, and produces very good mechanical parts using both PLA and ABS materials — and likely others as well.

I found it to be an easy-to-use 3D printer with a professional feel and output. It would look good in any office or professional environment, and produce similarly good output.

FLASHFORGE

ADVENTURER 4 PRO 3D PRINTER

★ BEGINNER 8/10

★ ENTHUSIAST 9/10

★ PRODUCTION 9/10

BEST FEATURES

✔︎ Print speed

✔︎ Easy setup

✔︎ Print quality

QUESTIONS

✖︎ Hardened profiles

✖︎ Missing letters

✖︎ Missing glue stick

This is part three of a three part series, please read parts one and two.

Via Flashforge

Thank you for the article on the Flashforge Adventurer 4 Pro. I’d like to point out that the increase in speed was due in large part to the integration of Ulendo Vibration Compensation (VC) software. Ulendo VC was able to increase the standard speed from 50mm/sec to 200mm/sec and increase acceleration from 2,000 mm/sec to 10,000mm/sec. If you provide your email address I can send you the press release detailing the integration.