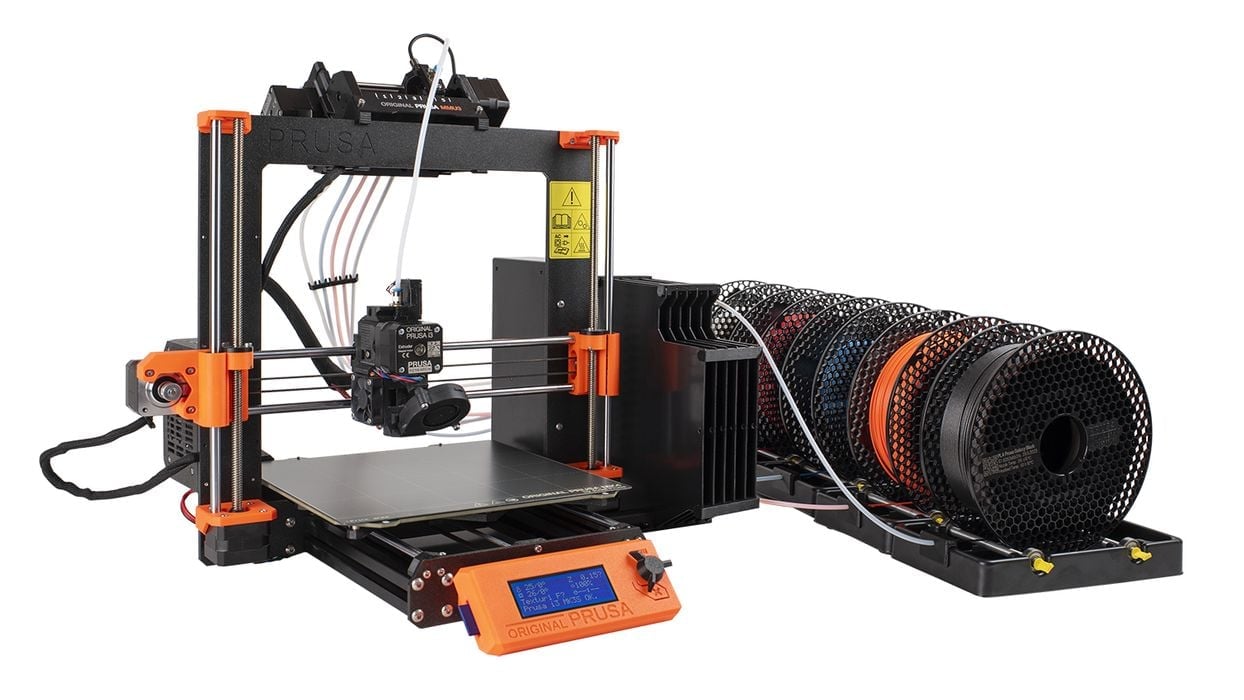

Prusa Research is now shipping their MMU3 unit, and has provided more details on including interesting upgrades and firmware changes.

The MMU, or multi-material unit, is a hardware attachment for certain Prusa 3D printers. It’s basically a filament swapping device, where filaments can be retracted from the extruder during printing and replaced with another.

This enables a print job to use up to five different colors, theoretically without human intervention.

The MMU first emerged several years ago, but was quickly replaced with the MMU2S, which has been the current version until this week with the official release and shipment of the MMU3.

The MMU2 was a highly problematic device and many operators had extreme challenges getting it to work correctly. Problems were due to the highly mechanical nature of the process, requiring precise calibration, near-perfect materials and a lot of luck.

I tested a MMU2S some years ago, publishing a detailed three part review. In my experience, the MMU2S was effectively unusable at all until I replaced the heat break in my MK2S+, which was too small a diameter to allow for filaments to be easily re-inserted.

As a result of my extreme troubles with the MMU2S I basically stopped using it, as did many others. In fact, it really caused me to stop using the MK2S+ entirely and I’ve moved on to other machines since then. After all the work required to install the MMU2S, I didn’t want to undo it all.

Now with the release of the MMU3 I am quite interested to see what’s changed to enable operators to be more successful in multimaterial 3D printing.

From the lengthy post by Prusa Research, it seems that the MMU3 uses the same operational concept as the MMU2S: a rotational mechanism to slide the filament path in front of different filaments. There is a reason for this, as they explain:

“We decided to stick with a design close to the previous generation and keep the more expensive parts (like the motors), so it’s easy and cheap to upgrade your Original Prusa MMU2 / Original Prusa MMU2S to the new version (the upgrade kit is coming in August).”

That is quite interesting, as the company traditionally offers upgrade paths when feasible. Apparently there are an astonishing 50,000 MMU2S units out there, many of which could be upgraded.

Prusa Research also said this:

“You might have noticed that we’re not specifically mentioning Original Prusa i3 MK2.5, Original Prusa i3 MK2.5S, Original Prusa i3 MK3 and Original Prusa i3 MK3S. Due to production and processing capacity, we have decided not to prepare specific packages for these printers. However, do not worry, we’ll publish an article in our Knowledge base which will describe how to adjust the Original Prusa MMU3 designed for MK3S+ to make it work with your Original Prusa i3 MK2.5 / Original Prusa i3 MK2.5S / Original Prusa i3 MK3 / Original Prusa i3 MK3S printer with some simple steps.”

So there may be hope for my effectively dead MMU2S after all.

But what’s different with the MMU3?

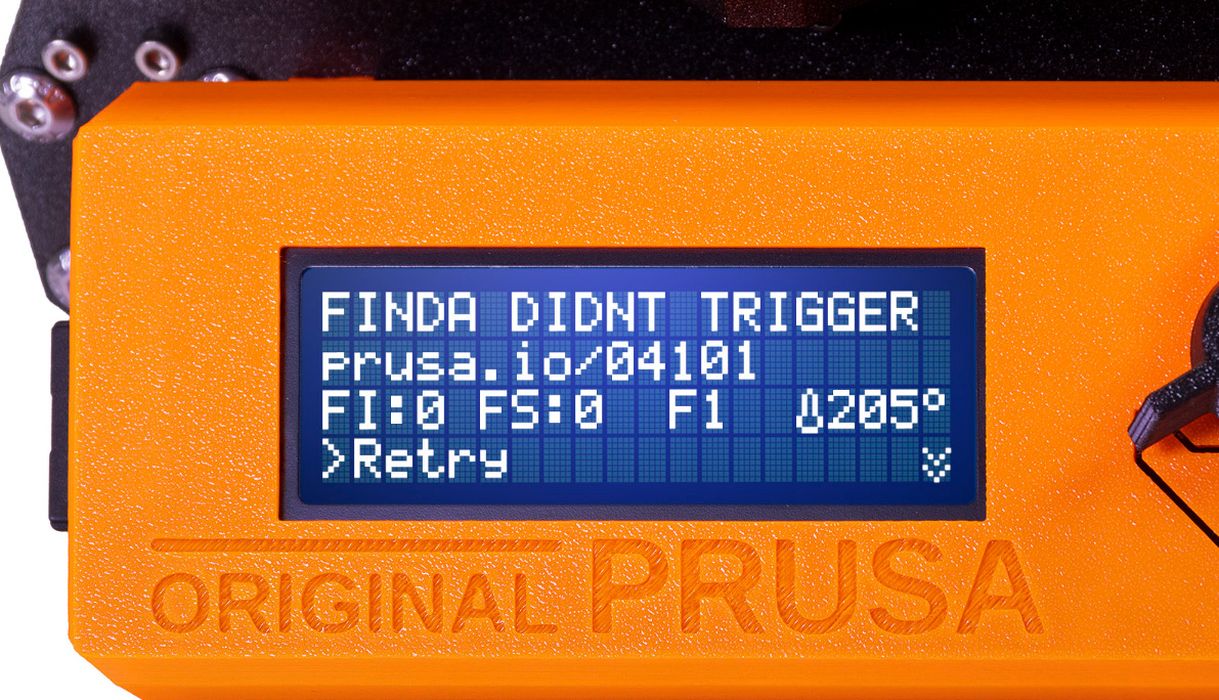

The main difference appears to be software. They’ve changed the firmware in the device so that it can properly communicate with the 3D printer. This means that intelligible messages will appear on the printer’s screen, quite different from the mysterious light patterns that would blink on the MMU2S when something inevitably went south.

This was certainly one of the biggest issues with the MMU2S: you really had no idea what was going on most of the time. Only after careful study would you begin to notice movement patterns that could be recognized. Initially the MMU2S was extremely confusing, so it seems that the MMU3 should not have those issues.

Here’s an example of this benefit:

“The printer shows real-time information from the SuperFINDA (filament sensor in Original Prusa MMU3) and the filament sensor on the screen, so you can immediately tell where there’s a potential problem.”

In addition, because the printer is more aware of the MMU3, it can then attempt to resolve error situations on its own, thus decreasing the odds of a dreaded operator intervention event.

This is also very interesting:

“Before a “user attention” error is raised, the Original Prusa MMU3 will attempt to reload the filament several times and if it fails, the unit knows where exactly it failed and may perform additional actions – e.g., use a small blade to cut the end of the filament because it is likely that a deformed filament tip is the culprit. Only when the self-repair fails, the user is notified with a proper description of the situation on the screen.”

The original MMU2S included a blade, which I personally installed, but it was never used by the MMU2S. I always felt cutting off the blobby knobs at the end of retracted filaments would be necessary — because that’s what I would constantly do when running the MMU2S. Now it seems that the MMU3 can do this automatically when required. That is a major step forward.

Physically, there are multiple differences with the MMU3. Many of these were based on community modifications that have been experimented with by expert operators, and now incorporated by Prusa Research.

One set of physical changes is all about the infamous buffer. The problem being solved is that when filaments are retracted, the retracted length has to go somewhere. If not managed, tangles and other issues could result. The MMU2S included a “buffer” device to prevent tangling, but it was so truly ineffective that I don’t think anyone actually used it.

Now the MMU3 includes an entirely new buffer design that should work much better.

Finally, the best improvement is “slightly larger PTFE” tubes, which were a constant problem on the MMU2S: retracted filament will almost always have a blob of material on the end, increasing its diameter. These would frequently get jammed in the thin tubes, so making them bigger will almost certainly eliminate many interventions.

The MMU3 is now available, priced at US$299. For those still feeling burned by the unreliable MMU2S, Prusa Research offers the possibility of using the new MMU3 firmware on existing MMU2S units. This allows operators to get a feel for the new approach and possibly persuade them to buy a new MMU3.

Via Prusa Research

I was also very disappointed by the the MMU(2), not sure i will spend again Money for it.

The last disappointing product was the prusa enclosing, metal parts are highly accurate and for sure the expensivest parts, but i had to print a lot of plastic part before i could use it, and still not all promised Features available.

Maybe i should buy next time at any other competitor to force Prusa Research to going back to better/innovative Products and complete Assembly Kits.

Dont get me wrong, the MK3(S(+)) is still good for me, but everything else is in the meantime a redflag especially on this pricetags.

Just get a bambu printer with AMS.(p1s 950 or X1C for 1450) I have had mine for a year and have done thousands of filament swaps with little issues. You can start with 4 colors and go up to 16. The slicer is based around the filament changer. There is a filament cutter in the print head and best of all the printer just works consistently, reliably, local or when away.

Prusa is years late for a functional mmu and the competition beat them on several fronts.

Obviously it was not properly beta tested.

If at all.

Inexcusable.