Quantica announced an important strategic manufacturing partnership that could drive their inkjet technology forward.

If you haven’t heard of Quantica, that’s not surprising. The Berlin-based startup was in stealth mode for several years, and emerging into the spotlight only recently.

The company has been developing a way to revolutionize resin 3D printing using a new form of inkjet technology.

Most of today’s resin 3D printing involves vats of liquid photopolymers that are selectively cured using light energy. That approach has a massive constraint: only one material can be used. Quantica’s technology can change that entirely.

Instead of using a vat, they instead deposit single drops of resin using an advanced inkjet system. This allows multiple materials to be used: second (or third) passes of a toolhead can squirt out drops of secondary (or tertiary) resins.

That’s not quite new, as other 3D printing processes have done this for years, including Stratasys’ PolyJet. However, the inkjet system has a very significant issue: in order to effectively pass through the microscopic inkjet nozzle the resin must be very thin. That’s a problem because low-viscosity resins tend to be fragile when cured, and greatly limit the additives that can be employed in resin mixes.

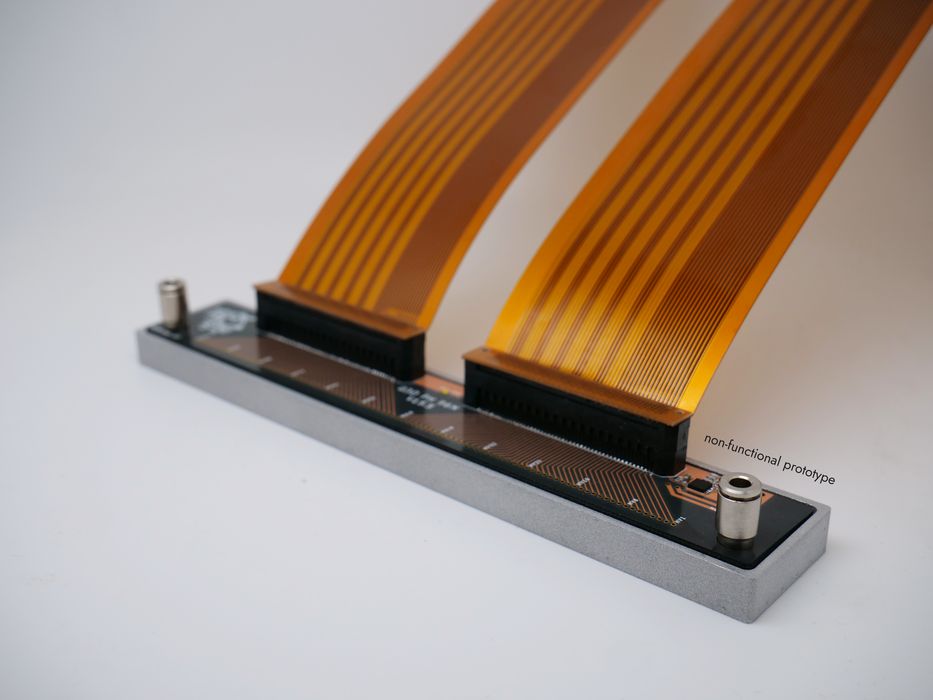

Enter Quantica’s NovoJet printheads. These are similarly microscopic, but have the ability to handle resins that can be as much as 15X as viscous as normal inkjet resins. That means a 3D printer equipped with these printheads could print a far wider variety of materials, including new engineering materials that open up new application types.

Quantica bundled NovoJet technology into their first 3D printer, the T1 Pro, announced in late 2021.

But as a startup, Quantica will face the scaling-up problem: how to transform the product into something that can be manufactured in much larger volumes when serious sales levels occur. This is a problem that every startup must overcome eventually, if they hope to grow. Some companies actually don’t make it over this barrier and eventually fade away.

Quantica took a very important step by announcing a partnership with Xaar to manufacture the NovoJet printheads.

Xaar is well-known as one of the leading manufacturers of inkjet printheads, and their products are used in countless 2D and 3D printers from many manufacturers. They know how to make inkjet printheads at very large scales.

Quantica explains the arrangement:

“Xaar and Quantica have signed an exclusive commercial partnership to manufacture Quantica’s NovoJet printheads, enabling ultra high viscosity printing for 2D and 3D printing applications. This powerful partnership combines Xaar’s expertise in inkjet printhead manufacturing with Quantica’s ultra high viscosity printhead technology.

Manufacturing will take place at Xaar’s high-tech facility in Huntingdon, with both companies expecting the initial NovoJet printheads to be shipping in Quantica’s first 3D printers from the end of 2023.”

Interestingly, the deal also allows Xaar access to Quantica’s methods of handling high viscosity resins, so we may see similar printheads eventually appear from Xaar in the future. These could in turn be incorporated into more types of advanced inkjet 3D printers.

The bottom line here is that Quantica seems to have overcome one of the key barriers to scaling up, and their future became a bit more positive.