Photocentric has been moving forward with a number of initiatives.

The UK-based company is well-known as one of the few base providers of photopolymer resin that is remade into countless resin products from their clients. They also produce many resins with their own branding.

But in the past ten years they’ve also delved directly into 3D printing, rather than just supplying materials. They produced an increasingly powerful series of resin 3D printers, which now include the mighty Liquid Crystal Titan, which they bill as the “largest, high resolution LCD 3D printer in the world”. This device has a massive build volume of 700 x 395 x 1200 mm, with a pixel size of less than 0.1mm.

This capability has led to their equipment being frequently used for end-use part production: you can squeeze a great many parts into their build volume in a single print job.

During the pandemic, the company opened up a parts production service using printer inventory, which apparently was quite successful.

How successful? We were told one of their customers (using Magna 3D printers) received an order for one million parts, which is obviously one of, if not the largest single production order for 3D printed components yet seen.

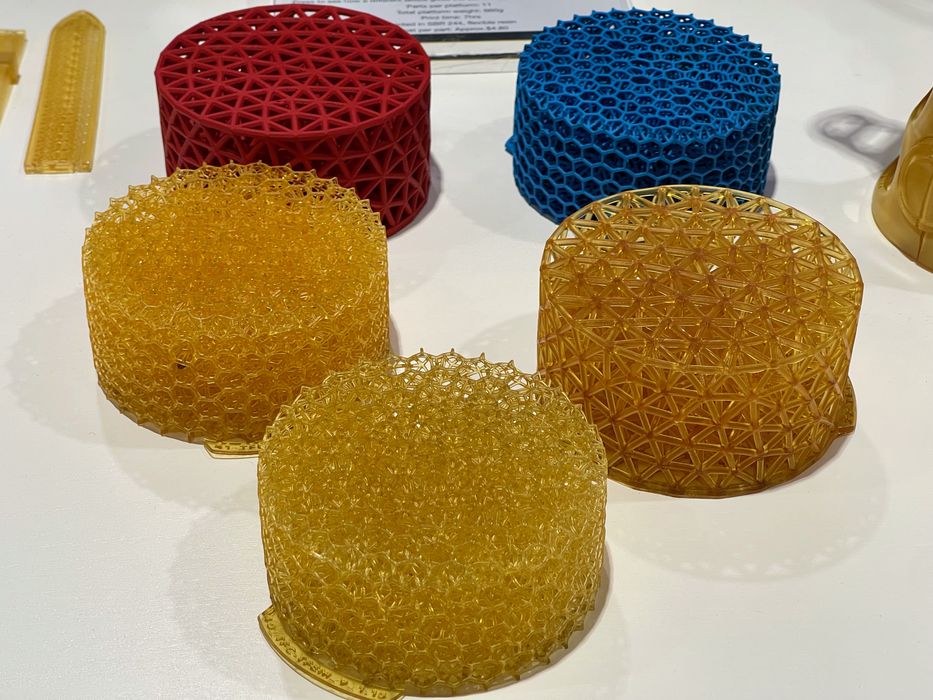

One of their most interesting recent ventures is a partnership with General Lattice. Their software allows 3D models to be generated with complex lattice structures that are easily 3D printed by Photocentric’s equipment. The lattices dramatically lower the weight of parts as well as reducing the material usage.

At top you can see several examples of how lattices can be used with their system.

We’re also told Photocentric has been working with BASF on spray coatings for 3D prints. These would be able to provide different colors for prints, as well as introducing other useful properties. This is an area that I don’t believe has been fully explored by the industry, so I am interested to see how this works out.

The company has tapped into what could be a huge and growing market niche: high resolution production parts. Their equipment is ideal for this purpose, and their supply of photopolymer resins and partnerships with chemical companies will complement their hardware capabilities.

Things are looking up for Photocentric, as they continue to expand their operations. I have a suspicion their US office, based in Phoenix, will be quite busy in coming years.

Via Photocentric