We had a chat with the folks from Co Print to find out the latest on their interesting 3D printer accessories.

Co Print is an Istanbul-based company that’s been around for a few years. Their most notable product has been the Co Print Multi-Filament 3D printing module, a device that is able to switch filaments on the fly, enabling multicolor or multimaterial 3D printing.

It’s reminiscent of the Prusa MMU in that it can swap filaments — although the Co Print can switch seven, more than the five offered by the MMU. It is also reminiscent of the Mosaic Manufacturing Palette in that it is a separate unit from the machine. The MMU must be permanently installed on the 3D printer, while the Co Print can be moved around to different machines — as long as they have Bowden-style extruders.

The Co Print is compatible with a lengthy list of 3D printers, and I suspect it works on many more that are not listed. As long as the machine is Bowden-style, it has a chance of working as far as I can tell.

The original Co Print was quite popular: its Kickstarter campaign raised over US$200K, and I’m told by company representatives that they’ve sold them in 70 countries, but most purchases were in the USA.

Since the development of the Co Print, the company has gone on to produce several other very interesting 3D printer accessories.

One of them is the Phoenix hot end. This would appear to be a standard hot end, but there are some interesting differences. The components are specifically designed to ensure heat does not creep up the filament path. Because of this, the Phoenix hot end is ideal for multi-material 3D printing where hot filaments are repeatedly pulled back through the hot end.

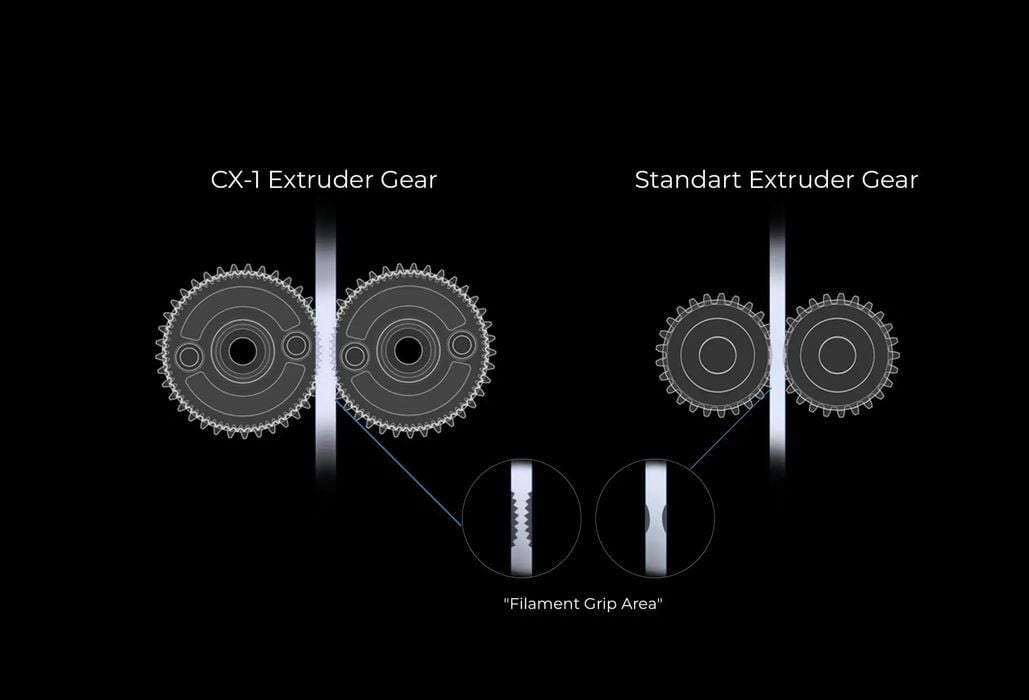

Another product is the CX-1 extruder. This unit is designed to provide particularly tight grip on the filament, again a bonus for multi-material printing where there is great deal of stop-and-go movement.

You can see in this diagram how tightly the filament is grabbed by the CX-1. I don’t believe I’ve seen this depth achieved on other extruders.

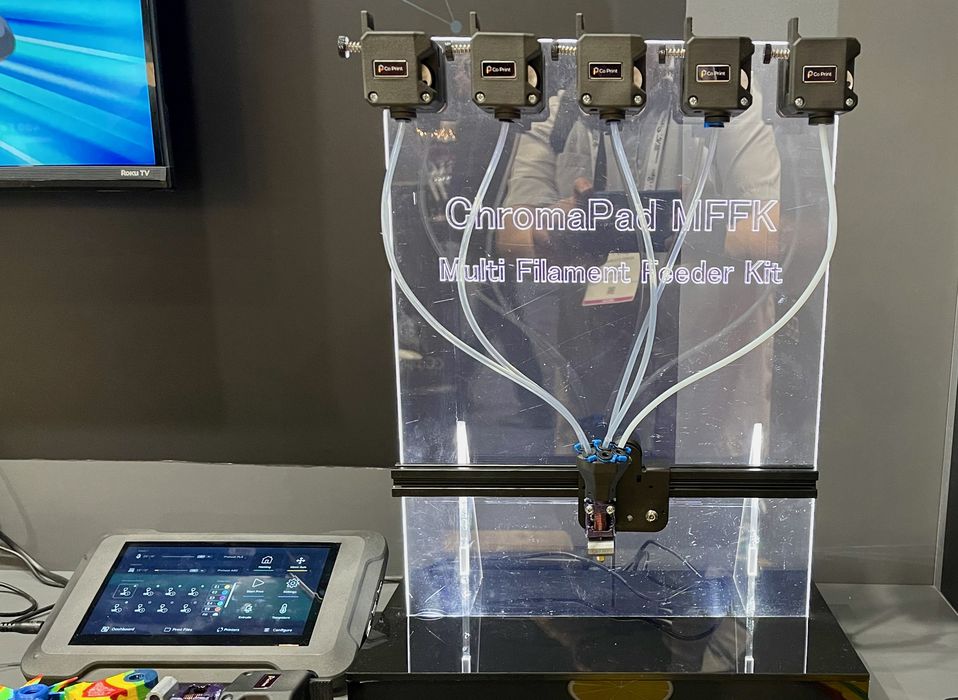

Finally, they have the Chromapad. This set-top 3D printer control device is unlike anything I’ve seen elsewhere. It includes several advanced functions bundled into a single unit. Let’s look at what it contains:

- Three USB ports to connect up to three 3D printers

- Eight “extruder” ports to control separate extruders, for example, on the Co Print for multi-material 3D printing

- 7” color touchscreen with well-designed UI

- One input shaper port for vibration calibration

That last item is important because it enables the use of advanced Klipper firmware that uses input shaping to dramatically speed up printing. The software in the Chromapad “has been specifically redesigned based on Klipper”. This means that printers controlled by the Chromapad can run 3-5X faster and still produce high quality output.

But there’s a big difference here: this is basically Klipper for multi-material 3D printing! I don’t believe there is anything else like it in the industry.

Normally MMU 3D print jobs are incredibly slow due to the frequent filament swaps. It’s not uncommon to see multi-material prints take 5-10X longer than a “straight print”, so anything to speed up the process is welcome.

But wait, there’s more: this all means that the Co Print is able to multi-material 3D printing at high speed! This could be the only high speed multi-material 3D printer configuration available, and certainly the only one with a seven filament option.

Co Print produces several unique products that I believe could be quite useful to many looking to modify their desktop FFF 3D printers for advanced functions.

Via Co Print