Researchers at the University of Waterloo have developed a new way to use 3D printing for wound dressings.

The new approach leverages two factors: 3D printing’s ability to create shapes that match perfectly to the patient’s body geometry, and a new material that provides a variety of useful functions.

The intention is to use these new wound dressings for the most serious wounds, such as burns from fires or cancer victims. These are problematic due to their size, but that’s not as much of an issue when you can create custom-sized dressings with a 3D printer.

The 3D printing is done by first performing a 3D scan of the patient, in particular the areas requiring the dressing. Then the print is then produced on an MSLA device, and applied to the patient.

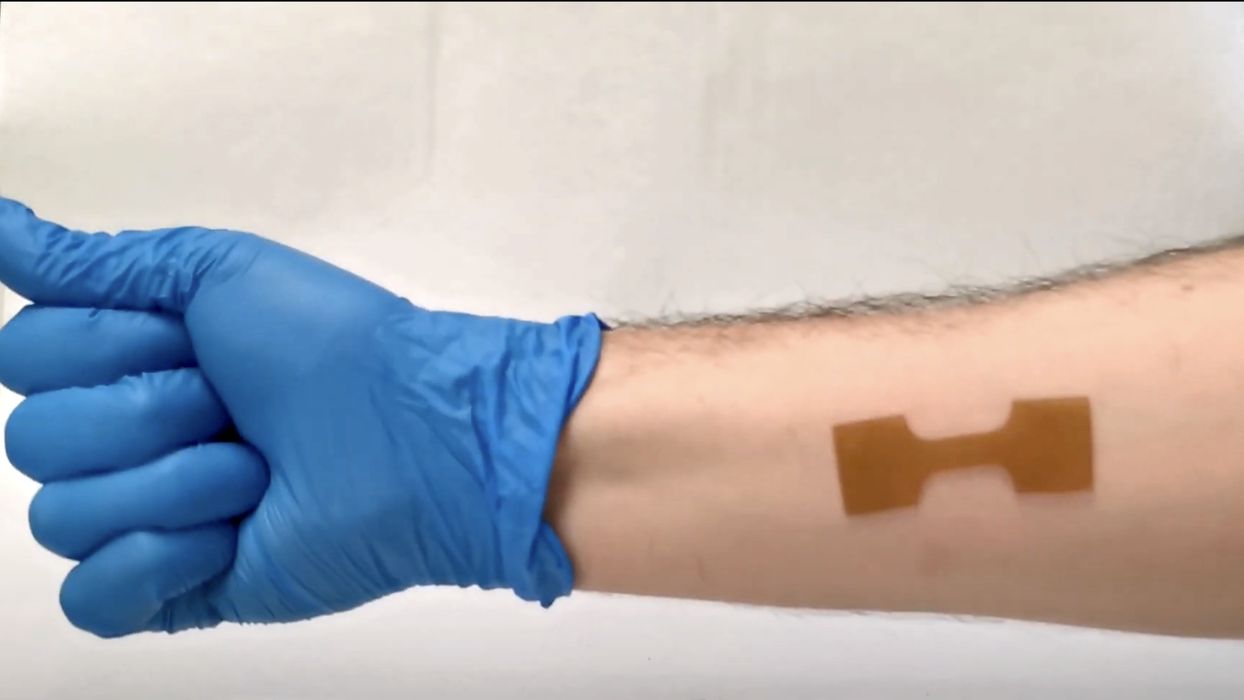

The material for the dressing is quite interesting. First, it has “smart adhesion”. In other words, it sticks perfectly to the body. In this video they demonstrate how the material sticks at body temperature, but not otherwise:

The dressing is also easy to peel off when it needs to be changed.

The material is also capable of delivering drugs at a metered rate through to the body. They explain the benefit:

“The material also has applications for cancer treatment. In traditional chemotherapy treatment, a patient may need to be in a clinic for hours, which can be tiring and uncomfortable. This dressing can provide a constant drug release outside the clinic setting, alleviating some of the challenges associated with traditional methods.”

This material is apparently created with a combination of a polymer derived from seaweed, a thermally responsive polymer, cellulose nanocrystal and the usual photopolymers for 3D printing.

If that wasn’t enough, it appears there are further potential applications for this technology. University of Waterloo Professor Dr. Boxin Zhao explains:

“We also envision applications in the beauty and cosmetic industry. Cosmetologists can utilize 3D scanning technology to analyze their clients’ facial features and customize hydrogel masks infused with specific facial and skin regimen products. Additionally, this innovative approach can benefit plastic surgeons.”

This is a notable development for healthcare, but also for 3D printing in general: new materials can often be found useful in many other areas beyond their original targets.

This also shows how critical the development of new materials can be for specific applications.

Fortunately, we won’t run out of designs for new materials anytime soon.

Via University of Waterloo and Science Direct