Charles R. Goulding and Preeti Sulibhavi look at the work being done by several major plastics producers to increase sustainability through 3D printing.

In a February 20th, 2023 article in Barron’s, titled “Rethinking Plastic,” the topic of whether or not recycling has reduced the amount of “new plastic” in circulation was discussed. The article covered the success and failures of plastic recycling.

To develop the story Barron’s features 6 leading plastics companies including industry giants and some specialty companies, one of which is rumored to be an acquisition target. The dichotomy with plastic is that it is a practical material that has resulted in many useful products but has damaged the environment. The industry recognizes the downsize and is striving to improve. Low prices exacerbate the problem with more new products and an unfavorable recycling environment.

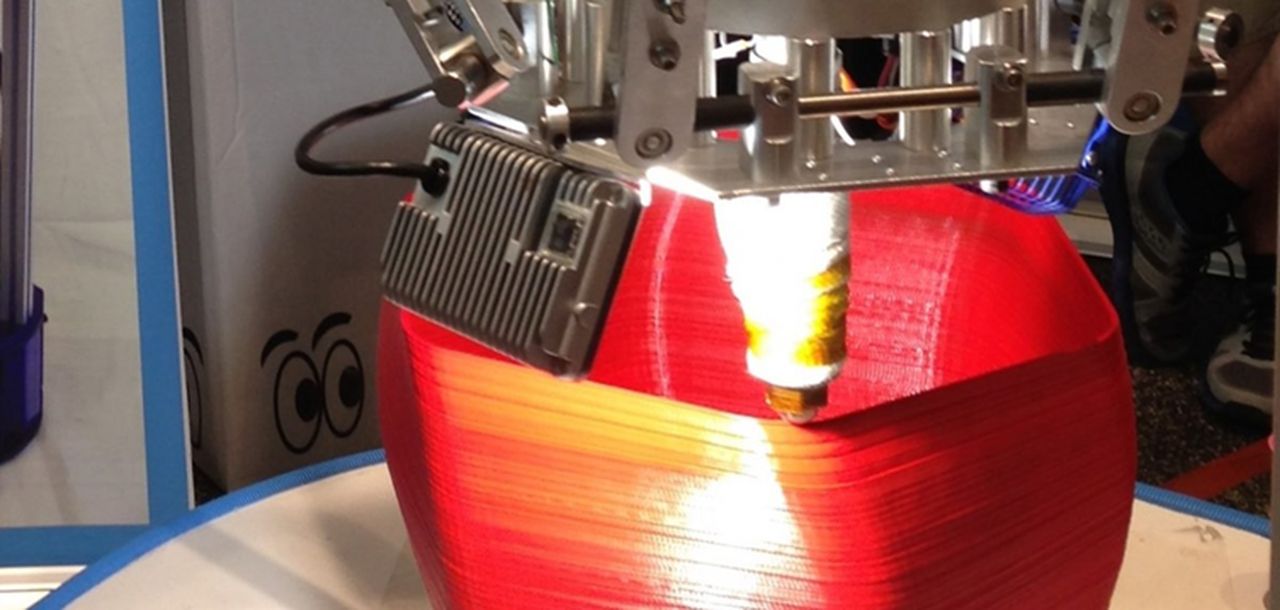

We have covered how 3D printing is impacting the efforts to reduce plastic packaging and help create a more circular economy on Fabbaloo before. Whether it was Hasbro looking to eliminate plastic packaging or chemical recycling of plastics, we have highlighted how 3D printing can assist these efforts.

But this piece in Barron’s was an eye-opener, as it indicated that recycling has barely advanced at all. Even with millions of Americans dutifully rinsing containers and filling blue bins, just 5% of plastic is recycled, according to estimates from the US Department of Energy. The bulk of it, 95%, is landfilled, incinerated, or washed to sea, all of which have negative environmental impacts.

We wanted to highlight petrochemical companies and their activities related to reducing plastics.

LyondellBasell Industries

Lyondell has always been concerned about reducing carbon emissions and developing sustainable manufacturing practices. In fact, Lyondell has launched Beon3D, it’s family of compounds that are used to create high-quality, complex 3D printed objects in one step. To create airbags consisting of mixed automotive plastic waste feedstock processed in an advanced recycling process, Lyondell used 3D printers thereby creating a circular system where plastic waste is used to create new plastic.

Dow

Dow has developed an IMAGIN3D Olefin Block Copolymer (OBC) filament is a high-performance build material that enables the production of lightweight and durable 3D printed parts, with excellent remold-ability and flexibility for an extended lifespan. IMAGIN3D™ OBC also strongly prioritizes sustainability throughout its lifecycle – Dow intends to develop a first-of-its-kind recycling program for end-users as well.

As the first polyethylene-based build material for 3D printing, this groundbreaking filament brings polyolefin properties to 3D printing, without the problematic concerns commonly associated with printing polypropylene. IMAGIN3D OBC is soluble in water, allowing it to be washed away more easily and safely, without hazardous caustic baths. Its semicrystalline structure enables excellent z-axis properties after printing and its outstanding chemical resistance enable new 3D printing applications.

Celanese

This company operates in three segments: acetyls, engineered materials, and acetate tow. The first category is used for intermediate chemicals that eventually wind up in other end products. The second category is for products ranging from auto to medical devices. The last category is for less common items such as cigarette filters. The last category mentioned includes biodegradable plastics. But as you may have surmised, the first and second categories are predominant.

Berry Global Group

Berry is responsible for taking the chemical products produced by Lyondell and Dow, etc., and turning them into consumer products like bags, bottles, and other consumables. Berry is interested in creating engineered plastics from engineered plastics and environmentally friendly substances.

Origin Materials

Origin is focused on fabricating plastics out of nonfood biomass, including wood and wood by-products. Origin has stated that it will be carbon-negative because the carbon captured in the wood exceeds the amount that is released during manufacturing processes. Its new plant in Canada will produce chemicals such as polyethylene terephthalate, a recyclable material used to make products including soda bottles and hair care products. The technology is catching the interest of industry experts and investors alike.

Univar Solutions

Currently wooed by several private-equity firms, Univar distributes chemicals to more than 100,000 customers across 115 countries. Univar operates 600 facilities globally and interestingly enough, produces tripropylene glycol monomethyl ether (TPM), which is being tested as alternative parts to be 3D printed with non-biocompatible Formlabs resins.

BASF

We have covered how BASF is involved with 3D printing in various pieces including its $10 Billion China Plant. But more recently, MIT CSAIL and BASF scientists have developed a new data-driven system to accelerate the discovery of new 3D printing materials.

According to CSAIL and BASF scientists, the new machine-learning system costs less, generates less waste, and can be more innovative than manual discovery methods. “Materials development is still very much a manual process,” says CSAIL mechanism engineer and co-lead author Mike Foshey. Foshey goes on to explain how traditionally, a chemist mixes ingredients and creates samples by hand, then tests those samples to come to a final conclusion. With this method, the chemist can only do a couple of iterations over a span of days, compared to the hundreds of iterations their system can do in the same time span.

The new experimental process enables a material developer to select a few ingredients, input details on their chemical compositions into the algorithm, and define the mechanical properties the new material should have. These results are then reported to the algorithm, which automatically learns from the experiment and uses the new information to decide on another formulation to test. We have covered how the 3D printing industry and AI/machine learning are aligned on Fabbaloo as well.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

We began this piece by rethinking the plastic conundrum at multiple companies. What we see now is that with the plethora of 3D printing activities underway additional solutions to the problem are on the horizon.

What we liked about the Barron’s article is that it took a balanced and comprehensive approach to a major problem. The industry is striving to substitute alternative materials, expand recycling and make lighter products. 3D printing is an essential element of the solution. Although the rate of progress will not satisfy critics, major problems are managed with this balanced approach.