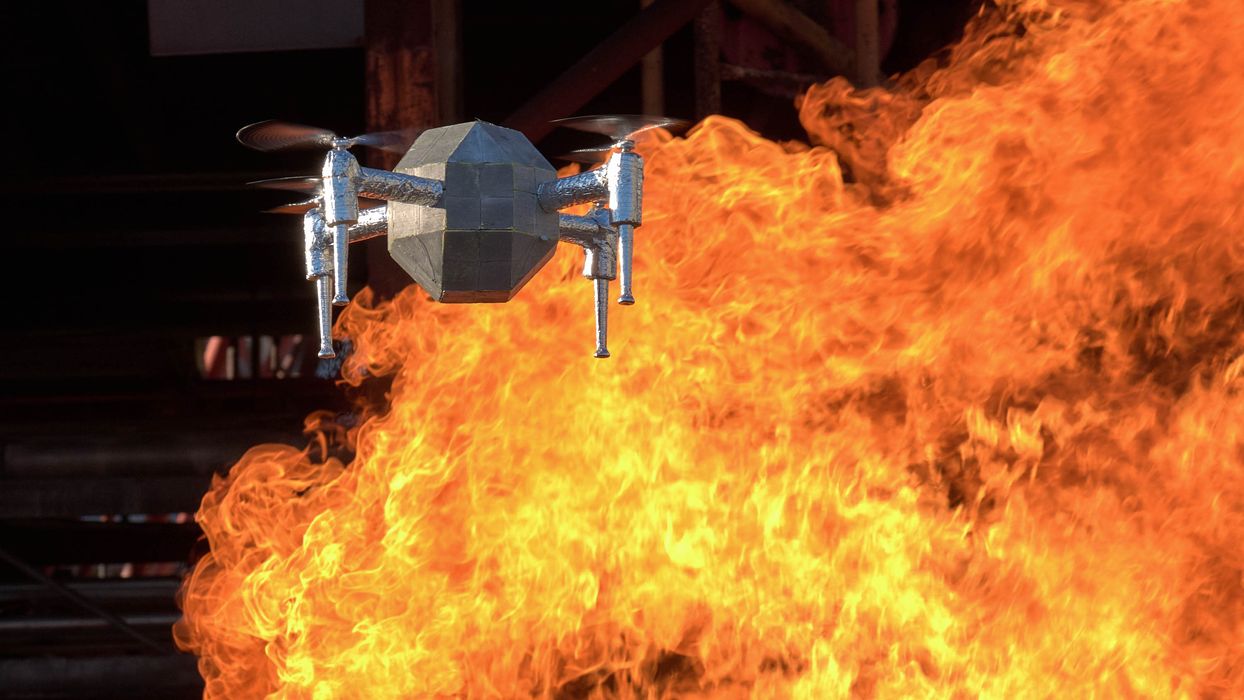

A 3D printed drone is able to venture into dangerous fire situations.

The Laboratory of Sustainability Robotics at the Swiss Empa institute has developed a specialized drone designed for firefighting operations. Key to the drone’s success are lightweight, stable, and temperature-resistant parts manufactured using Selective Laser Sintering (SLS) 3D printing.

Empa’s Focus on Sustainable Solutions

As an interdisciplinary research institute, Empa is committed to developing sustainable and resilient solutions. The institute aims to shift from a throw-away society to a circular economy, promoting a greener future for the planet. The Laboratory of Sustainability Robotics, a department within Empa, focuses on creating flying robot platforms, among other projects.

Firefighting Operations with Drone Technology

“Every day, firefighters risk their lives going into unknown environments,” says research engineer David Häusermann. His team spent approximately six months developing, constructing, and testing a fire drone.

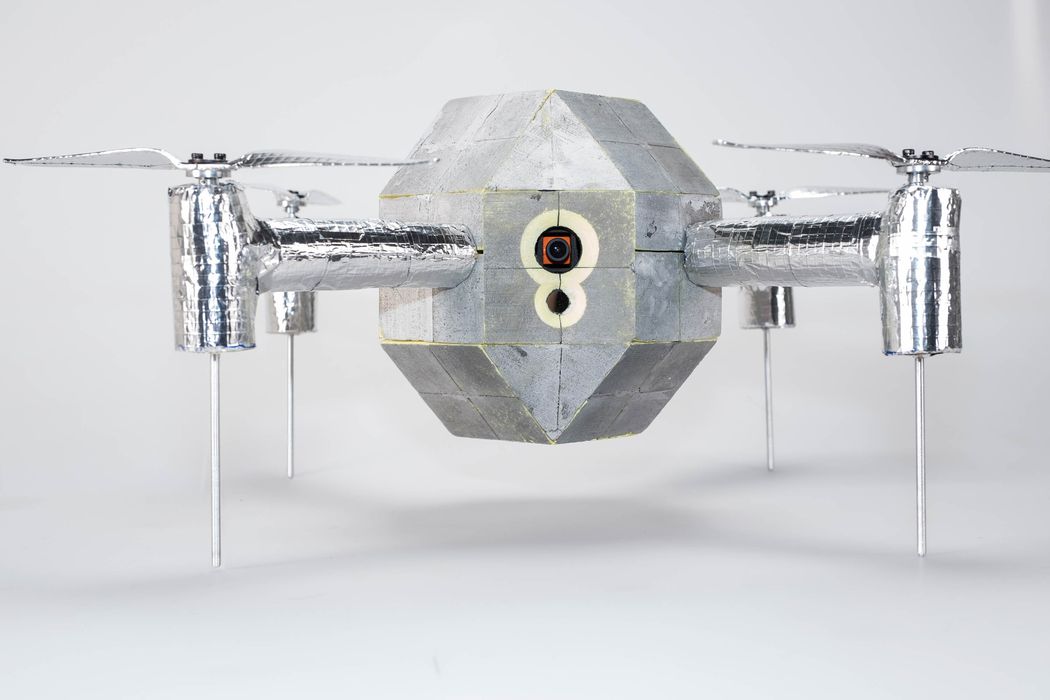

The drone serves as reconnaissance equipment, providing a view of danger zones from a safe distance using both an infrared sensor and a conventional RGB camera. This capability allows for risk minimization and increased efficiency during firefighting operations.

Withstanding Extreme Temperatures and SLS 3D Printing

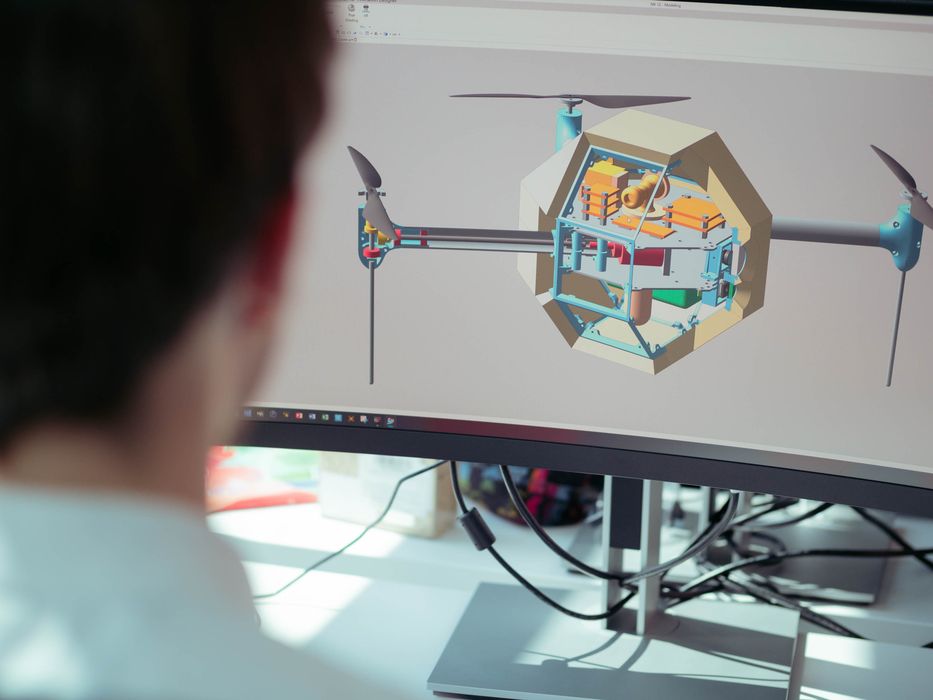

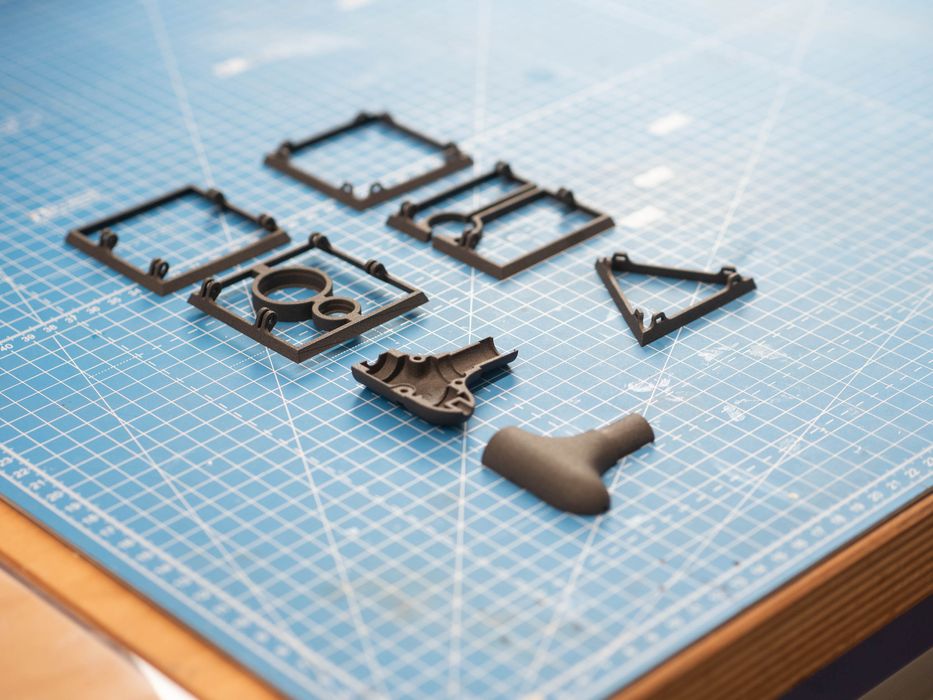

During the development phase, the team used Fused Deposition Modeling (FDM) additive manufacturing technology for its design freedom. However, as the project progressed, they switched to laser-sintered PA12 elements for better accuracy, material quality, and temperature resistance. Unlike FDM, SLS eliminates the need for support structures during printing.

Successful SLS Parts Integration

Sintratec provided 3D printed parts for mounting frames of the aerogel shell, fixing points for electronic components, clamps for the rotor arms, and gearbox housings.

Häusermann explains:

“The parts Sintratec provided to us fulfilled all of our project requirements and performed as expected when tested in real-life conditions.”

Häusermann is convinced that “the SLS technology and its excellent material properties are perfect for drone construction – high quality, robust, and heat-resistant parts.”

Potential Industry Applications

This development has the potential to revolutionize firefighting operations, enhancing safety and efficiency for both firefighters and affected structures. The innovative use of SLS 3D printing for drone construction also opens new possibilities for other industries requiring high-performance, temperature-resistant components.

For instance, drones with these capabilities could be utilized in search and rescue missions, where operating in extreme environments is often necessary. Additionally, the oil and gas industry could benefit from drones capable of performing inspections and monitoring in high-temperature environments, such as refineries and drilling sites.

Other potential applications include the energy sector, where they could assist in maintaining solar panels, wind turbines, and power plants. The ability to create lightweight, robust, and heat-resistant components through SLS 3D printing may significantly expand the range of applications for drones in various industries.

Relevant links:

Via Empa, Laboratory of Sustainability Robotics and Sintratec