Charles R. Goulding and Preeti Sulibhavi suggest there is industrial success among countless layoffs in the US tech industry.

In the first full February business week 20,000 mostly tech workers lost their jobs, but the US industrial sector posted strong results. Three industrial powerhouses with outstanding stock performance include BorgWarner, Parker Hannifin, and Ingersoll Rand.

BorgWarner transmission [Source: BorgWarner]

BorgWarner

Employing approximately 49,300 people worldwide, BorgWarner had net sales of US$2.9B for 2022. The wide array of power electronics and boosting technologies, including turbines, means that BorgWarner has plenty of opportunities to use 3D printing. We have covered BorgWarner and 3D printing previously on Fabbaloo. We covered how BorgWarner acquired Delphi and can leverage Delphi’s carbon 3D printing for prototyping and much more.

When Andrew Lawlor, engineering supervisor at BorgWarner, spoke about 3D printing at New York State’s FuzeHub Manufacturing Extension Partnership, we included an article in Fabbaloo. BorgWarner’s product lines range from battery systems, chargers, controllers, electric vehicle or EV transmissions and motors, power electronics, and thermal management systems, all of which have some 3D printing integration potential.

Stratoflex Products’, a Parker Division, 3D printed components [Source: Parker]

Parker Hannifin

During 2022, Parker had sales of US$15.9B and employed about 55,090 people. Founded in 1917, Parker specializes in a variety of industrial sectors including aerospace, healthcare and life science, HVAC, oil and gas, and transportation to name a few. We have covered Parker Hannifin in a previous Fabbaloo article where we highlighted its additive manufacturing facility as well as Stratoflex Products, a division of Parker that has been using 3D printing for its fluid transfer products.

Ingersoll’s industrial extrusion 3D printer [Source: Aniwaa]

Ingersoll

With sales of about US$5.63B for fiscal year 2022 and a team of 16,000 employees, globally, Ingersoll Rand provides high quality industrial products. Ingersoll Rand specializes in air compressors, dryers and filters.

In conjunction with Oak Ridge National Lab (ORNL), Ingersoll has created a large-scale 3D printer called Wide and High Additive Manufacturing (WHAM). This 3D printer can print objects measuring up to 23 ft. x 10 ft. x 46ft ( 7010 x 3048 x 14021 mm). Ingersoll has already incorporated 3D printing into many of their compressors, most notably their shrouded impellers which are fully 3D printed, and the company has continually evaluated how additive manufacturing can be incorporated into their air compressor assemblies.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

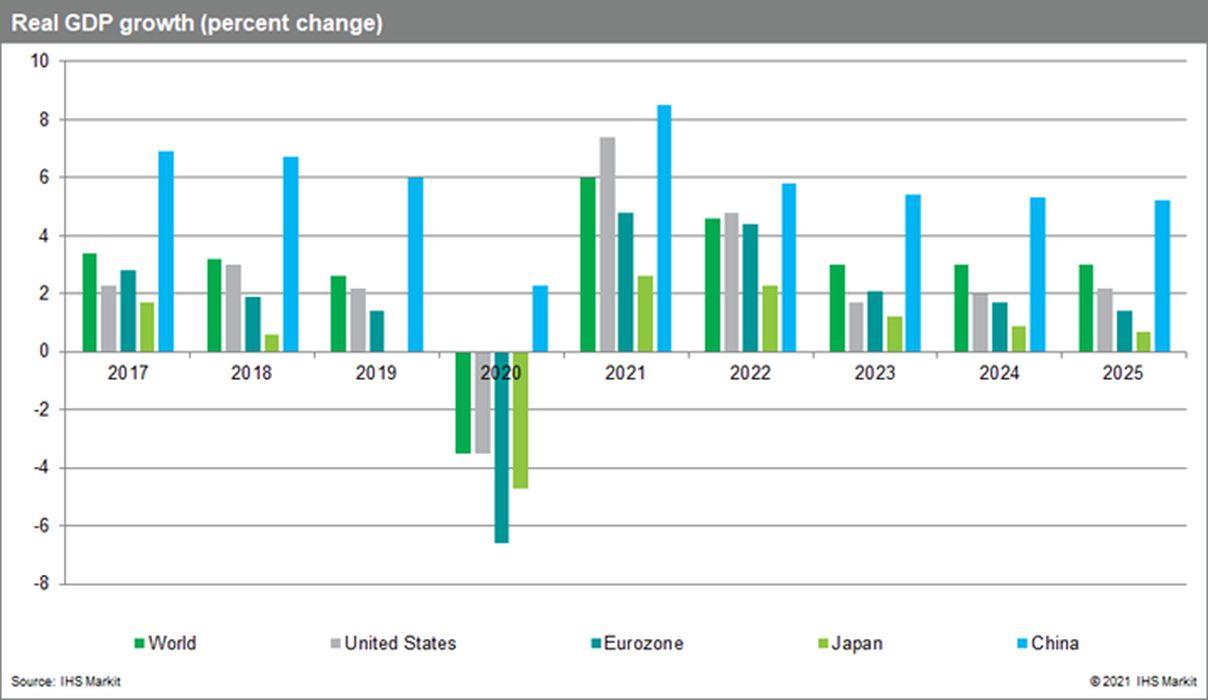

There are many reasons to be optimistic about the economy, one of which is the strong industrial growth of the US economy despite tech layoffs recently. The companies thriving in this market include companies that have strong 3D printing backgrounds.