Charles R. Goulding and Preeti Sulibhavi foresee much 3D printing for Boeing 747s in the future.

On January 31, 2023, Boeing delivered the last 747 it will assemble to Atlas Air. Nicknamed, “Queen of the Skies,” the 747 is arguably the most recognizable airplane model in the world and it incontrovertibly revolutionized the way we travel more than half a century ago.

While the airplane model is “bowing out” now, it does not signal the end of Boeing servicing the 747s. Boeing has stated it will continue servicing 747 parts until 2069 when the last 747 jet is expected to lose utility. So the planes will still be gracing the skies, only no newer ones will be added to the current inventory.

This means that Boeing will need a high-tech solution to meet the demand for replacement parts. 3D printing can be utilized here, and, in fact, currently more than 70,000 3D printed parts appear in Boeing products. And Boeing attributes some of its environmentally responsible manufacturing processes to 3D printers. These 3D printed parts are not necessarily the flight-critical parts, but mostly comprise custom designed interior components, which can be 3D printed on demand in the future without the need for a large physical inventory of spare parts.

In fact, the Boeing 787 Dreamliner is the first commercial plane with a metal 3D printer installed. Boeing is no stranger to the 3D printing industry and has benefitted from the technology. The Boeing Additive Manufacturing Center (BAM) opened in Auburn, Washington in 2022 and helped Boeing through the Covid-related supply chain crisis at the time.

Many airlines are looking to find new models that are more fuel efficient and cheaper to operate than the 747, which is what spurred Boeing to bid its 747 good-bye.

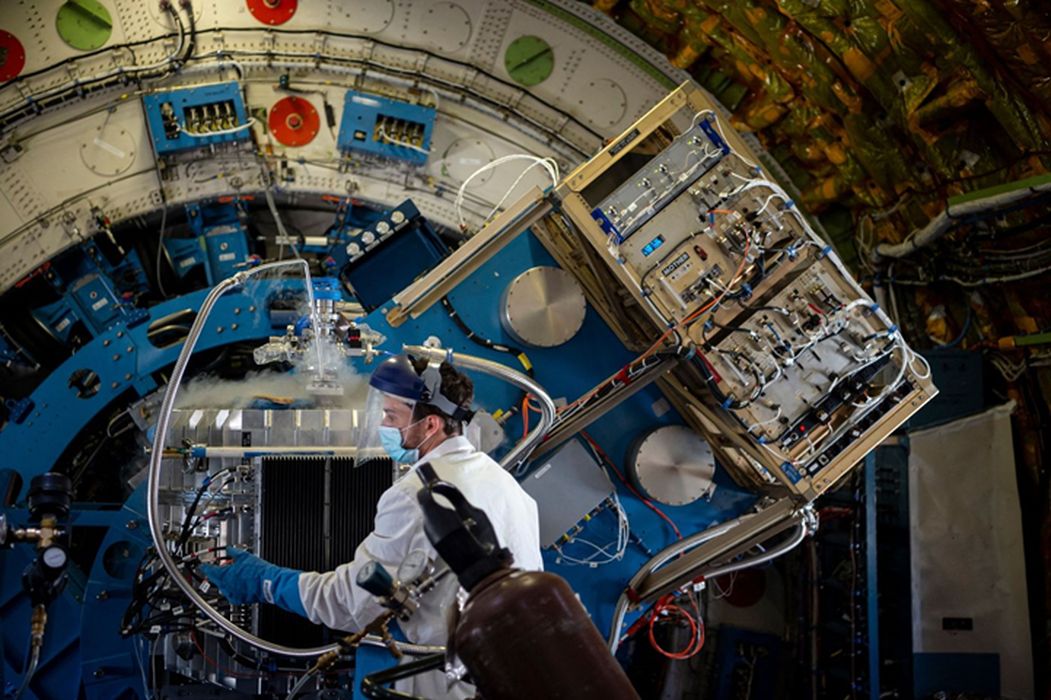

It should also be noted that Boeing 747 parts, such as the cabin, have been used for space exploration as well. The Shuttle Carrier Aircraft (SCA) are essentially two modified Boeing 747 aircraft that NASA uses to transport Space Shuttle orbiters.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

All Hail the “Queen”

Many people took their first flight in a Boeing 747, particularly if it was an international flight. There are sentimental reasons for noting this landmark event, but there are also technical reasons for marking this as an opportunity as well. The use of 3D printers can assist Boeing in servicing replacement parts for the current fleet of 747s.