Meltio announced a new software ecosystem for their manufacturing solutions.

Spain-based Meltio uses a unique additive manufacturing technology to deposit metal to form 3D objects. Their system involves a wire feed that is instantly melted with powerful lasers. By moving the print head around in 3D space, it’s easily possible to create fully solid metal parts. They even have a way to use two different metals in the same print job.

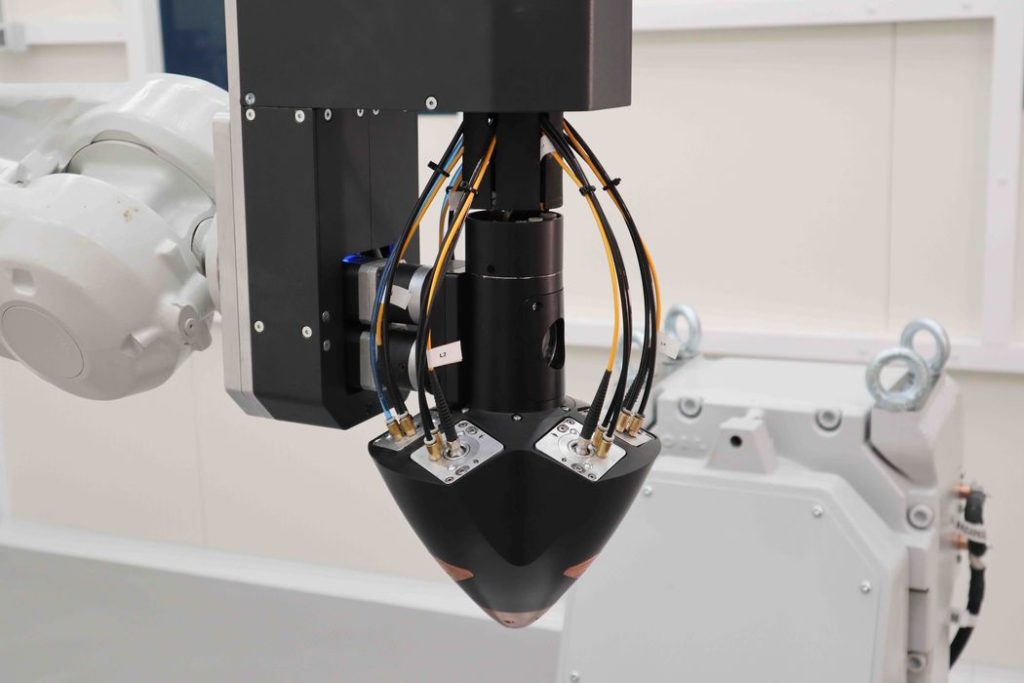

Their technology is implemented in two ways. First, they offer the M450, a standalone metal 3D printer that uses their proprietary technology. However, they also offer what’s called the “Meltio Engine”.

The Meltio Engine is basically a specialized toolhead that can be placed on other equipment. Meltio offers two configurations: CNC or Robotic arm integration.

The idea is that operators of such CNC or robotic equipment can easily “go additive” by adding a Meltio Engine toolhead to their existing manufacturing equipment. This could be vastly less expensive than buying a dedicated metal 3D printer of the same print volume, if indeed such equipment even exists — some CNC equipment is room-sized.

The implication here, however, is that each of these existing CNC and Robotic systems are already in operation at the customer site and use existing software to drive them. That software is not likely to change just when adding a toolhead, because the customer already has procedures, training and software licenses in place.

To that end, Meltio has been working behind the scenes with a number of software providers to ensure their toolhead works with each of the software options.

This week Meltio announced a more formal arrangement: the Meltio Engine Software Partners Ecosystem. This is a group of software companies that have officially certified the use of the Meltio Engine on their respective software products.

The partners number twelve, and include:

- SKM DCAM by SKM Informatik

- AdaOne by Adaxis

- AiSync by AiBuild

- Esprit by Hexagon

- Fusion 360 by Autodesk

- Aplus+Mastercam by Camufacturing and Mastercam

- Hypermill by OpenMind

- SiemensNX by Siemens

- Hy5CAM by 1ATechnologies

- RobotStudio 3D Printing PowerPack by ABB

- SprutCAM X by SprutCam

Meltio CEO Angel Llavero said:

“For a year we have been working with all of them sharing the needs that we understood most suitable for our customers, going as far as sharing as well as in some cases sharing the mathematical algorithms needed for the functionalities we required. The result of this collaboration between our engineers and the teams of these companies has now resulted in offering this software platform to the market.”

The idea here is to increase the confidence by prospective customers for the Meltio Engine. When prospects ask the inevitable question, “Does your system work with our [insert software tool]?”, it’s a great deal better to say “Yes, it’s certified!” Instead of “hold on, we’ll check with them.”

This should open the doors for more streamlined talks with prospects and generally increase sales possibilities for Meltio.

Via Meltio