I saw the biggest removable print plate ever.

Removable print plates are pretty much the de facto standard for desktop FFF 3D printers these days. In the past rigid plates usually adhered to the print, but caused all kinds of difficult — and dangerous — activity to remove prints.

I can personally attest to slicing up my appendages on several occasions when wrestling a print stuck on a glass plate with a sharp chisel. Not fun at all.

The world of 3D printing changed forever when someone — and I really don’t know who — invented the removable spring steel plate concept. A magnetic back holds the plate securely down during printing, and a (most often) PEI coating holds the print on the reverse.

When the print completes, removal of an object is often as easy as twisting the steel plate and the rigid object just pops off. This works almost every time — unless you for some reason want to print an object with flexible material. Then there’s issues because the model bends along with the plate and doesn’t pop off.

[Aside: for this reason, never try out a flexible filament with a test print in the center of your build plate. Always do a small test on the side to see how well it adheres. You may find it nearly impossible to remove, so at least you didn’t ruin the middle of your build plate.]

Nevertheless, the removable plate concept has taken over the world of desktop 3D printing and today there are very few devices that still use rigid print plates.

But how big can you make one of these removable print plates?

It turns out the answer is “pretty big”.

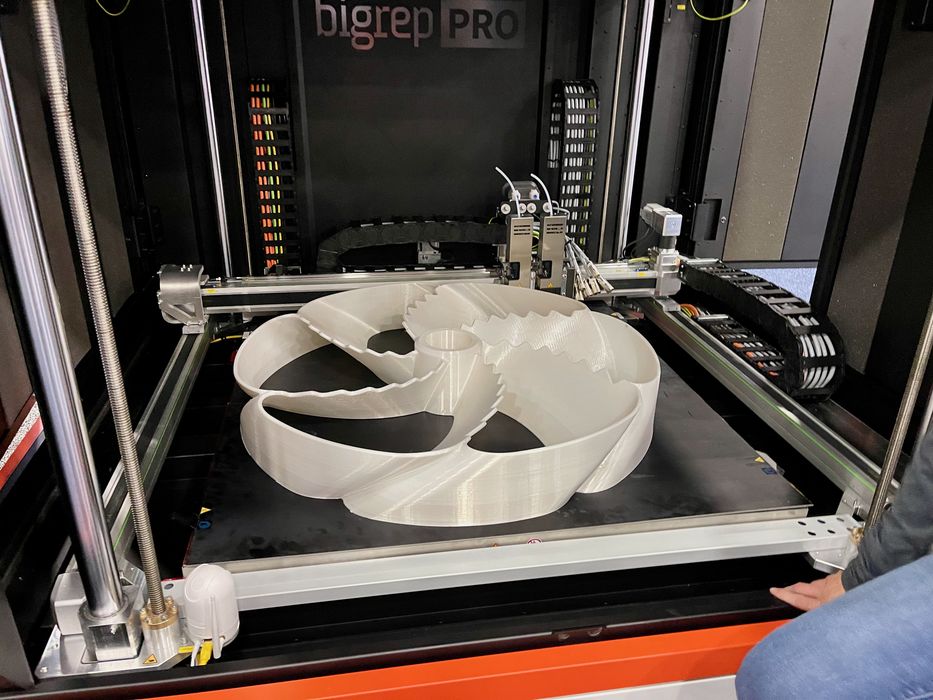

In looking at a BigRep PRO 3D printer recently, I realized this machine has a removable build plate!

The BigRep PRO is one of the largest FFF 3D printers you can buy, with a massive build volume of 1000 x 1000 x 1000. That’s one meter on a side, quite large. Intended for industry to produce massive prototypes of propellors, bathtubs and similar large objects, the BigRep PRO includes all the learnings from years of experience developing large-format 3D printers.

Large format 3D printers have a problem that the smaller devices don’t have: the gigantic prints are quite heavy and aren’t necessarily easy to lift. It’s a non-trivial operation to get prints out of a large device.

BigRep has had plenty of experience with this problem, and their solution these days is to use a print plate quite similar to those found on smaller devices. The print plate allows BigRep operators to slide the entire print out quickly and insert a fresh plate so that the next job can begin immediately. Then the removed plate can be twisted (likely by a couple of people) to remove the first print.

Here’s a short video of the plate in action:

The flexible print plate is one of the best ideas ever invented for 3D printing, and it now benefits both small and large 3D printers.

Via BigRep

Do you know what type of product is? Polyimida ? Very good!!