SPONSORED CONTENT

BuildBee is a new online tool for 3D print job preparation.

You may not yet have heard about BuildBee, simply because it’s a relatively new tool. The Australian company was founded only in 2018, as a result of the founders solving a problem, a familiar story in the 3D print world.

BuildBee Background

The founders, Leanne Connelly, Matt Connelly and Fletcher Thompson, had been operating Me3D, a company that manufactured and sold 3D printers. In their work with customers they quickly found that the job preparation experience was less than ideal. Slicing software is typically confusing, particular to new 3D printer operators, and frequently doesn’t have the functions desired by many.

In response, they developed BuildBee, a cloud-based 3D print slicing tool that can prepare and run jobs on network connected 3D printers.

It seems they created a very desirable tool, because BuildBee now has 70,000 customers using it worldwide. Today their team numbers nine providing support, new feature development and marketing.

But how does BuildBee work and what does it do for you?

BuildBee Configuration

While the core of BuildBee resides in the cloud, it must have a way to connect to your 3D printers. To simplify this connectivity, BuildBee has devised several methods for doing so, and operators simply choose the easiest for their 3D printer configuration.

The first method is by using BuildBee Desktop. This is a desktop app that’s currently available for both Windows and Mac OS operating systems. This software uses a standard USB connection to the 3D printer.

BuildBee Desktop then works with the cloud to store files and prepare jobs, which then pass through the desktop app on their way to the 3D printer.

For some operators that’s not an ideal configuration if you need to use your desktop computer for other purposes, so BuildBee provides another approach: a set top box that attaches to the 3D printer’s USB port and communicates directly with the cloud over WiFi.

There are two ways to do this. First, BuildBee provides an Octoprint plug-in that provides the necessary functionality. This is the simplest approach for those with an existing Octoprint setup.

The second method is to use Buildbee’s own BuildBee CloudDock. This is software that can be easily installed on a Raspberry Pi connected to the 3D printer. BuildBee provides extensive instructions on how to set this up for those unfamiliar with Raspberry Pi configurations.

Once one of these approaches is installed, a 3D printer can be operated directly from the BuildBee cloud, and even via their Android / iOS mobile apps. Because the system is cloud-based, a BuildBee user is able to operate connected 3D printers from anywhere, anytime, so long as they are connected to the Internet. This is different from many Octoprint installations that are confined to the local area network.

BuildBee Features

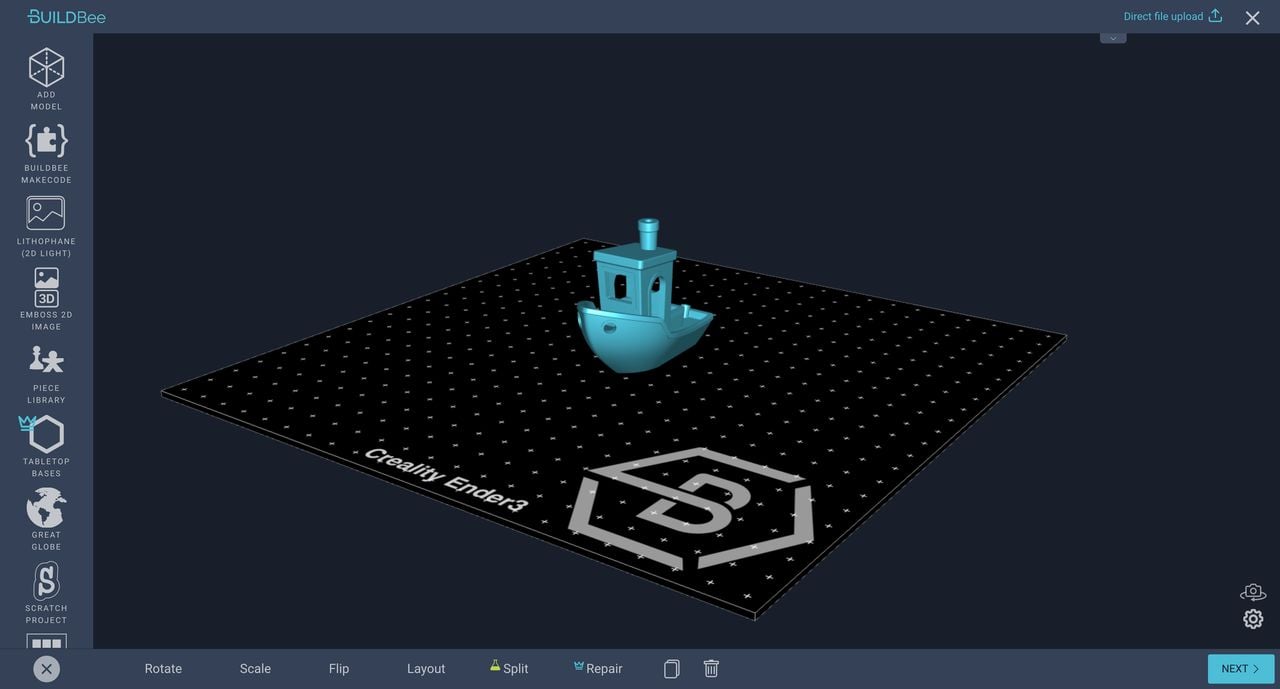

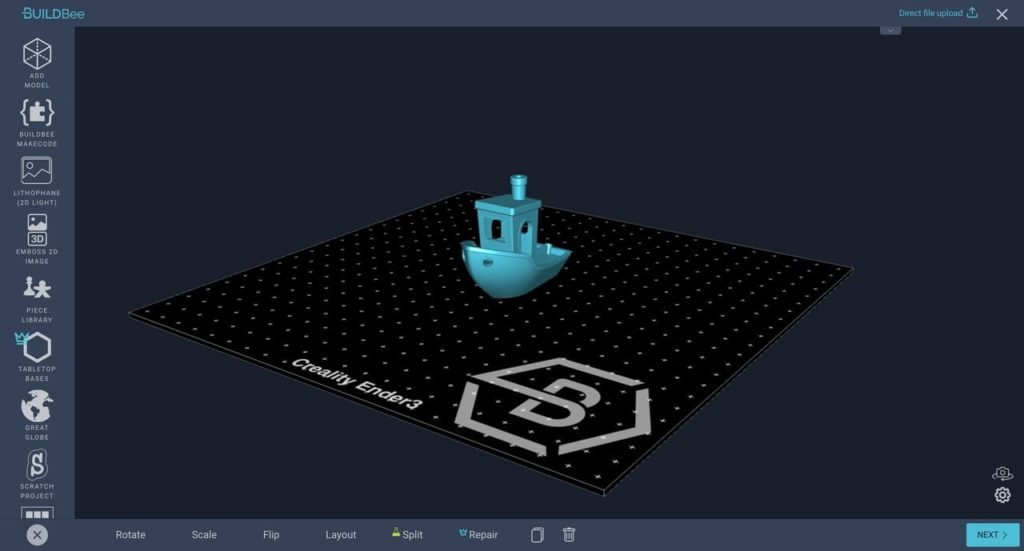

The core of BuildBee is the slicing system, which converts a 3D model into executable GCODE for 3D printers to run. The company has taken steps to simplify this process, which can be quite confusing for new 3D printer operators in most slicing systems. BuildBee terms it as “easy and intuitive”.

Perhaps the most unique feature of BuildBee’s slicer is that it handles both FFF and Resin 3D printers. Normally this is done with dedicated (and usually confusing) software apps, but with BuildBee there’s only one system required.

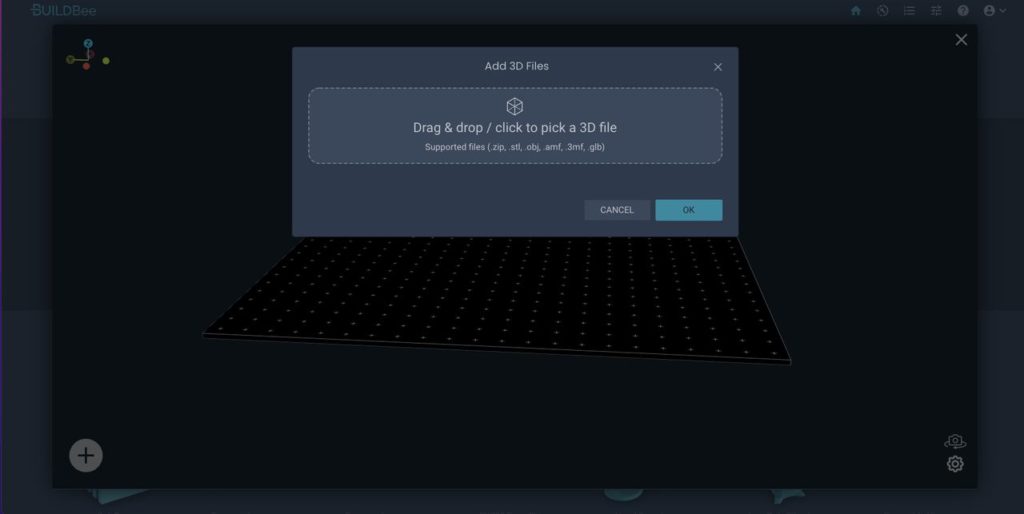

The slicer can accept 3D models directly uploaded by the user, or select from BuildBee’s own model repository.

BuildBee attempts to achieve “perfect printing” by using well tested print parameters for specific 3D printers. As of this writing they list nearly 100 different 3D printer models supported by the system, and they invite participants to assist in adding more. What’s quite interesting is that the list contains a wide variety of gear, ranging from inexpensive desktop equipment to high-end industrial gear like the INTAMSYS FUNMAT HT. They even support some discontinued equipment, like Printrbots and the Solidoodle, for those still operating them.

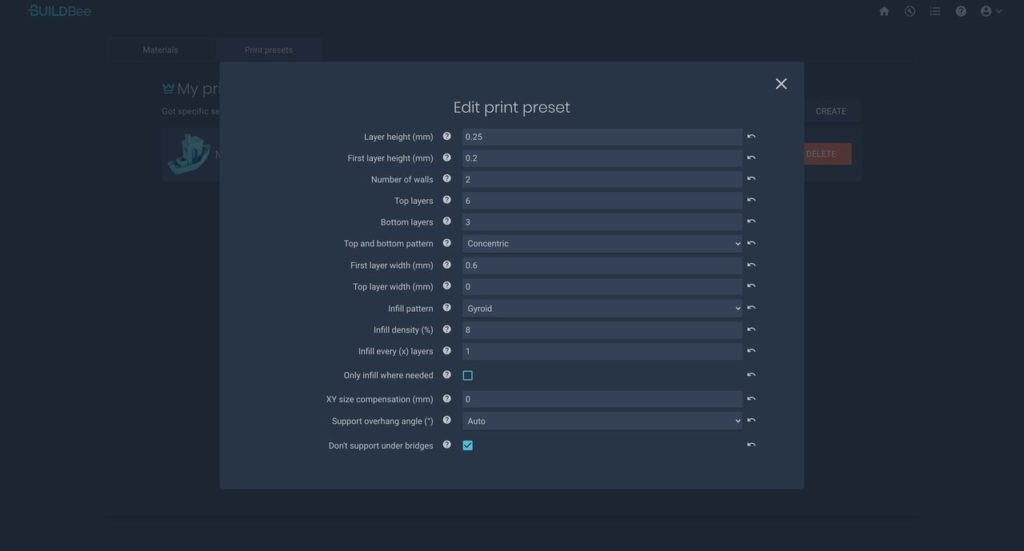

While the BuildBee slicer includes the usual functionality, its presentation is simplified for novice users. That said, they do provide an ability to unhide more advanced controls for those users interested.

What sets BuildBee apart, however, is that they’ve listened to 3D printer operators and included functionality that is simply not found in typical slicing software. Consider these functions included with BuildBee:

- Lithophane creators

- Cookie cutter generators

- Board game piece library

- 2D image to 3D image creator

Those are very common types of prints that many 3D printer operators want to perform, yet typical slicers require you to use separate (and again confusing) third party apps to create the 3D models for each of those. Instead, BuildBee directly includes these functions so that the operators can directly access them.

BuildBee Pricing

BuildBee offers several different plans for using their platform.

The basic plan is totally free, and allows one user to manage one 3D printer, with storage space for up to five 3D models and limits on usage. With this system many operators can easily slice and print 3D models on a casual basis.

For those looking for a more advanced setup, BuildBee also offers an unlimited paid tier priced at only US$6/per month. This level would be ideal for those operating more than one 3D printer, as it allows for unlimited slices, unlimited printers, file storage and GCODE download, as well as support for resin 3D printers.

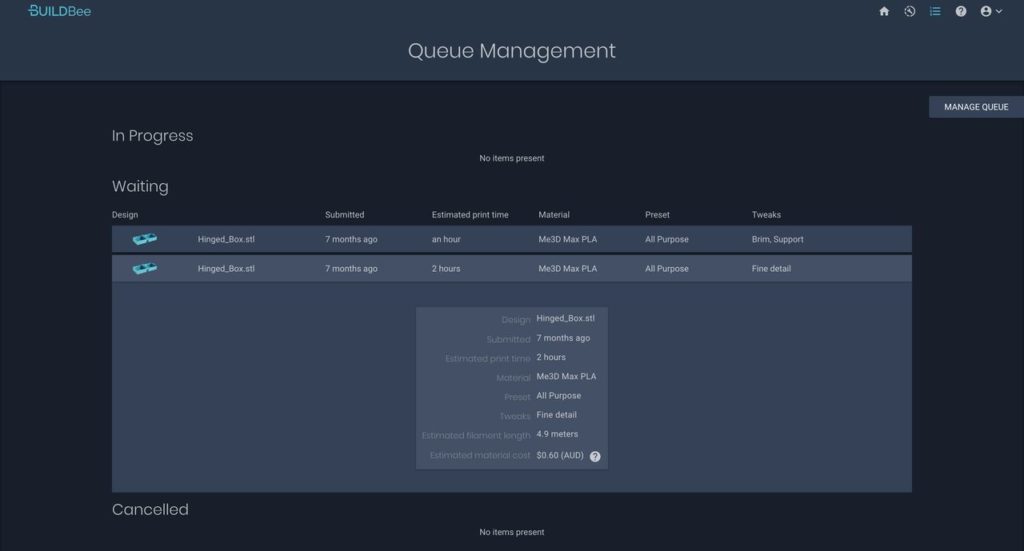

There’s also an ability to create a print queue, and watch a live stream of the print job, if the connected printer has an included webcam or by using the desktop’s camera if running on BuildBee Desktop.

One very interesting advanced feature is the ability to automatically repair 3D models. Often STL files are corrupted, and sometimes the corruption can confuse slicing systems. BuildBee can examine the files and fix them quickly using cloud processing power. Automated model repair is an increasingly rare function, as several popular free third party options have been discontinued, so seeing it on BuildBee’s list is quite attractive.

There’s an ability in BuildBee to intelligently split large 3D models that might not otherwise fit into the 3D printer’s build volume. This is a very welcome feature that solves a problem many 3D printer operators can’t figure out on their own.

Finally, there is a very interesting AI feature that performs 3D model verification to ensure it is printable before proceeding. This, in my opinion, is a very valuable feature because novice 3D printer operators usually don’t have the experience to identify unprintable models. Here BuildBee does it for you automatically.

I’m pretty impressed with BuildBee’s functionality, as it goes well beyond that of most slicing software, particularly focusing on the needs of novice 3D printer operators. There are now large numbers of new 3D printer operators, and they need all the assistance they can get.

If you’re interested in trying out BuildBee, there’s no harm in joining their free basic level. They also provide a free trial of the Pro level for those looking for more advanced features.

Via BuildBee