Aerosint proposed an astonishing TEN material powder 3D printing concept.

Powder 3D printing is one of the most common 3D printing processes. It’s used for both polymer and metal 3D printing, using lasers, binder jetting, electron beams and more to fuse the powder particles together, layer-by-layer.

But there’s one thing all of these processes have in common: they all use only ONE powder at a time. This is because the recoater, which places down fresh layers of powder for subsequent layers, typically pulls material from a storage reservoir filled with one powder.

Single material 3D printing is certainly useful for a great many operations that produce parts in specific materials. It’s the standard in the industry.

The idea of 3D printing in powder with multiple materials is at first a bit confusing. How could you have different materials if you have only one reservoir? How could that work?

A couple of years ago Aerosint did solve this puzzle with their unusual approach to recoating. Their approach was to use a pair of rotating drums. The powder would be selectively applied to the drums, which then rotate on top of the print layer to release the powder. By using two drums, the system could deposit two different powders on the same layer. These would then be sintered in the usual manner.

And it really works. I’ve personally seen 3D prints made using their approach, and witnessed two material parts.

Their approach was so attractive that they were acquired last summer by Desktop Metal. That provided the larger company with a possible method of scaling up the Aerosint technology to production levels: Desktop Metal’s existing production metal system uses a powder approach.

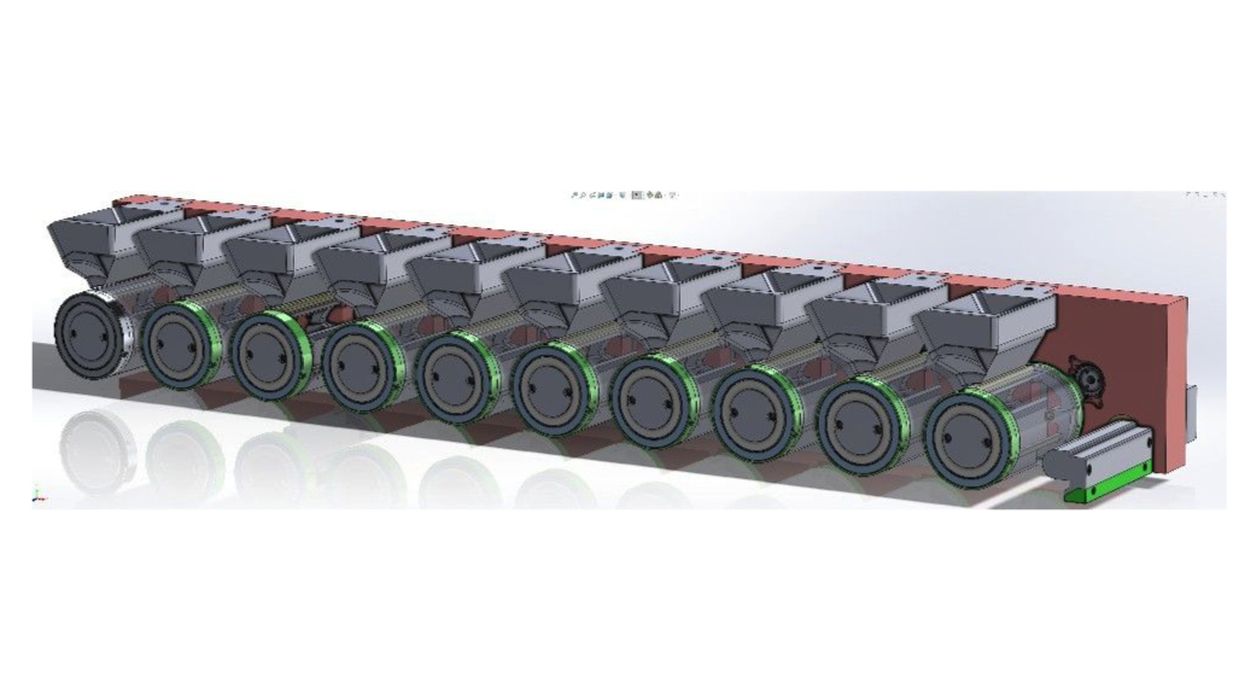

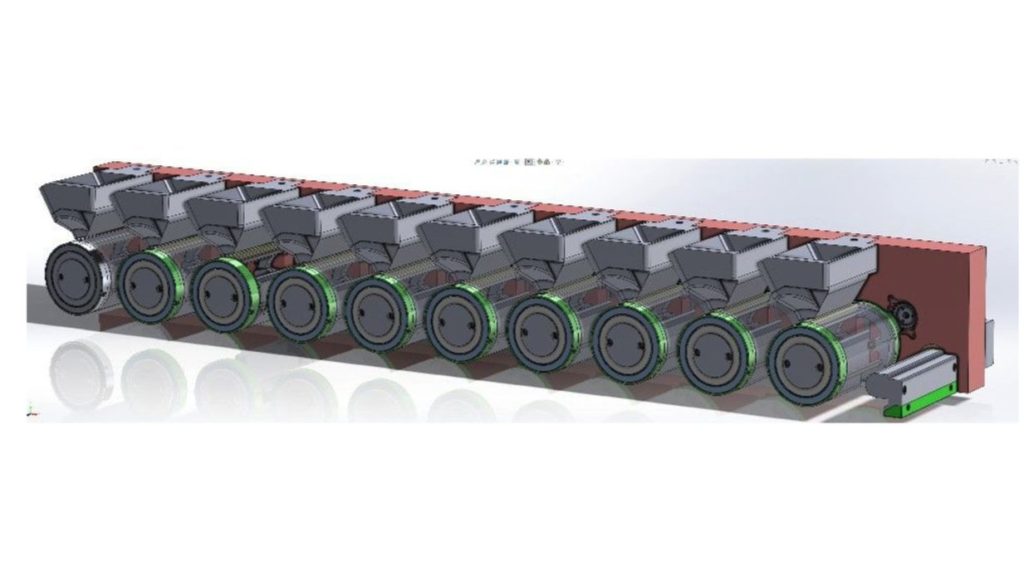

But now there has been a rather provocative LinkedIn post from Aerosint, with the image shown at top. They said:

“10 materials recoater.

Should we build it 🤔🤪? “

Based on what I understand of Aerosint technology, this could be technically possible to build. It would just require a rather long device, but that’s not unheard of in the industry.

Reactions from the post were varied, but many people shouted, “YES”. However, more calm responders suggested there should be specific applications in mind before this monster should be constructed.

I tend to agree with them. There’s no point building something if no one needs to use it. I can imagine applications for parts using two, three or maybe four materials, but ten? What on Earth would you be building with ten different materials?

If the extra materials had some unusual properties, perhaps this might be useful. For example, if one material was electrically conductive, and another electrically insulative, then you could embed basic wiring into a part. A flexible material could enable grips, snaps or hinges in a print.

But even with my imaginative speculation here, we’re still nowhere near ten materials.

To answer Aerosint, I would say no. But I would say yes to a five material system.

What are your thoughts on this?