Sinterit announced a new SLS 3D printer, the Lisa X.

The company has focused on SLS 3D printing for several years, and was one of the first to break the “financial barrier” by offering a low-cost SlS device. At the time, SLS was only accessible to larger companies able to afford the huge prices for the equipment.

Their “Lisa” machine has grown into an entire line of SLS devices over the past few years, with each offerings something quite different. Today their product catalog includes the Lisa, Lisa Pro, the large, industrial NILS 480 and now the Lisa X.

The Lisa X is indeed an evolution from prior Lisa models, and its focus is on speed and production.

The Lisa X offers the largest build volume in the Lisa line at 130 x 180 x 330 mm. Meanwhile, the Lisa PRO’s build volume is somewhat smaller at 150 x 200 x 260 mm.

The big difference, however is the operating speed. Sinterit said the Lisa X can 3D print at approximately 10-14 mm per hour, which is quite fast for an SLS 3D printer, and certainly for a compact device. The full build volume can be 3D printed in less than 30 hours, but most prints will be less than that. This opens the possibility of a one-day cycle for print jobs.

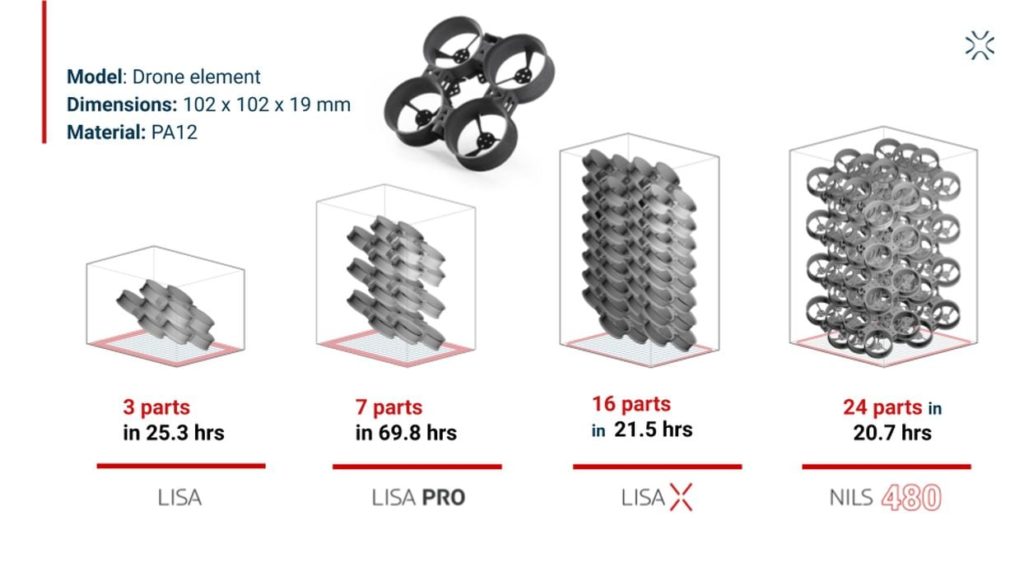

Sinterit provided examples of part throughput for those considering using the Lisa X for production. As with any SLS system, the Lisa X is capable of stacking parts vertically in the build chamber to allow for maximum throughput.

For example, they showed a part of dimensions 22.5 x 18 x 37 mm, a typical size for a connector. As shown in the diagram, the Lisa X can produce 540 parts in only 28 hours, as compared to only 112 parts in 103 hours on the original Lisa 3D printer. That’s a significant advance in throughput. Similar speed advantages are found with larger parts, although the part counts are obviously lower.

How has Sinterit sped up the Lisa X? The device is equipped with a 30W IR laser, which is likely of higher power than the other Lisa models. That extra power means the laser can sweep through the layers at faster speed.

They’ve also added something they call an “air blade” to clean the protective laser glass during print operations. This means operators don’t have to clean the glass after each run, as it only requires cleaning every third cycle.

The Lisa X’s laser spot diameter is 0.650mm, which allows for fine resolution on strong parts printed on the machine. Layer size ranges from 0.175mm down to 0.075mm.

The Lisa X is able to handle nine materials from Sinterit, including:

- PA12 Smooth

- PA11 Onyx

- PA11 ESD

- Flexa Grey

- Flexa Soft

- Flex Bright

- TPE

- Polypropylene

- PA11 Carbon Fiber

The machine also exposes print parameters, allowing operators to tweak settings for specific applications.

The message here is that the Lisa X is ideal for low volume production: its SLS 3D printing process minimizes post processing activities, as there are no support materials to remove. The extra speed of the Lisa X should enable additional application business cases, where they were not financially feasible on prior Lisa equipment.

If you’re looking for a low-cost, high accuracy SLS 3D printer for low volume production, you might consider the Lisa X.

Via Sinterit